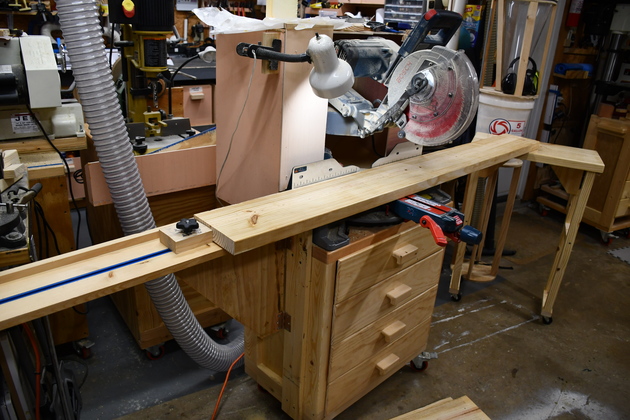

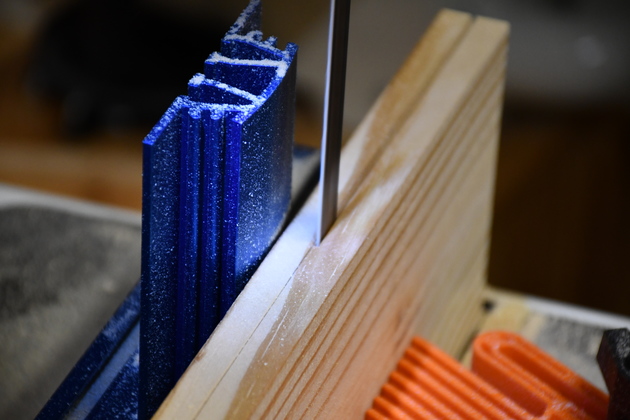

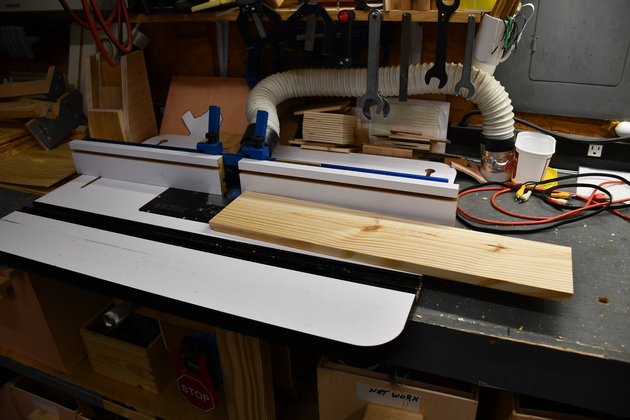

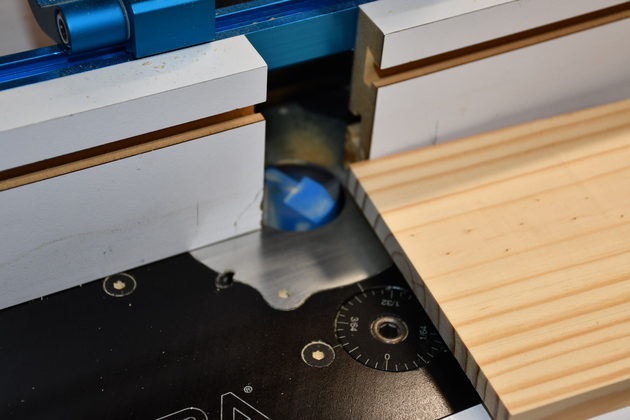

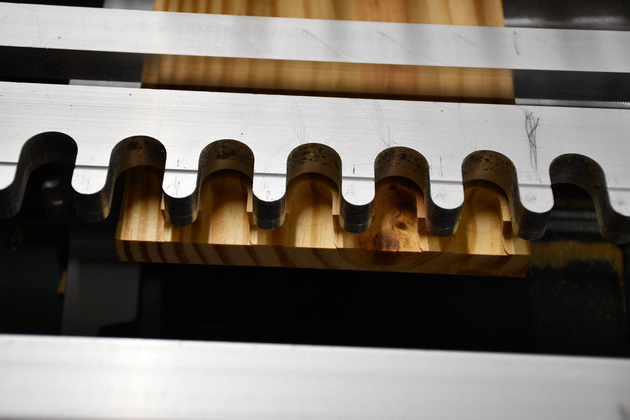

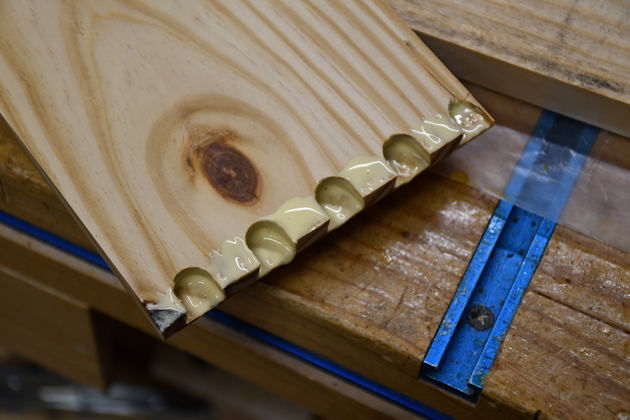

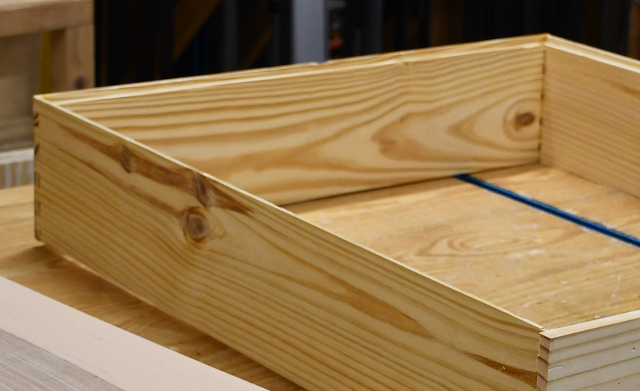

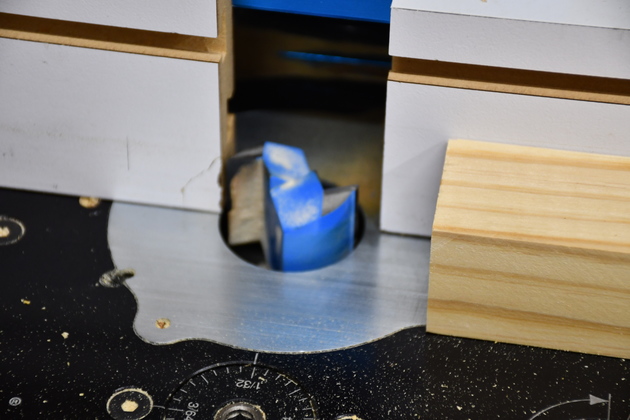

