|

|

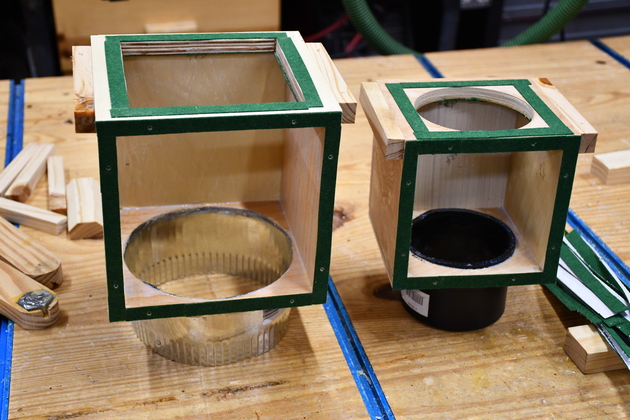

| 6" Updraft Valve | |

|

|

| 6" Updraft Valve | |

| Back Dual 4" Ports | Construction Info |

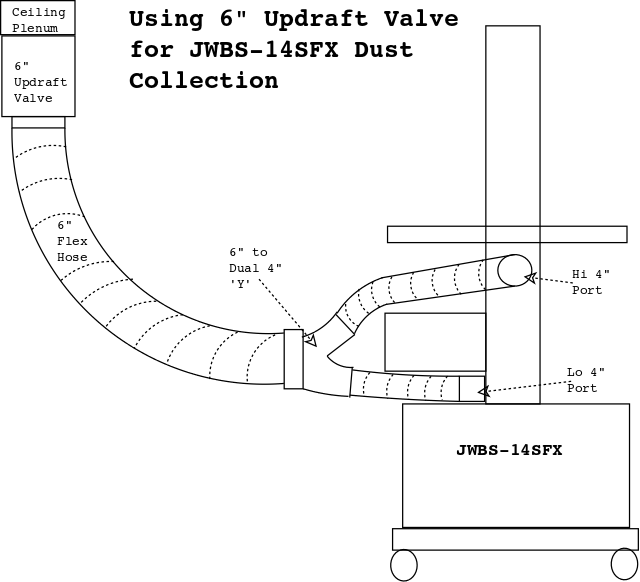

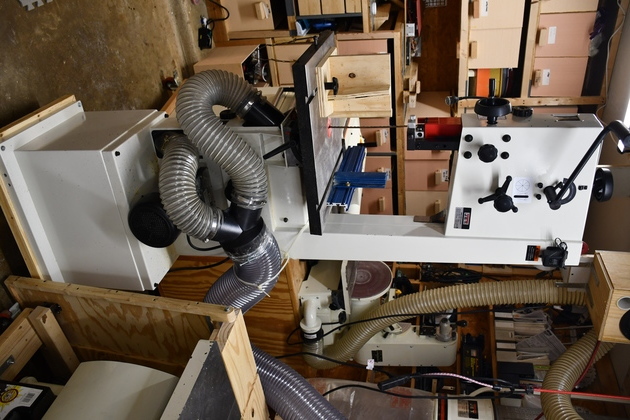

My new Jet JWBS-14SFX requires two 4" ports for dust collection.

I like to dedicate a DC port and valve to each requently used machine and the bandsaw is used a lot.

