03/27/12: Page Origin

I LOVE DRAWERS to put stuff in.

I wanted to call this page "I Love Drawers" but Betty thought I should word it differently.

I recently counted and as of 06/12/21, I have built 76 drawers and 12 tilt-out bins in the house and 57 drawers and 81 mitered plywood bins in the shop.

Here I'll show how I make drawers for workbenches and furniture.

I mostly make flush drawers but I have also made face frame overlay and lipped drawers.

Sometime I build drawers with No Pulls or just finger holes as pulls.

I also build sliding shelves, another kind of drawer.

I use glued Half Blind Dovetail joints at the corners (so far) even though they are sometime Through Dovetails due to the resawed backs not being quite 3/8" thick.

I use 1x for the front (3/4" thick), resawed 1x boards for the sides and back, and 1/4 or 3/16" plywood bottoms.

I just cut a 1/4" X 1/4" rabbet along the bottom edge of the front, sides, and back and glue the bottom into this rabbet after the sides are glued together.

BTW, the inside bottom rabbet helps me keep the piece orientation straight during dovetailing, I use the rabbeted edge as the reference and flush it up against the guide.

Porter Cable OmniJig

I attempted to order a new dovetail bit for my Porter Cable Omnijig and discovered that Porter Cable has DISCONTINUED all Omnijigs and parts???

I don't understand why a "reputable" manufacturer like Porter Cable, after spending a lot of money on development, would discontinue a very high-end tool and all it's components.

Even if it wasn't selling well, they should keep parts available.

I notice that Rockler is still selling Omnijigs, if it is discontinued, why???

Rockler must have a warehouse full, so they have to get rid of them but the buyers can't get parts!!!

I really like the Omnijig for fixed space dovetails, it supports the router, it's easy to learn, it has good dust collection, good design, but why did they quit selling it?

Anyway I'm going to try another manufacturer's 1/2" dovetail bit, as long as I use the fixed space templates it should work to make simple drawers.

Leigh makes a 7° X 1/2" router bit, it has a 8mm shank, and I have a 1/2" to 8mm collet.

NOTE: I finally found bits for the Porter Cable OmniJig at Tools-Plus.com, on the web.

I've ordered some and we'll see what I get!

I received my new Porter Cable brand 7° dovetail bits for the OmniJig and they are exactly the same as the one that came with it, Hooray for Tools-Plus.com!

Following Are Samples of Drawers I Have Built

|

Heavy duty drawer, with partition, I made for storing bullets (very heavy), and brass.

You can see the dovetails clearly in this pic.

The glued-in partition helps strengthen the drawer.

The sides and back are full 3/8", I normally resaw 1x material in half then across the jointer once, leaving 5/16" but in this case they are thicker, for additional strength.

I also needed the max 3-1/2" depth so I didn't put the bottom in rabbets in the sides and back, the front is rabbeted for the bottom.

You can see the edge of the bottom at the outside bottom of the drawer.

|

|

Pile of drawers, ready for handles.

The most drawers I have made in one session.

|

|

12 drawers and their cabinet, painted, and ready to install.

|

|

In the mortiser bench storage bay is the bullet and brass cabinet and it's drawers installed and loaded.

Each drawer can hold up to 70 lbs, for a total of 840 lbs, it typically has about half that amount in it.

One of my machine benches must be tough so I can add whatever I need after its built.

Here is a link to the building page for the bullet and brass storage cabinet.

|

|

The two center drawers and the drawer on the right contain over 60lbs of bullets each.

Note the cabinet doesn't try to tip over!

|

|

Lathe bench with gouge, chuck, and tool drawers.

Also a sliding adjustable support for the vacuum pickups.

The lathe weighs about 300lbs., the chucks, gouges, and other tools probably weigh another 100lbs.

This is what I mean about tough benches.

|

|

A lathe gouge drawer open.

|

|

A chuck and tool drawers.

|

|

A chuck and tool drawer open.

|

|

Drawer under the workbench, note no pulls.

|

|

Flush drawer in the end table, also no pulls, there is a 1/2 x 1/2" pine bar glued to the bottom, just behind the front edge, as a drawer pull.

More No-Pull Drawers.

|

|

Drawers in the mortiser bench.

Note the home made handles (drawer pulls).

Also note the bullets and brass stored in the bottom, part of my handloading activities.

|

|

One of the closet drawers open.

|

|

A little closer view of low profile handle.

|

|

The now defunct multi-bench.

This bench was 32" square and holds 4 different power tools with 9 drawers.

These drawers contain drill bits, sand paper, loose tennons, and a lot of attachments for hand power tools.

I replaced the multi-bench with two benches (below) because I needed more flexibility, this thing only fit one place.

I built a new bench for the 10" bandsaw and the spindle sander using only the left side drawers from this bench.

Link to new bench pic .

|

|

The drill bit drawer in the multi-bench, the drawer is still being used in the bandsaw/spingle sander bench (below).

This drawer is 26" deep, behind the bits are countersinks, plug cutters, and self centering drill bits.

|

|

Drill press with lift-off storage, and new bandsaw bench replacing the multi-bench.

