08/18/14: Page Origin.

When you need a board that is thinner than standard lumber: (1 by or 2 by), and you don't want to waste a lot of wood using a planer, you can resaw a thicker board into the thickness you need.

I do a lot of resawing for various projects but mostly drawer sides / backs and thin panel faces for laminating to plywood.

For instance, I recently needed a 5/8" thick X 3" wide board for a wine glass holder, so I resawed a 1x4 (3/4" by 3-1/2").

The bandsaw always leaves a rough side so when you saw the thickness you will need to leave enough extra wood for one pass across the jointer or planer (at least 1/32 to 1/16").

Considerations:

|

|

| 1 | Bandsaw blade is sharp, and properly tensioned.

|

| 2 | Bandsaw blade is exactly square to the table (should be explained in you bandsaw's manual).

|

| 3 | Resaw guide is exactly parallel to the bandsaw blade (see Resaw Guide Page).

|

| 4 | Lumber you start with is not cupped or warped, a little cup can be taken out using the thickness planer.

|

| 5 | Lookout for knots, they add character but can cause problems if they're loose and come out.

|

| 6 | Thin panels with knots frequently shatter in the thickness planer.

|

In the pics below I'm making some drawers so you'll see references to backs, sides, and fronts.

The same procedures apply to all resawing.

BTW: The background for this page is a panel I made by Resawing and Edge Joining.

Drawers

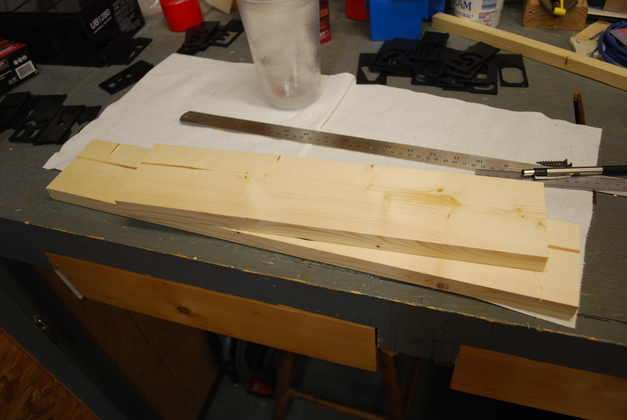

|

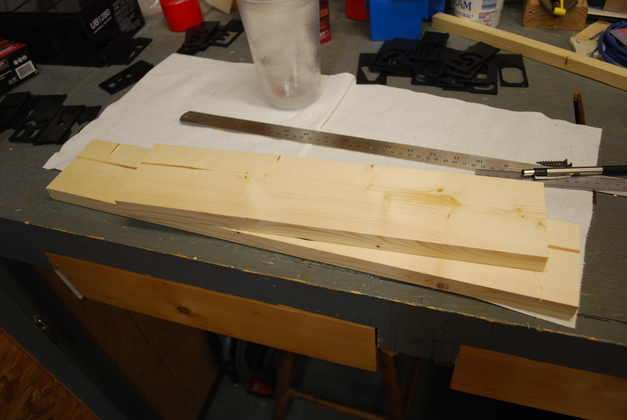

Boards cut to length for drawer back, and sides.

The back must be exactly 1" shorter than the front, check my drawer construction page for more on that.

The front will be full thickness or 3/4", the sides and backs will need to be resawn (sawn exactly in half down the long way) to get the correct thickness.

|

|

The drawer sides and back will be resawn from 3/4" boards, ending up about 5/16" thick.

I mark the center of a side or back then resaw the board in half, edgewise.

Since 1/2 of 3/4" is 3/8", I set the marking wheel to 3/8", try it from both sides so I know its in the center.

The saw's kerf is .025", I'll remove 1/32" (.03125") from each sawed off piece.

The board was originally 3/4" (.75") so the resultant width of each side is .75 / 2 = .375 - a planer cut (1/32 or .03125) - 1/2 the kerf (.0125) = .31875, just a little thicker than 5/16" (.3125).

Here I'm using a marking wheel to mark the center of a board to be resawn.

|

|

Since the marking wheel's cut is very narrow and hard to see, I remark with a .5mm pencil to see it better when I saw.