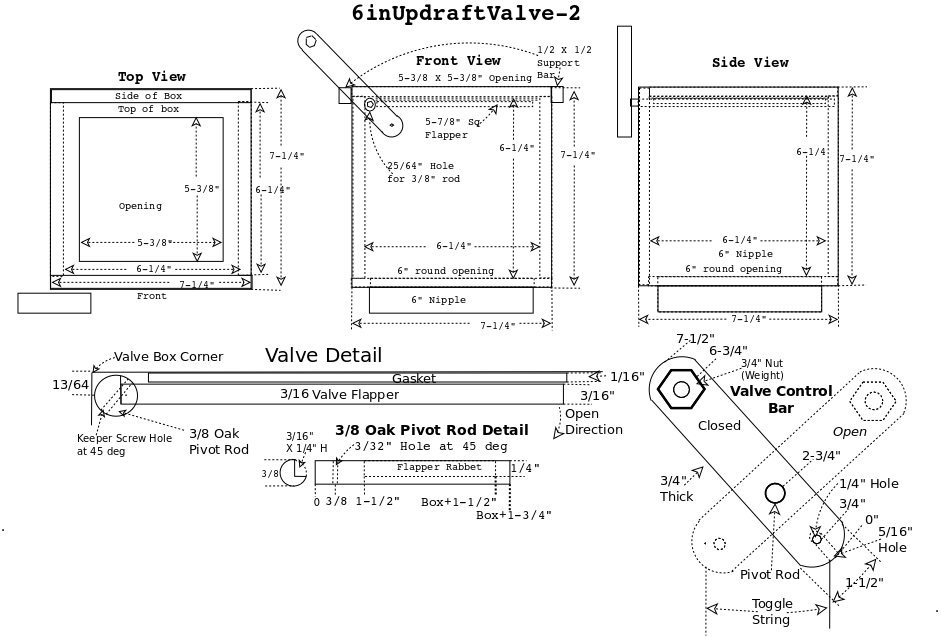

I didn't have an extra 4" port, so I have to expand my DC plenum and add valves.

I am going to replace the #3 4" valve with a 6" valve and hose with a 6" to dual 4" 'Y' and two 4" hoses to the saw, so there is only one valve I turn on to use the saw.

I will also add a 20" extension to the ceiliing plenum, to the North, with two 4" valves and hoses.

|

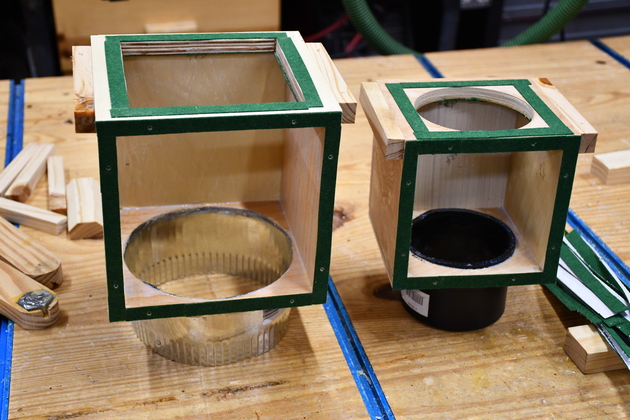

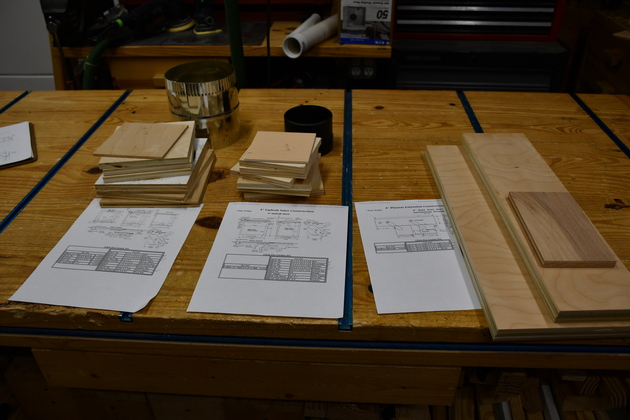

Pieces for the two valves and the new plenum extension laid out on the workbench. |

|

I've cut the 1x2 to length for the two control bars, here I'm drilling the 1-1/8" X 1/27quot; deep holes for the weights. You can see the marks for the round ends on the left end. |

|

Weight holes drilled, next I have to carve out the corners of the nuts. |

|

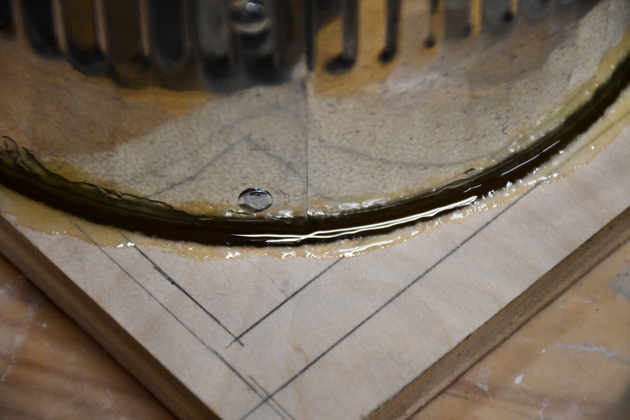

I'm gluing in the 6" and 4" nipples in the valve bottoms. |

|

Closer look at the polyurethane glue. Polyurethane glue foams up and expands so it will fill cracks and make this air tight. |

