| |

|

|

|

|

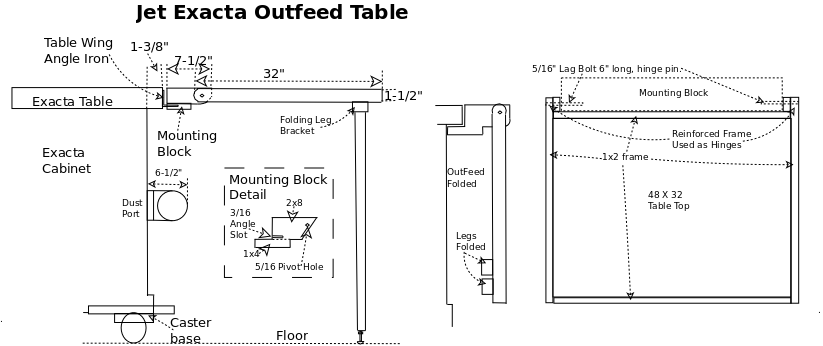

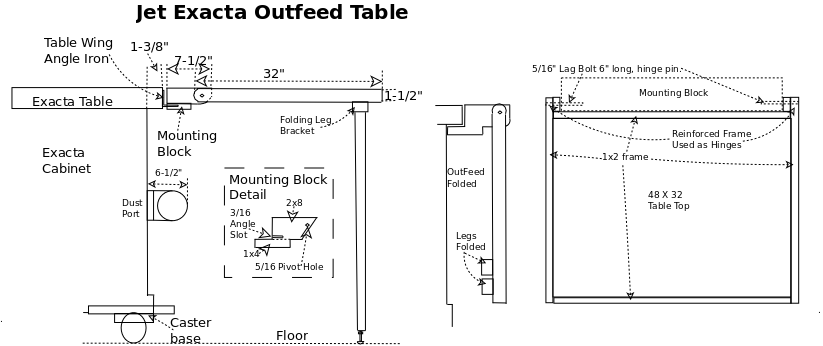

Jet Exacta 30, Outfeed Table

|

05/09/17: Page Origin

I saw a video by April Wilkerson, talking about a drop-down outfeed table for a table saw, and realized that is something I have been needing.

I saw another video by Laney Shaughnessy which had some additional ideas I liked.

Until now I have used a roller stand which helps but is still a pain to use and store.

So I decided to add an outfeed table to my Jet Exacta 30" table saw.

The Exacta has an angle bracket (1-1/2 X 1-1/2) on the back of the table, helping to support the cast iron wings.

I'll use this to attach the mounting block for the outflow table.

I laminated two pieces of 1/2" pine plywood for the table proper, with 1x2 frame around it.

I also laminated 1/2" x 6" wide plywood strips on the bottom side of the table under the two miter bar slots to help reinforce.

The two side 1x2 frame pieces extend an extra 3", with an extra piece laminated the the extensions on either side of the mounting block to make hinges.

|

The mounting block test fit on the back angle bracket where it will be bolted.

|

|

The outflow table test fit.

Its made of two pieces of 1/2" plywood, laminated together then a 1x2 frame

I painted it before mounting.

|

|

Left hinge.

|

|

Table in dropped position, legs aren't mounted yet.

|

|

Dropped table from the back.

|

|

Right hinge, you can see how the mounting block is made, I laminated a 1x4 to the bottom of a 2x8 then slotted it to fit the back angle bracket.

Final install will have 1/4" lag screws up through the rear angle bracket into the wood.

|

|

Table from left front corner, no legs yet.

|

|

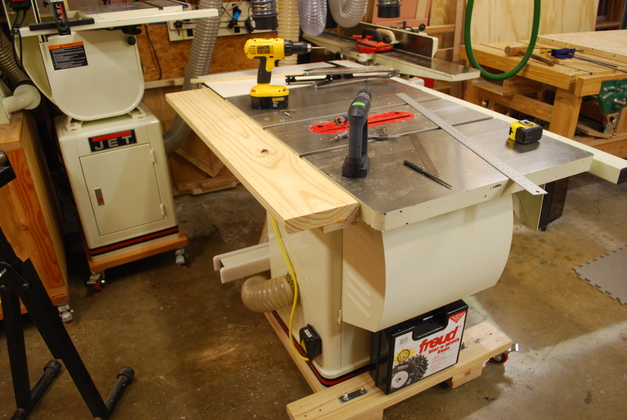

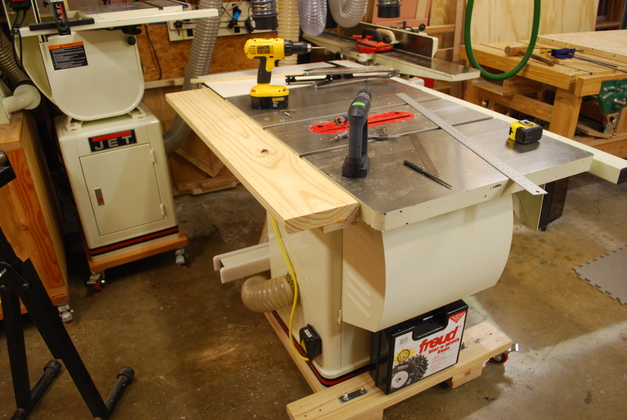

Completed outfeed table hanging on the rear of the table saw and rolled back out of the way.

It fits perfectly.

|

|

Saw rolled out with table extended.

You can see the legs, I laminated a 1x4 to a 2x4 then ripped it to 2-1/4" wide and tapered it slightly using a jointer.

The bottom had 5/16" carriage bolts wit a tee nut as levelers, allows me to adjust for the uneven floor in the garage/shop.

The folding leg brackets came from Rockler, I thought that would be easier to raise and lower than a stiff leg, plus a wooden stiff leg normally compresses over time and isn't very ajdustable.

|

|

Side view of extended table.

Note no miter bar slots routed yet.

|

|

Back side of extended table.

|

|

Routed miter bar extensions, just far enough to clear my cross cut sled.

|

|

Table, dropped as seen from the back.

|

|

As seen from the side, note the legs folded just above the caster base.

You can also see the 4" dust collector port just above the legs.

|

|

Saw with finished outfeed table folded tucked into it's normal hiding place.

|

|

Looking North West, the saw is stowed in it's normal place.

|