|

|

| |||||||

|

Shop Dust Collection

| |||||||||

|

|

| |||||||

|

Shop Dust Collection

| |||||||||

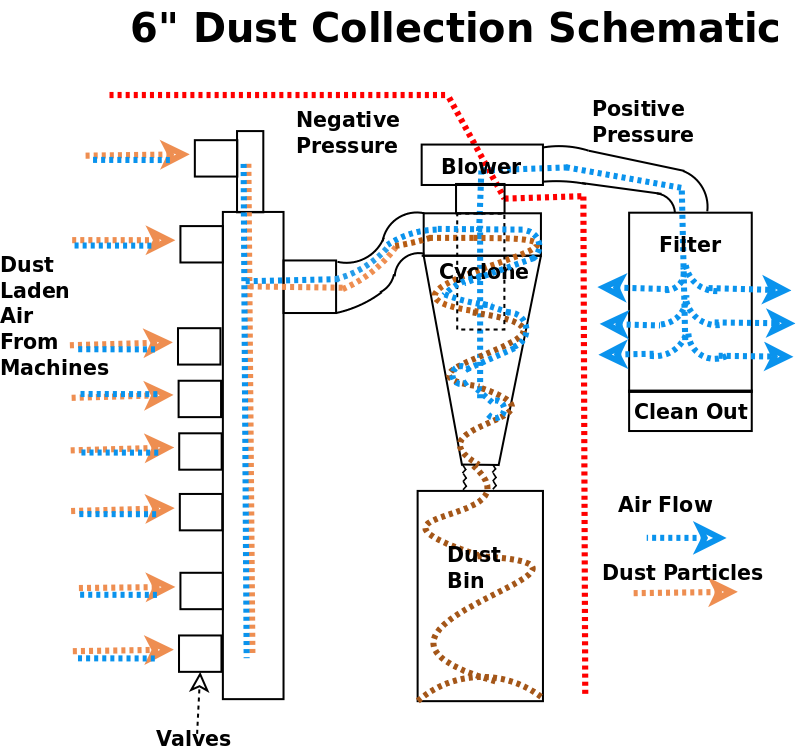

I read up on the hazards of not having dust collection in wood shops and decided I definitely needed to install DC. First I bought a 550CFM Sears 4" DC with a cloth bag, next a Jet DC-1100C with the large cartridge and the clear chip bag, which filters down to about 2 microns. That got most of the chips and dust but left the 2 micron and below stuff, so I bought a Jet air filtration system (AFS-1000) which filters down to 1 micron. That covered all my larger tools but left sanders and smaller hand power tools, so I got the Festool CT-22E (more below). The combination of the three seem to solve the problem.

I have discovered, over time, that a 2" DC system generates more pressure and works best on small hand tools, while the 4" system generates more air volume and works best on large chip generators, planer, table saw, bandsaw. The 4" system seems to do a better job (tool clean, no dust on floor or in air) when there is an air inlet into the tool with the 4" dust port, yielding a "sweeping" effect. Please see my router table dust collection page, Router Dust Box dust collection and BandSaw suggestion page.

550CFM Sears 4" DC

I originally bought a 550CFM Sears 4" DC with a cloth bag filter/dust collector.

It would barely handle one machine and it allowed 30 micron particles to escape into my breathing air.

| Jet DC-1100 | |

| 1 | I needed better filtration and more air volume, so I looked around and decided I needed the Jet DC-1100 (Vortex Cone models weren't available then), it had 1100 CFM and a 5 micron filter. |

| 2 | The DC-1100 came with a 'Y' (6" output from two 4" inputs) which I used until I needed more ports. Added a couple of 4" 'Y's, but that took a lot of space. I built the 4 port dust plenum. |

| 3 | I realized the Jet DC-1100C separator wasn't working correctly (filter clogged really quickly), I added a 'cone' (Tin Man's Hat) which greatly improved chip separation and extended filter life. |

| 4 | Added a brim to the 'Tin Man's Hat'. |

| 5 | Replaced the Jet canister filter with a Wynn filter great move which reduced the filtration particle size by a factor of 10 (.5 micron), and was a lot less expensive to replace. The DC-1100C now catches particles down to the 2-5 micron range |

| 6 | The Jet DC-1100C was against the wall, behind my larger tools so I added a circuit for it with the switch near the center of the room and later a remote fob hanging in the center of the shop. |