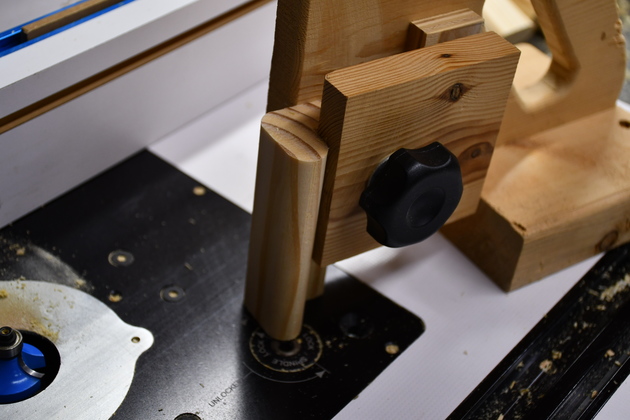

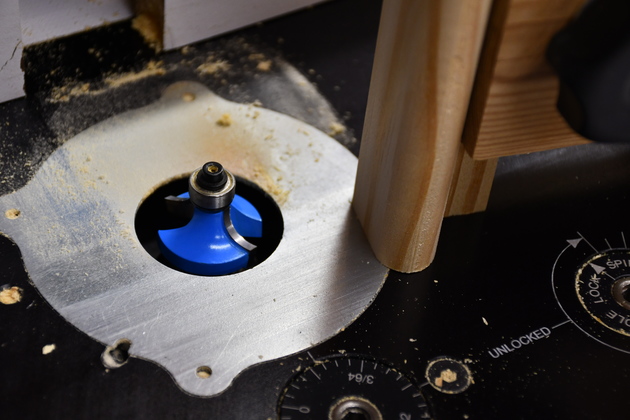

Sizing 2x8s into lumber for the drawer frames. I use the Cut List and cut each piece to the length needed to make the fronts, sides and backs of the drawers. After cutting up these 2x8s I'll resaw them to the correct thickness. Resawing means I get multiple thinner pieces from each 2x8 cut.