| |

|

|

|

|

Making 1x from 2x Lumber

|

05/16/17: Page Origin.

I'm machining most of the 1x from 2x lumber because the price difference per board foot is dramatic.

Please see my Page on Price Per Board Foot.

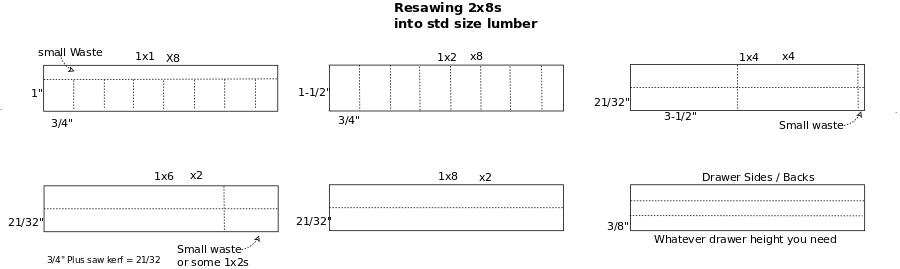

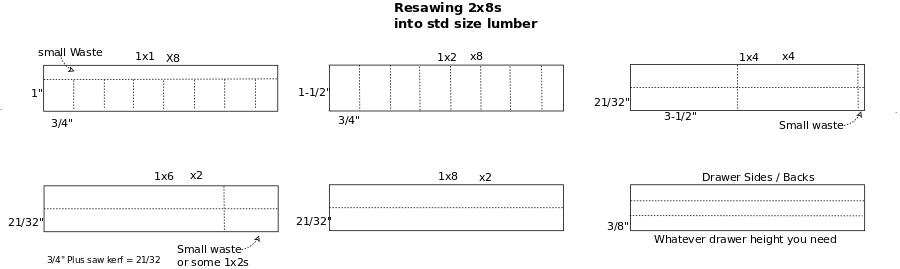

When I resaw a 2" thick board (1-1/2" actual) I loose 3/32" (kerf (1/16") and one jointer pass (1/32")) leaving 21/32" thick instead of 24/32" (normal 1x board).

I also loose a little due to large knots but that doesn't negate much of the savings.

I have a bandsaw, planer, table saw, and 6" jointer so I'm going to use 2x8s, cut to len, rip, and, resaw.

Usually the smaller pieces are easier to resaw.

This means my 1x will be 21/32" instead of 24/32" (3/4) but otherwise most stuff should match.

The more difficult part is resawing across the 7-1/2" dimension because I have to handle the entire 2x8 with minimum previous resizing, but it they are short it shouldn't be too difficult.

I could resaw 2x10s also but I don't need that width right now.

I am concerned about long term stability but, we have some indicators, the grain is straight and the humidity is fairly low, about 7-9%, I did find one board at 11%, but that was the exception.

The select 1x wood I have from Lowes measures about 7%.

One note, the wood drys much faster after you machine it to 1x.

All the cutting across the 1-1/2" dimension can be done on the table saw, the resawing across the 7-1/4" dimension must be done on the bandsaw.

I have a project beginning which I'll try this on, so pics are coming.

My concern about stability is due to most of the 2x8s I find are Southern Yellow Pine wich is the strongest and heaviest pine, but it also wants to warp, cup, and bow.

A better choice would be fir, if I can find fir 2x8s.

|

2x8s fresh from Lowes, ready to begin.

|

|

2x8s cut to length.

The longer 2x8s (center) will become 1x3s for the corner verticals of a night stdnd.

The shorter 2x8 on the left will become 9" long side horizontal braces in the frame.

|

|

This piece has a couple of bad knots on the left, but the rest of it is certainly usable.

The large tight knots are typical for 2x construction lumber.

Except for the knots the grain is mostly straight and pretty.

|

|

Two of the longer 2x8 section about to be ripped into 3" sections.

|

|

The 4 on the right are the 3" wide 2x and will be resawed into 1x for two night stand corner verticals.

The waste piece on the far left has been ripped into a 1x2 for the lower front bar of a night stand.

|

|

The ripped 3" wide 2xs are marked for resawing.

|

|

Closer look at the pencil marks.

|

|

Resawing a 2x into 2 1xs.

Ripping to 3" width first makes this step easy.

|

|

Close look at the saw blade working.

You can see the pencil mark I'm following.

|

|

Resawn lumber after one pass across the jointer to clean up the bandsaw marks.

|

|

Closer look at the surface.

|

|

One of the interesting things about resawing, is knots really show the mirror images.

These are two 1x3 ripped from a 2x8, resawn, then run across the jointer.

Its almost a shame these will be painted over.

|