|

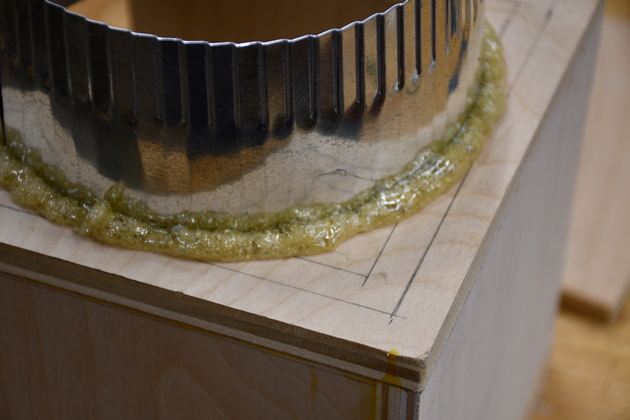

And the fresh polyurethane glue on the 6" nipple. |

|

After the polyurethane glue has expanded and set. |

|

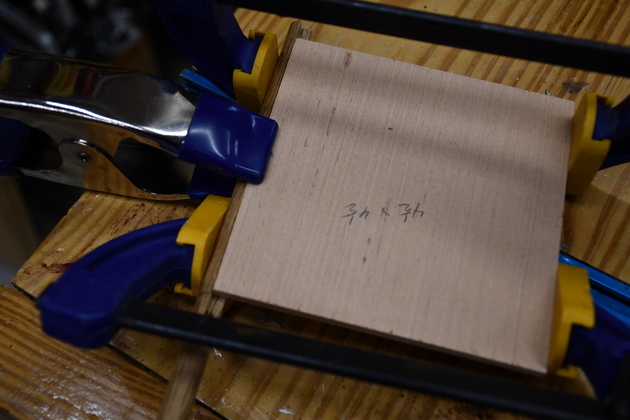

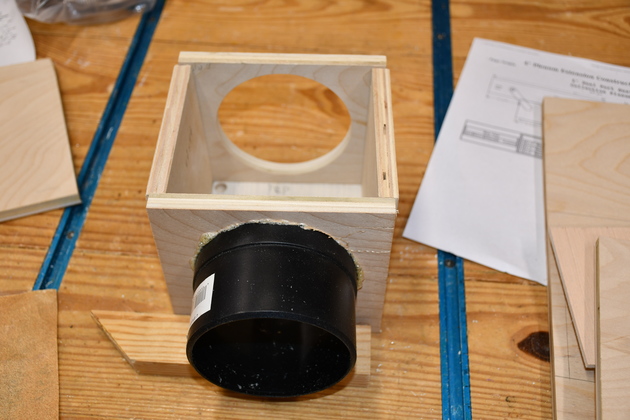

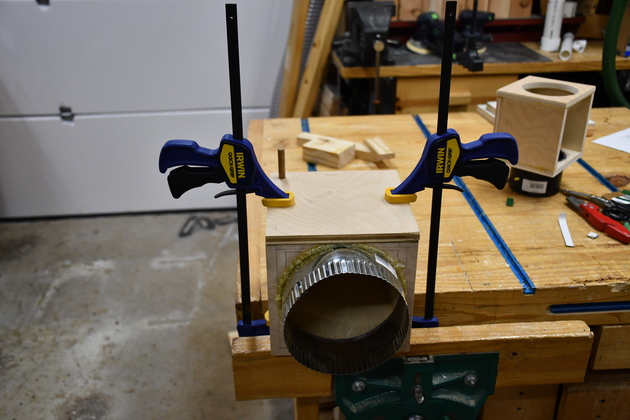

Gluing the boxes together. Here I'm gluing the sides to the back of a 6" valve box. |