Even though I use the guide, the mark helps me keep it exactly straight.

|

|

Here is a board marked and ready to resaw.

|

|

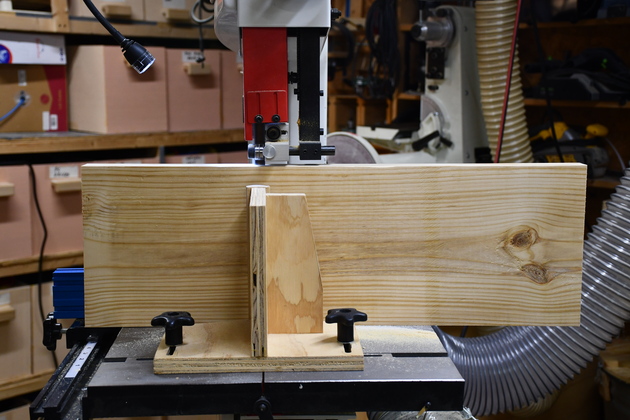

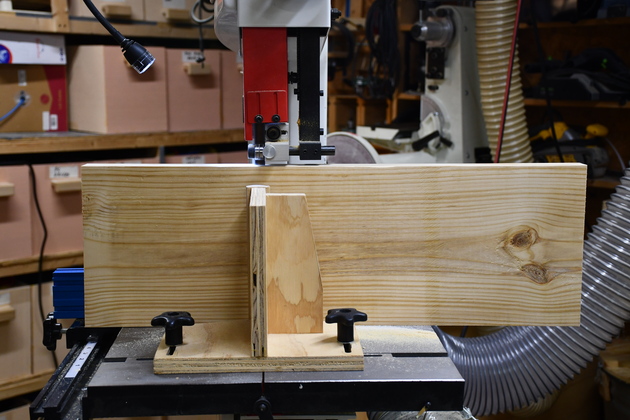

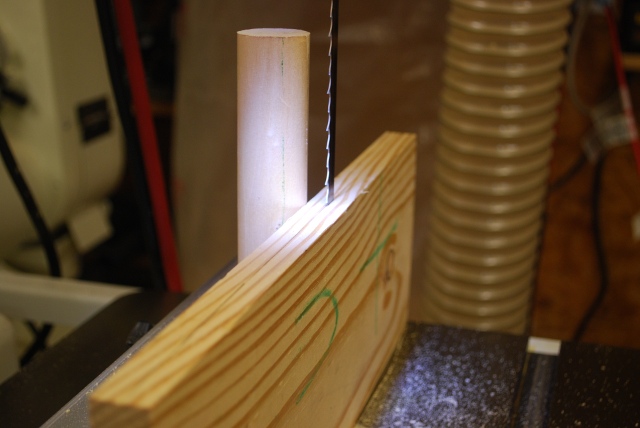

Resawing a 1x6.

|

|

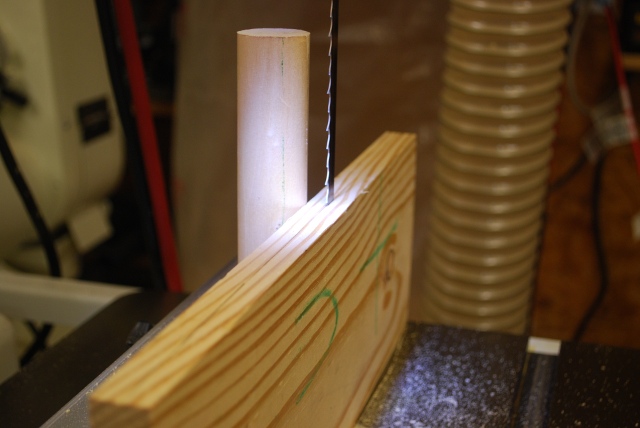

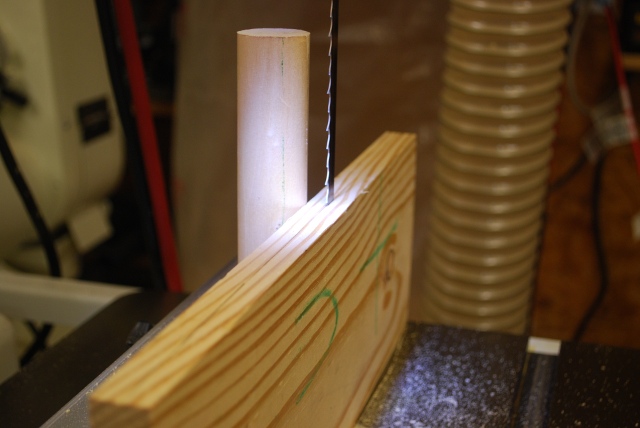

Here I'm resawing a 1x into two < 3/8" thick boards.