Link to the Machine Benches Page with a little more info on the new bench.

The drawers in the bandsaw bench are what was in the left side of the multi-bench.

Drill bits and DP accessories moved to drawers in the Drill Press Lift-Off Storage cabinet.

|

|

Lipped drawers in the drill press storage cabinet, left.

The drawers in the bandsaw bench, right, are flush, like most of the drawers I make.

Take a look at the Floor Drill Press Storage Cabinet page.

|

|

Closer look at lipped drawer fronts.

|

|

Larger lipped drawers.

|

|

Lipped and flush (inset) side by side.

Yes, I have been known to do stuff like that.

The drill press storage cabinet is very shallow, front to back, so I made the drawers as deep as possible.

Also note the top thckness of the cabinets.

The right, bandsaw cabinet, bears the weight of two power tools, the drill press storage cabinet doesn't have any tools on top of it.

|

|

Drawers in lift-off storage cabinet under floor drill press.

Link to project page for Drill Press Base and Storage.

In the background you can see the old multi-bench.

|

|

Drawers in the mitersaw bench.

I built a shroud around the back of the mitersaw which works fairly well (a great improvement over no shroud at all).

You can see the basic structure of my machine benches in this mitersaw bench pic, the 1 1/2" thick top and the 2x4 frame with plywood panels glued into rabbets.

Also note, to the left of the mitersaw bench, 3 tools with caster bases.

|

|

Vanity installed with slider open.

|

|

Side pic of overlap drawers in chest of drawers, showing pine inset panels on side and front of drawers.

|

|

Test Bench

Note the pull-out work top and pull-out keyboard shelf.

|

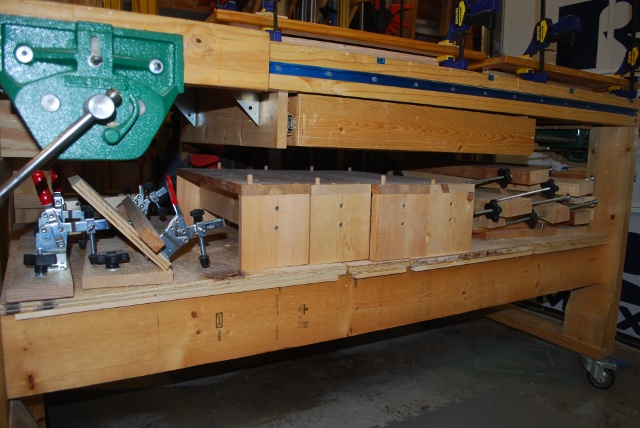

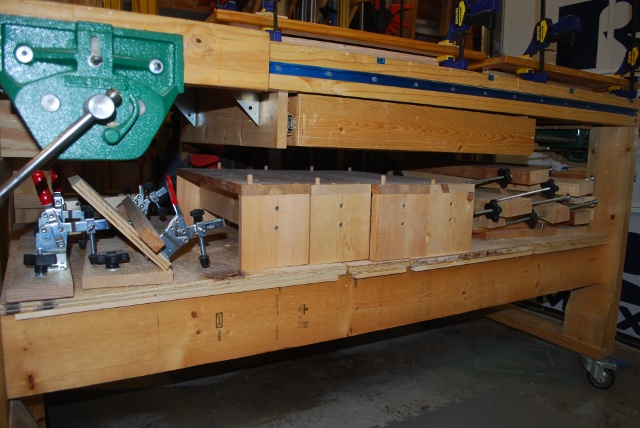

Dovetail Jig Storage

Pictured here is my original dovetail storage in the sander bench.

I have rebuilt the

dovetail storage into the sander bench with a spring loaded lift.

|

Sander bench with dovetail jig stored.

The top drawer holds extra sandinng belts and tools for the sander.

The bottom drawer holds the dovetail jig tools, extra templates, etc.

|

|

The dovetail jig is on the workbench, the sander bench, with drawer extended, is ready to receive the jig.

|

|

Dovetail jig moved to the sander bench drawer, still extended.

|

|

Closer look at stored dovetail jig on it's own slide out shelf (another kind of drawer).

The shelf consists of two 1.5" X 1.5" (ripped 2x4) and a 3/4" plywood shelf on slides.

Note the 1/2" panels glued flush into rabbets so the inside wall is flat, and the bottom stringers tying the end frames together, this is classic how my machine benches are constructed.

|

|

The dovetail storage shelf in the out position.

|

|

Close look at dovetail jig on its storage shelf pulled out.

Note the locking pin on top of the jig (upper red circle), it is inserted through a hole in the side of the bench (lower right red circle) into the slide out shelf (note lower left red circle), to lock the shelf in while moving the bench.

The locking pin is a wooden knob drilled for a 1/4" dowell then glued in.

|

|

The locking pin in place, holding the drawer so it doesn't slide out when bench is moved.

You can also see the end frame structure of the bench with it's 1/2" plywood glued in panel and how the lower frame section is notched for the horizontal stringers.

|