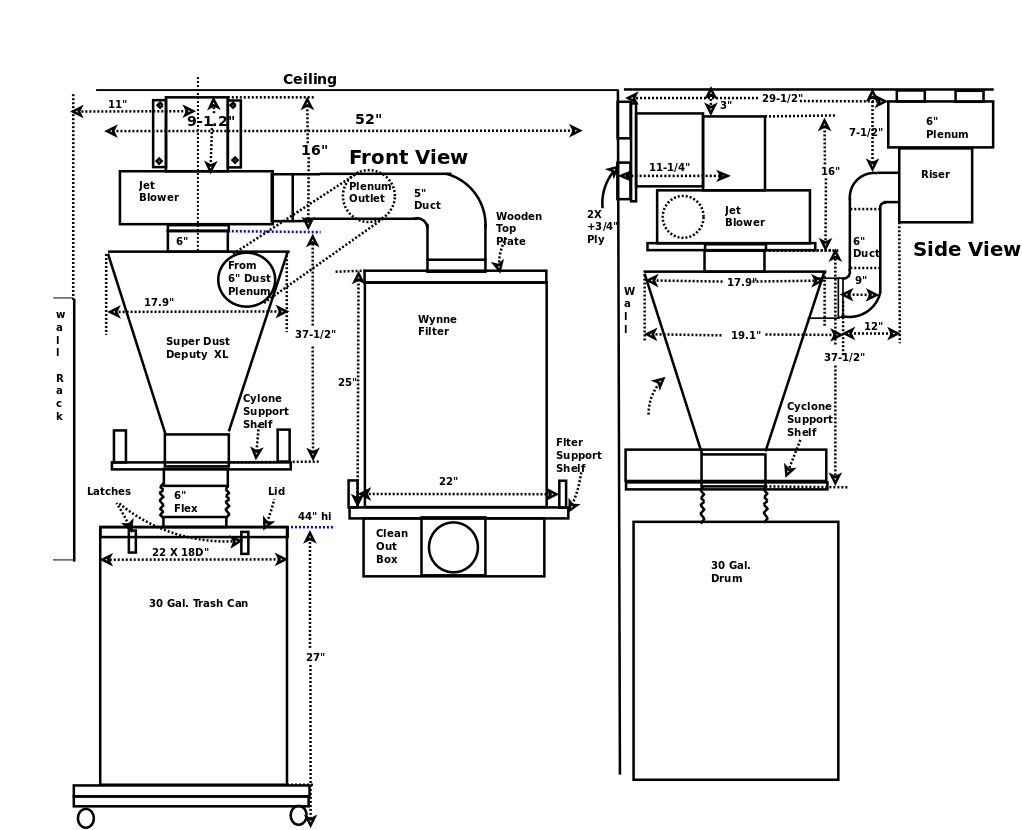

| 7 | Moved the Jet DC-1100's motor impeller to the ceiling and build a new plenum with modular valves directly under the plenum for each of it's five 4" hoses. Link to 4" Overhaul. |

| 8 | I added an extension to the 4" plenum, on the East side of the shop, and another valve. |

| 9 | Added 2 more 4" ports to the main plenum on the West side of the shop and replacing one of the original 4" ports with a 6" port for the bandsaw. |

| 10 | I finally realized that this is really a 6" system DC6. |

| 11 | In 2020 (during the COVID_19 Pandemic), I automated DC6, so that I only need to turn on one of my machines, the correct valve is opened and the blower is started. |

| 12 | In 2021 (still during the COVID_19 Pandemic) I decided to upgrade the blower in DC6. I already had the impeller for the Jet DC-1200, so I bought the 2 HP motor also, and replaced the motor and impeller in the DC6 blower. |

Jet AFS-1000

The JET AFS-1000 catches particles down to 1 micron..

As good as the dust ports on the various machines are, a lot of fine dust, sub 5 micron) gets into the air, so I mounted the AFS-1000 to the ceiling and placed it's input in the center of the room.

The output blows out at a 45° angle so I placed the AFS-1000 so it would blow toward my AC which blows across the room, this gives me a good circulation and feeds the AC with filtered air.

PICS.

Festool CT-22

After researching 2" dust systems I bought the Festool CT-22E and a few of the Festool tools.

I really liked what I saw (except the $PRICE$) and what I see now about the Festool overall system.

The CT-22E works with all Festool tools, the Porter Cable 7 1/4" circular saw, Porter Cable and Dewalt biscuit cutters.

I extended the 2" vac line up and across the ceiling to the center of the area where I do most cutting and sanding, and above the 10" bandsaw.

Originally I placed blast gates in front of each tool access point now I have all the 2" slide valves in one place on the ceiling.

PICS.

Also please see my 2" Plenum and Valves page.

I have been researching and think I can build a cyclone for my shopvac (or CT-22).

Miter Saw Shroud

I built a bench for my Bosch Miter Saw, and then outfitted it with a Dust Shroud.

Router Bench

My router table was originally attached to a wall bench with a 2" dust line from the CT-22.