You check that the resaw guide and bandsaw blade are both at vertical (right angle to the bandsaw table), before you start.

You must start with boards that aren't cupped, or warped and hold them against the vertical resaw guide.

Here is the page on my resaw guide.

I had to stop the saw for these closeups, the motion confused my auto-focus.

|

|

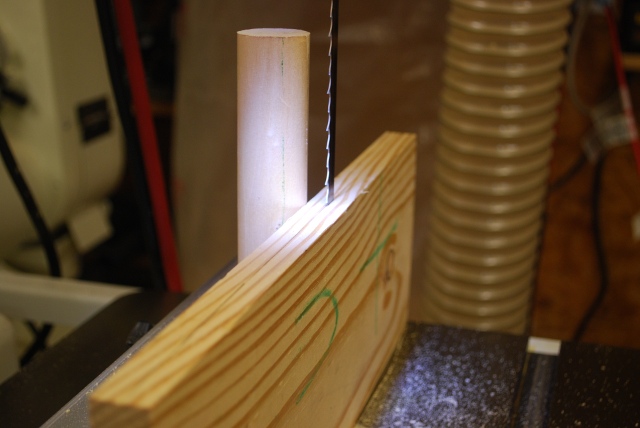

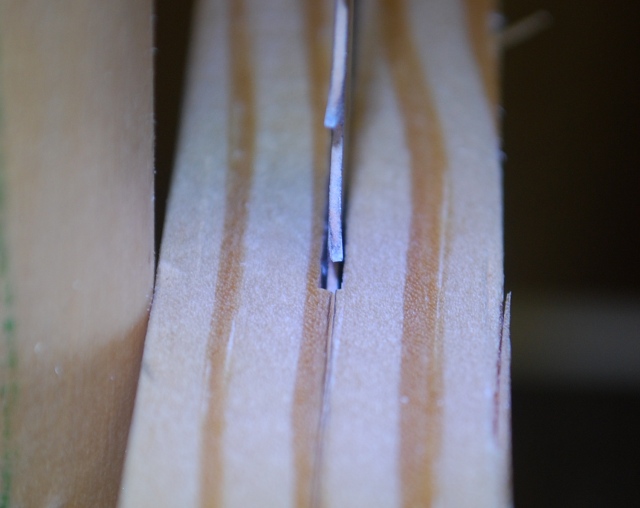

Closer look at the blade sawing the line.

Since I'm going to use both sides of this board, I'm sawing down the center of the line.

Note the blade's kerf is wider than the mark (.5mm = .0197")

The blade's width is .025" but I don't think this takes the teeth's set into consideration.

I'll try to go back and make a partial cut and measure the resulting kerf!

|

|

BTW: Here is a close up of ripping to a specific width, notice the edge of the blade is on the line (thats a .5mm line).

I am ripping a drawer front (1x6) down to 5" plus 1/32" (for jointer clean up).

|

|

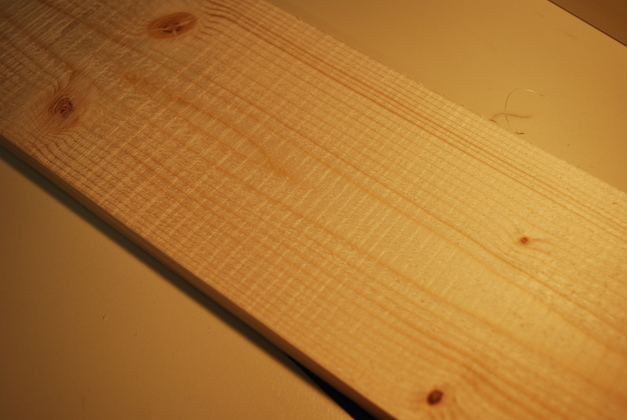

After resawing on the bandsaw.

