| Main Dust Collection Page. |

|---|

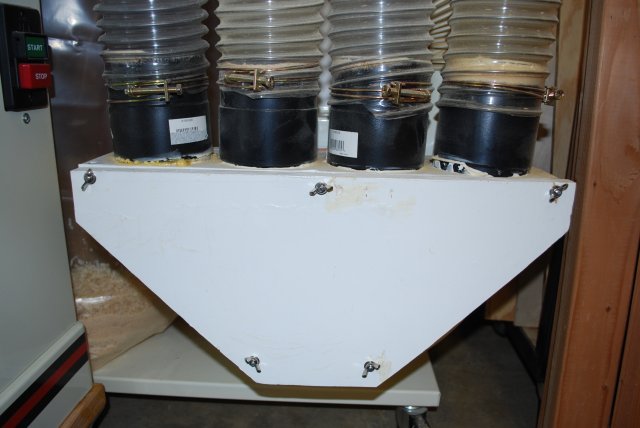

The old 4 port plenum: the whole system takes up a lot of floor space, which is precious at our house. The motor/impeller and plenum were on the floor with the 4 hoses looping up and hanging from the ceiling with bungie cords supporting them near mid point. Each hose has a blast gate on the equipment end, which is inconvenient (since the gate is behind most equipment) to read or switch.

| The 4 port vacuum plenum as it normally is seen. This was replaced by the 4" Overhaul. |

| One of the 3/16" wing nuts. Note the Gorilla Glue on one of the 4" nipples on the top, I cut a clearance hole for each nipple, inserted the nipple and caulked it. Later they started working loose so I started using Gorilla Glue, it seals any air leaks and holds nicely. The nipples are actually 4" couplers sawed in half. |

| One of the hanger bolts. You can see a few metal chips from vacuuming around the drill press. |

| The side of the plenum, you can see the heavy (3/4" plywood) front lid and back. The entire plenum is held in place by the vacuum. |

| The back of the plenum up against the DC-1100's impeller housing. Note the extra 3/4" spacer I had to add so the mouth of the 6" inlet (protrudes about 1 1/2") would be flush with the inside of the pelnum's interior to cut down on turbulence that would create dust piles inside the plenum. |

|

Hoses above the plenum.

Some of the tools have moved around so I probably need to reassign the order.

Each hose has a blast gate at the machine (other) end.

When I get some time, I'm thinking of replacing the 4 port plenum with a 6" hose to the ceiling and making a long plenum (like a pipe organ wind chest) with 4" drops spaced down it's length instead of the 4 hoses now used. The down hoses could be shorter and still allow the movement I have now. Please see the 4" Overhaul<\a>. I moved the whole 4" DC system to the ceiling and added a new 5 port plenum, cleaning up this tangle of 4" hoses. |