| |

|

Bullet and Brass Cabinet under mortiser

|

Drawers Open Showing Bullets and Brass

|

Bullet and Brass Cabinet

|

06/02/12: Page Origin.

I had numerous kinds of bullets and brass stored in various places around the shop, it was a problem, so I figured I needed to get organized and build some kind of centralized (and sturdy) storage.

I buy most of my bullets from Montana Gold, in cases, and my brass from Starline, in cases.

I did some measuring and realized that cases of brass or bullets took up similar volumes.

So I decided to build a storage cabinet for both.

Naturally it would have lots of really strong drawers (bullets are lead, lead is heavy).

I measured the volume of the cardboard cases that Montana Gold shipped in, inside USPS "if it fits it ships" boxes each holds less than 70Lbs.

I decided that a drawer with the inside dimensions: 3.5" deep, by 6" wide and 16.5" long would hold the same volume, I just needed it to be strong (remember, we're storing lead).

Since I have some smaller amounts of bullets and brass, I glued a partition in the center of the drawer, this also makes it stronger.

I use full extension, 100 lb. slides so I can get to the stuff in the back of the drawer and it'll hold it up with 60+lbs of bullets.

Some of the bullets and brass were under my mortiser bench which looked like it had enough space for everything if I use it efficiently.

I designed a cabinet for 12 of the above drawers to fit into the storage space under the mortiser bench.

How I build drawers and handles

|

I had some bullets and brass stored under the mortiser bench (357SIG, 125gn, Montana Gold bullets, yellow bin, under Lyman cob), 9mm 115gn FN Montana Gold in grey tub, and .45 185gn LTC in white box with yellow post it label.

Eveything else contains brass.

This space is where the bullet & brass storage cabinet is going to end up.

I moved the extra Lyman cobb to the tumbler storage area in the loading bench.

|

|

I had more bullets stored in the loading bench, but I really wanted to use the space for loading tools.

|

|

How I build drawers and handles

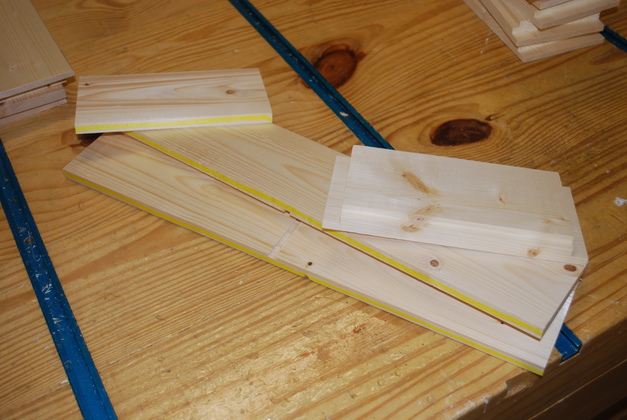

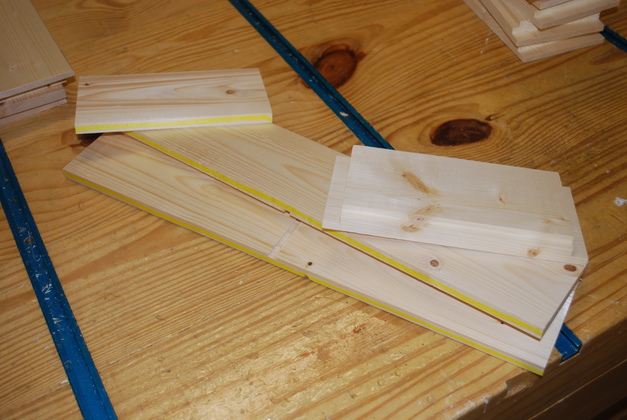

Drawer pieces cut out and ready to dovetail, the sides and back are resawed from 1x material and after one pass across the jointer are about 5/16" thick.

Note: the front (on top) is rabbeted on the sides to conceal the slides and rabbeted on the bottom to conceal the drawer bottom.