|

Note: lots of ClampIts go keep things square. |

|

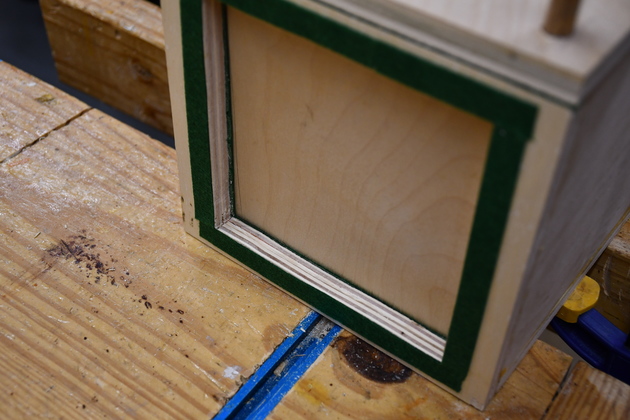

A 4" box being glued. |

|

Both valve control bars. |

|

Here I'm drilling the keeper hole in the end of a 3/8" pivot rod. |

|

I drew where the notch would be milled. |

|

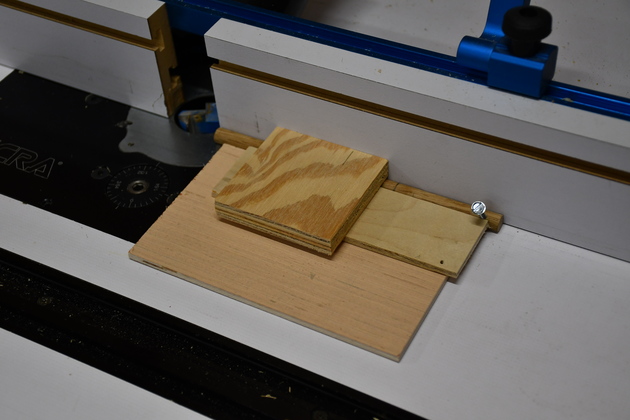

You can see the pivot rod against the router table fence, the plywood makes a holder/push block. You can see I put a small screw into the keeper hole and it's at a 45° angle to the router table. |

|

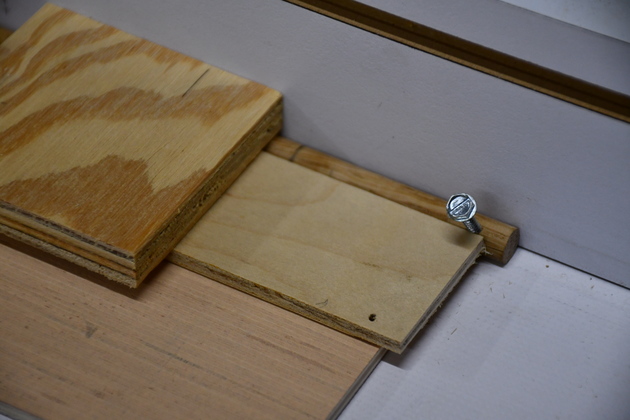

Closer look at the 45° angle of the screw in the keeper hole. |

|

Here are the two pivot rods after milling a rabbet for the flapper. The flapper top surface must be flush with the edge of the pivot rod. |

|

Gluing the flapper to the pivot rod. |

|

Closer look at gluing the flapper to the pivot rod. The lines on the pivot rod are where the control bar and the box will go. |

|

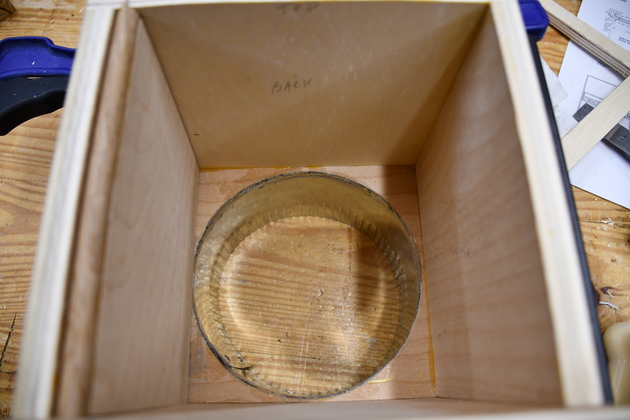

Here is a look at the blind pivot rod hole in the back of a valve nox. Note its about 1/16" from the top to allow for the gasket. |