Now, I have built a roll around router table with a 4" DC connection which I like much better.

Spindle Sander

Now, I have built a 4" dust shroud for the Jet JBOS-5 Spindle Sander.

I don't know what the guys at Jet were thinking, the original dust port didn't fit a 2-1/4&qauot; shop vac or a 4" dust collector.

|

The 2" plenum and slide valves above the door.

|

|

Over head 2" dust system over main work bench area, viewed from South. Note the tee with the capped off end, thats for cleanout of the long run, but, after serveral years, it hasn't been needed. |

|

View of 2" system terminal on the West side of the shop. Notice the red and black cable hanging down, sanders etc are plugged into this power source which comes from the CT-22 DC. When the tool is turned on so does the CT-22. Also note the 4" updraft valves in the background. |

|

The Jet AFS-1000 mounted overhead, output side above the CT-22. It picks up air from the center of the shop and exhausts it to the right directly at the AC. |

|

The Jet AFS-1000 mounted overhead, from the input side. |

|

6" DC system, on the ceiling. you can see the Jet blower and 6" cyclone (behind bandsaw on left), 4" plenum and 7 valves at the top right. I originally built the 4" plenum to handle two 4" valves open at once or one 6" valve. You can see one 6" valve, for the bandsaw, just to the right of the riser. The single 4" extension to the East is not shown here. I alternately refer to this as either 4" or 6" since I mostly use one 4" at a time, but the bandsaw has a 6" valve and the plenum has a 6" cross sectional area. It will work with two 4" valves open at once or the 6" valve open. |

|

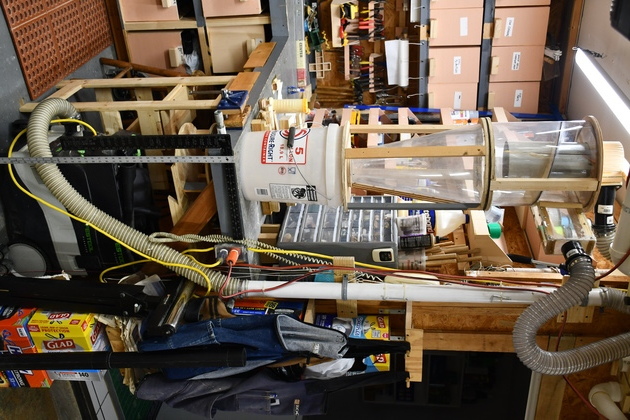

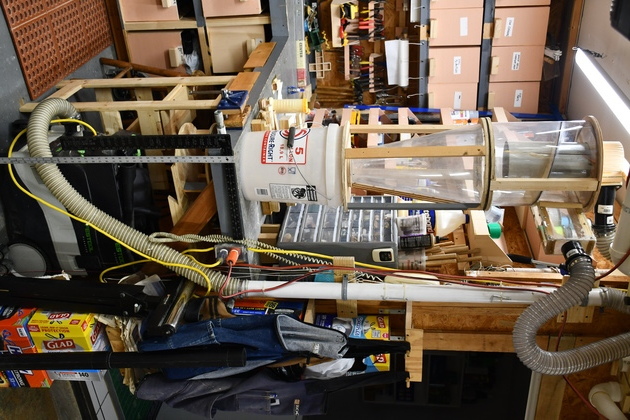

View of main DC below and behind the plenum, valves, and hoses: Jet blower, Wynne Filter (on right), 6" cyclone, 33 gal dust bin.

Two reasons I chose the 33 gal. garbage can as a dust bin:

1. Vacuum won't crush it.

2. Mouth is just smaller than a 39 gal garbage bag (easy emptying).

|

|

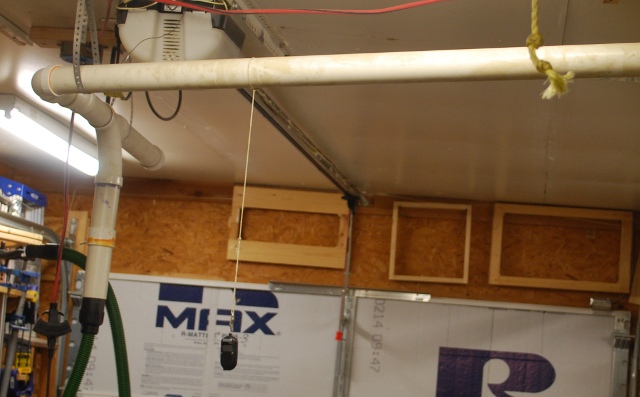

Original 4" plenum, 5 valves, and hoses. The slightly out of focus black fob (Red Circle) with the aqua button hanging down on the left, controls the power to the 4" DC. I have since replaced the remote blower switch and it's fob with an automated system. |