This isn't a great pic but you can just see the bandsaw blade marks on the resawed board face, one pass across the jointer set to take off 1/32" will remove all traces of the bandsaw (if I was careful when I sawed).

|

|

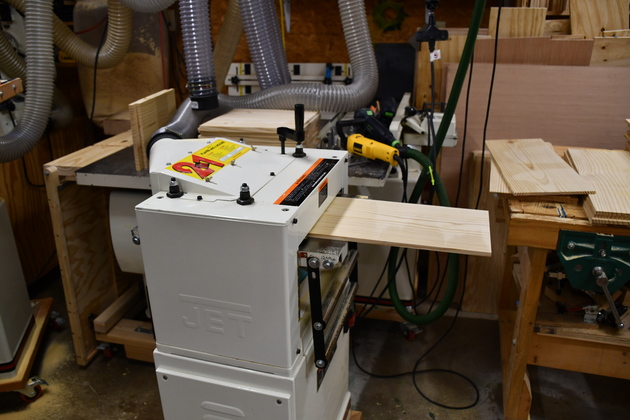

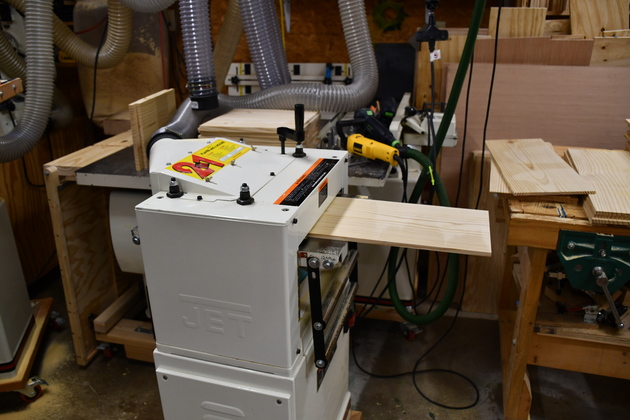

Running the resawed boards across the jointer or through the thickness planer to take off 1/32"

One pass across the jointer is usually enough if you didn't wander around too much while sawing.

You'll note, I blocked the guard back when doing this, the resawed boards are so thin they go under the guard and don't push it out of the way.

|

|

Here I'm running resawn pieces through the thckness planer, it guarantees the thickness and gets rid of the bandsaw marks.

|

|

A little different angle, showing a planed piece coming out of the planer.

|

|

Voilla, no more bandsaw blade marks, it leaves the drawer side or back about 5/16" thick which is fine for everything I've done so far.

Of course you could make the sides/back as thick as you want but you would waste the remainder of the original board.

|

|

Here are the fronts, sides, and, backs cut to length and resawed to the proper thickness, ready to cut the bottom rabbet.

|

|

Here are the fronts, sides, and, backs cut to length and resawed to the proper thickness, ready to cut the bottom rabbet.

|

|

Here I'm resawing a 2x8 for a 3/8" thick drawer side or back.

|

|

The long look at resawing a full width 2x8.

|

|

Currently I've been using these feather boards to keep the bottom against the resaw guide.

|

|

The last cut, I get three 3/8" thick slabs from a 2x8.

Note how the left edge of the blade is on the mark.

Of course they're 1/16" thicker than required so I can plane them.

|

|

A little farther away view.

Note the thin sawn off slab on the right.

|

|

And planing the resawn board so the thickness is exactly 3/8" and the surface is smooth.