|

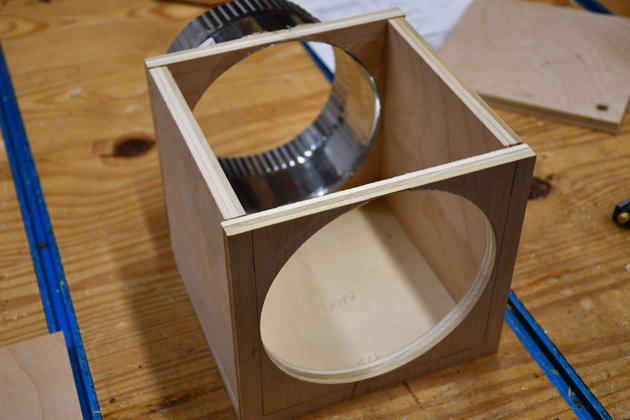

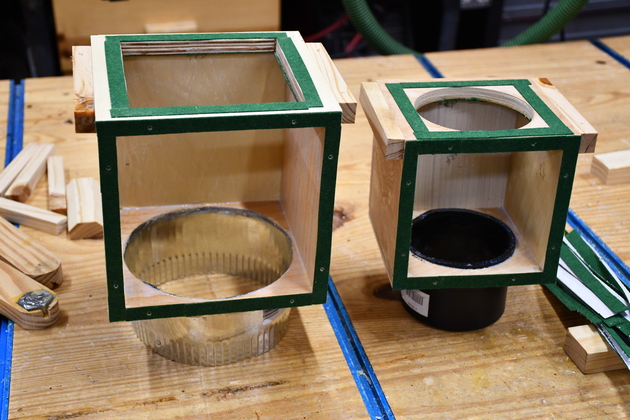

The whole 6" valve box. |

|

A 4" valve box. |

|

The control bars. |

|

Looking down into the 6" valve with the valve open. |

|

Looking at the top of the 6" valve with the valve closed. |

|

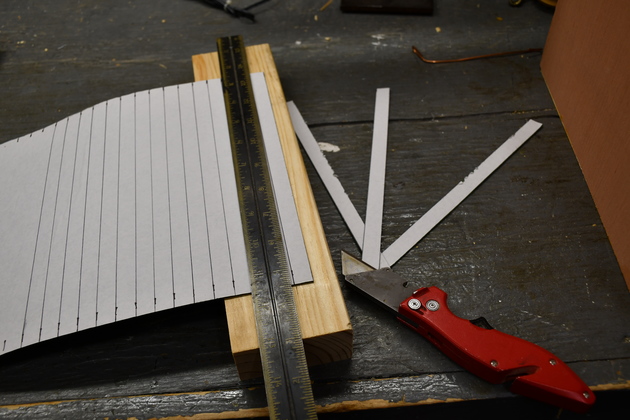

Cutting felt strips for gaskets. These are what I call "stickey backed", hobby felt, you just peel and stick. |

|

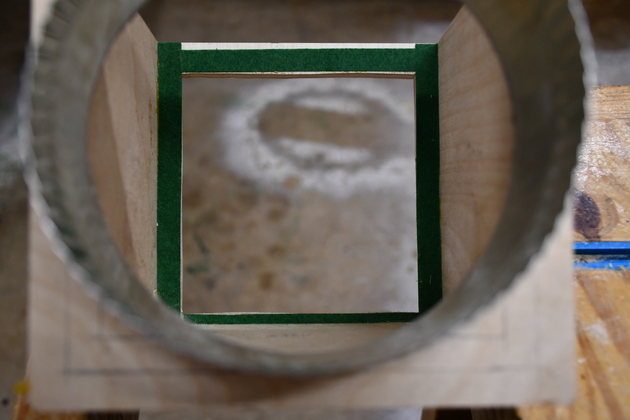

The valve seat. |

|

Looking down into the 6" valve at the valve seat. |

|

The flapper laying on the seat. |

|

Front clamped on to drill screw holes. I line the valve flapper up so it opens and closes easily the clamp and drill. |

|

Gasket on top of valve box with valve flapper closed. |

|

Gluing pelenum extension top on. |

|

I added this little block to give support to the junction of the two plenums. |

|

The two new valves with gaskets. |

|

Plenum, flappers, and control bars being painted. |

|

Old plenum after removing #2 valve. I had put the gaskets on the plenum on the first go-round, now I put the gaskets on the valve box. |

|

Note the 6" valve and hose where the 4" used to be, just to the right of the riser. |

|

The new extension with two 4" valves. |

|

BandSaw with 6" line, 'Y', and 4" to each port. |

|

|