|

|

|

| Dual 4" Extension Plus One 6" Valve | ||

|

|

|

| Dual 4" Extension Plus One 6" Valve | ||

| Dual Plenum Cnst Info | 4" Valve Cnst Info | 6" Valve |

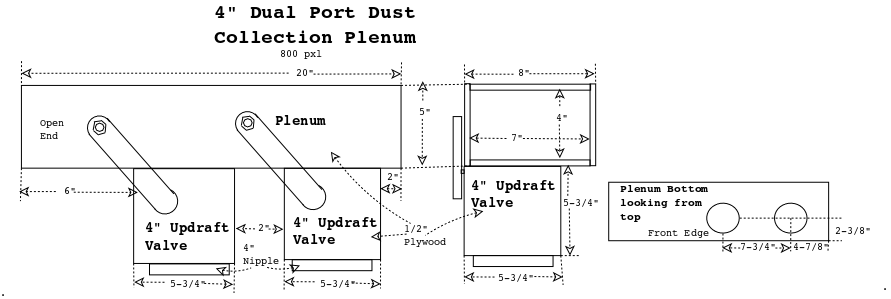

After the 2018 shop re-mod, I began using the roll-around router table, the new bandsaw (needs two 4" hoses), and re-arranged tools, I realized it would be a lot handier to have two more 4" DC ports on the North end of the 4" plenum and replace one of the existing 4" valves with a 6" valve. I like to permanently attach dust hoses to the most commonly used tools. I already had 6 4" ports in the shop, 5 in a row on the West side and one just East of the center.

I decided to replace the number 2 4" valve with a 6" valve to feed my new bandsaw.

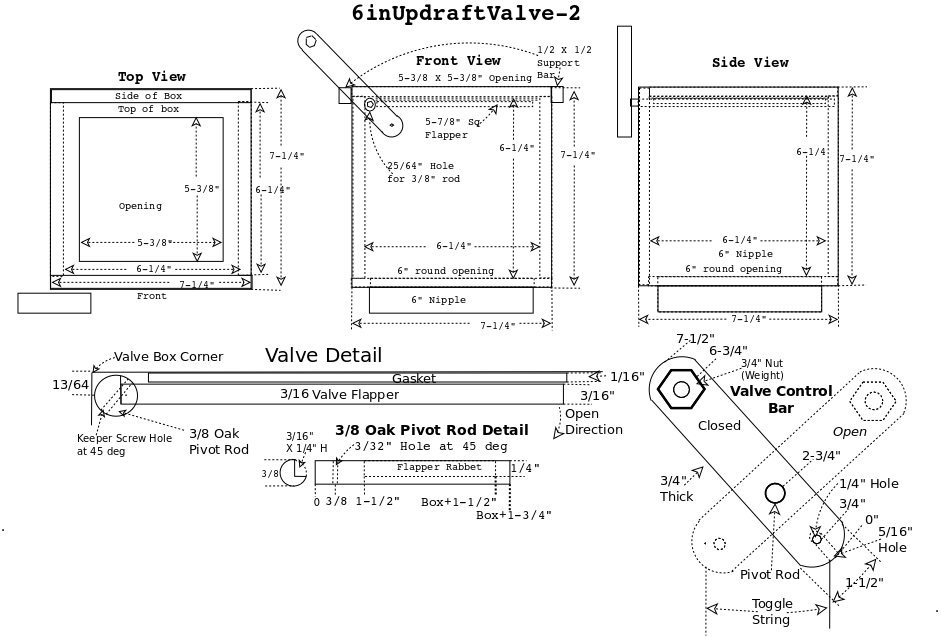

This valve will have a square flapper covering a square hole instead of a round hole.

This will allow me to fit a 6" valve onto the existing plenum, between the riser and the number 3 valve.

Now one of the concerns in a design like this is the small amount of material in the top and bottom when you cut the opening for the air, you can't have the interior cross sectional are be too much larger than the air opening but the valve flapper has to have room to open and close.

The opening is 5-3/8" X 5-3/8" in a 6-1/4" X 6-1/4" piece of plywood.

So I had to make the interior of the valve a little larger than normal.

Of course the concern is that when air rushes through the opening into a larger space (35%larger), the velocity will decrease by 35%.

But the air is rushing upward so, hopefully, very few airborn prticles will be deposited (the inside of the valve doesn't have many flat places except the flange at the bottom around the 6" nipple).

Two more things:

I am changing the design of the valves to increase the top and bottom plywood pieces, makes them a little stronger since there is a large hole ineach.

And I am replacing the metal corner braces that hold the valves to the plenum with a wooden bar, glued to the side of the valve box.

This is less expensive and allows me to reduce the space on each side of the 6" valve.

|

|