The sides and back aren't rabbeted for the drawer bottom, since it will be glued directly to the bottom edge.

You can see the slot cut into the center of the side for the drawer's partition.

I also marked the bottom edge of the sides and backs with a yellow highlighter to help keep them oriented while dovetailing.

|

|

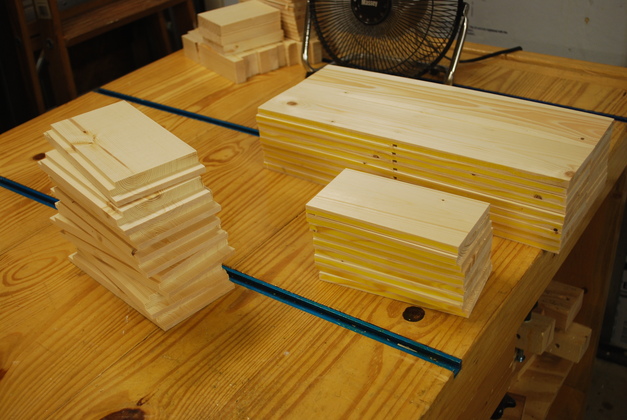

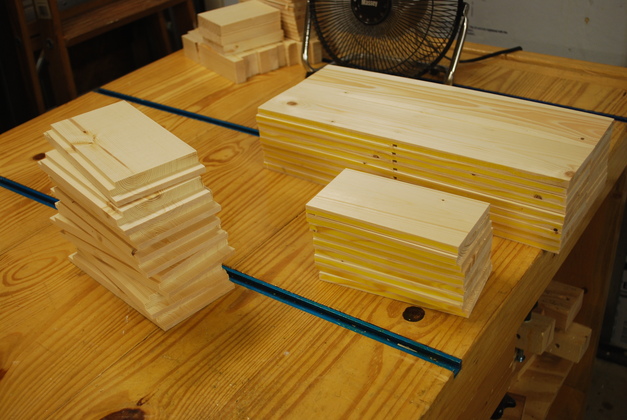

Pieces for all 12 drawers cut and stacked.

Note: the bottom edges with yellow highlighter.

The drawer fronts are stacked on the left, you can see the side and bottom rabbets clearly.

|

|

All set up and ready to dovetail.

This is a Porter Cable 16" Omnijig which they have discontinued, and won't even sell parts for it, this is really not the way a reputable manufacturer behaves.

How I build drawers and handles

|

|

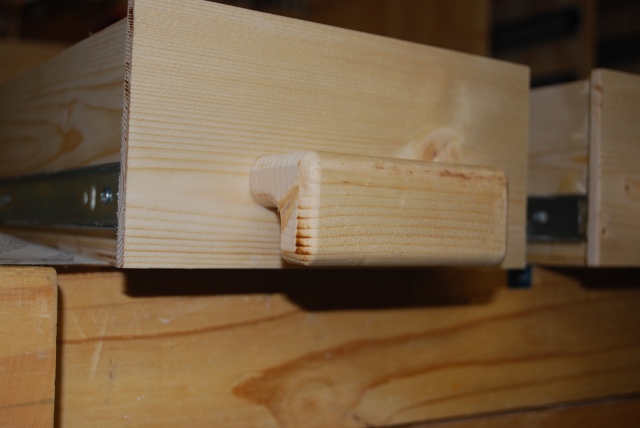

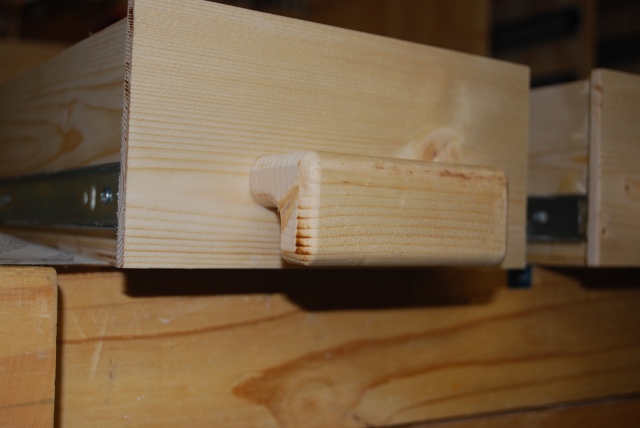

One drawer, glued up, with the partition glued in.