|

|

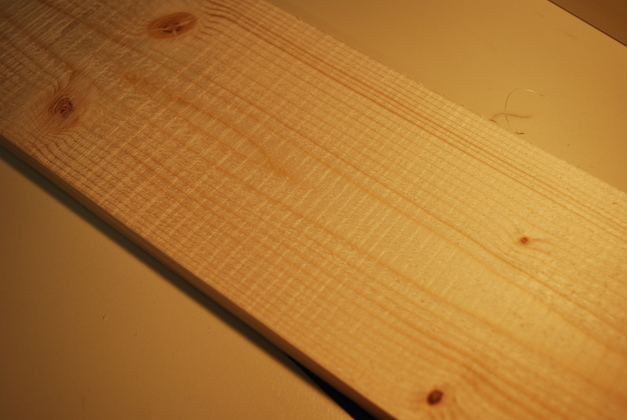

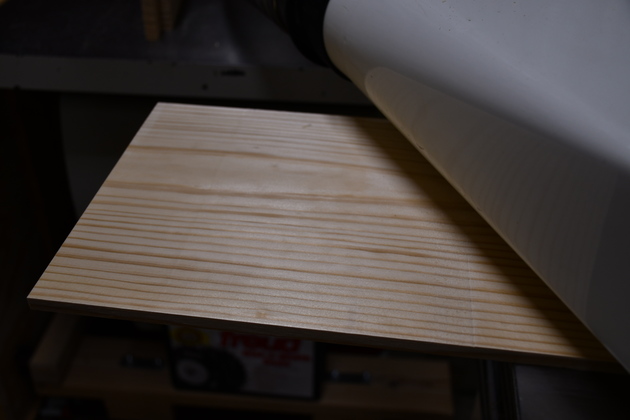

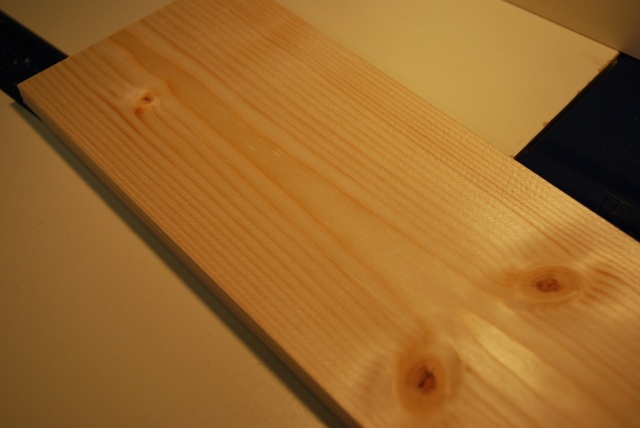

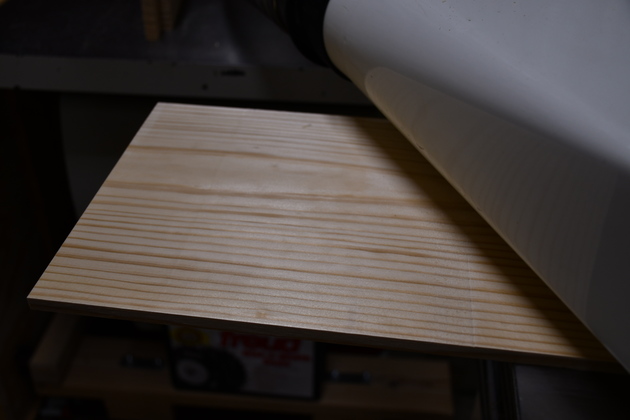

The newly resawn face.

If you look close you can see the bandsaw marks.

|

|

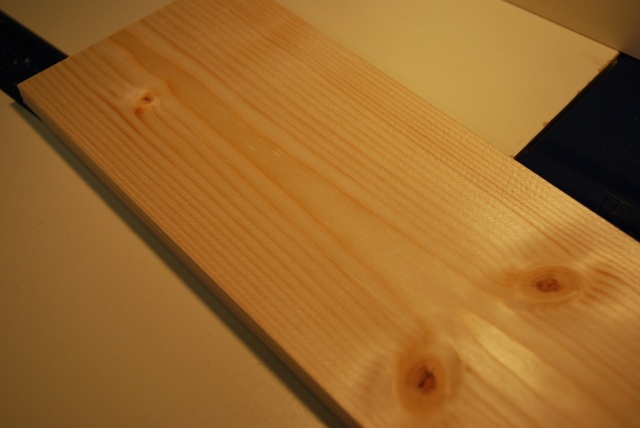

After planing, smooth and uniform thickness.

|

|

The finished 3/8" thick drawer sides and backs.

Also notice the thin sawn off slabs on the right, I use them for laminating to prlywood for inset panel faces..

|

Inset Panels

|

Resawing another 2x8 for making pine inset panel faces.

|

|

The slab I'm sawing is 1/8" + 1/16" thick, the extra 1/16" is to plane off to remove bandsaw marks.

|

|

After resawing off a thin panel I plane the bandsawed surface so it is smooth, ber fore resawing again.

|

|

Here I've marked a remaining slab for two 1/8" plus 1/16" thick slabs.

|

|

Heres a 1/8" plus 1/16" thick panel going into the thickness planer.

|

|

The panel passing through the planer.

|

|

And after resawing and planing voilla, 1/8" thick slabs.

These may be edge joined to make wider panels.

|

|

A stack of 1/8" thick panel faces ready to laminate.

|