The slides haven't been installed yet, but you can see how the front is rabbeted to hide the slides.

You can also see the bottom glued onto the flat bottom edge of the sides, instead of in a rabbet (I did this to increase the usable depth of the drawer).

|

|

Back end of glued drawer.

|

|

All drawers glued and piled, ready for handles, slides, and cabinet.

|

|

Drawer front marked for drilling handle screw holes, I use the same jig to mark the drawer front as for marking the handles below.

I use 1-5/8" coarse wallboard screws to mount the handles.

I allowed space above the handle for a label.

|

|

Marking handles for pilot holes.

The pilot holes make accurate aligning the handles with the holes in the drawer front a cinch.

|

|

Drawer pull installed, ready to paint (How I Make Pulls.

Note I left room above the handle for a label.

This also shows how a recessed drawer is made, the rabbeting of the front hides the slides.

|

|

Cabinet sides and bottom layed out for marking.

Top, bottom, and end pieces are 3/4" plywood, interior partitions are 1/2" plywood.

|

|

Slides apart and ready to mount in cabinet.

I have to mount the slides before I assemble the cabinet, its a real pain if you try to mount them in a tight space and get them straight.

|

|

Cabinet ready for test fit.

I've never put this many drawers in so tight a space before, this may be interesting.

The top, bottom and sides are 3/4" plywood, the vertical partitions are 1/2" plywood, it will also have a 1/2" plywood back (not yet installed).

This thing is built to hold up to 720 lbs. so it has to be beefy.

|

|

The cabinet glued with painted drawers around it.

I paint all the projects in the shop with clear, water based polyeurethane.

|

|

Cabinet in mortiser bench ready for drawers.

Note: the bullet brass storage cabinet isn't screwed to the mortiser bench frame, it's mass takes care of keeping it in place even when several drawers are fully extended (gravity CAN be your friend).

Remember, each drawer can hold 60+ lbs. so the total cabinet can weight up to 720 lbs.

The mortiser bench has 300 lb. casters giving it a theoretical max weight capacity of 1200 lbs.

|

|

New storage cabinet in place in the mortiser bench storage bay, with drawers loaded.

Note: these are flush front drawers just like the ones in the mortiser bench above the bullet and brass cabinet.

No slides are visible on either drawer type due the the side rabbeted drawer front.

|

|

Brass and bullets stored in new cabinet.

On the left is 9mm and 357SIG brass, center is .30 Cal. bullets and right is .40 165gn FN (Frontier) bullets.

The ziplock bag in the 9mm area contains once fired brass, all other is new starline.

Note, on the right hand side the overlap of slides by the front, the top drawer is closed, the next one down open, you can see how the slide is concealed.

|

|

Another set of drawers open showing brass and bullets stored.

The center drawer is all the unloaded M1 carbine brass I have (most is loaded), behind it is my .308 brass.

Both drawers on the right drawer contain .45 Montana Gold bullets, we shoot a lot of .45 both ACP and AR (same bullet).

|

|

Bottom drawers, left is .45AR (Rim) brass (new starline), middle is 9mm 115gn FN, and right is an entire case of .45 185gn Montana Gold hollow points.

The partially open drawer in the center contains 357SIG, 125gn, Montana Gold.

|

|

The loading bench now has just tools and loading support stuff, the bullets and brass are all in the new storage cabinet.

|

|

Another look at the loading bench with just loading tools.

I'll be using it today.

|

|

Here is the Lyman cobb stored in the loading bench tumbler area.

|