|

|

|

|

|

Shop MiniSplit AC

| |||

|

|

|

|

|

Shop MiniSplit AC

| |||

| Back To HeatCool | Unit Info | Old AC Removal | New Unit Arrival |

| Inside Mount | Outside Mount | Power | Flare Nut Torque |

| Torquing | Vacuuming | Finished | Thermostat |

In 2018 the old Samsung AC in the shop died (RIP). I went to Consumer Reports and found the best replacement window AC I could, which turned out to be an LG. I had heard some bad stories about LG but Consumer Reports is a good source for info on these things. The Samsung was a 18000 BTU (1-1/2 Ton) using 240V, the LG was a 12,000 BTU (1 Ton) using 120V. The Samsung lasted about 14 years. The LG's first year I noticed the water coming out the condensation drain was very rusty, leaving rust streaks wherever it ran. This is not a good thing, I don't think this LG is nearly as good as the Samsung. One other note, the LG, being a 12k BTU system doesn't blow as hard as the Samsung, hence I had to use a small fan to circulate the air. In 2019 the plastic condensation connecter had failed and water was leaking straight down on my BBQ grill cover, in addition, the rust in the water was very bad and had stained the grill cover and the cement under it badly. In late 2020, during the Covid-19 pandemic, the LG was still cooling but the rust stains outside had gotten even worse.

In the fall of 2020 and after the 6" DC automation project was complete, I decided to start planning my next shop AC.

Mini split AC appealed to me, and since they cool and heat and are very effecient (20 SEER), I can retire the 57+ year old Dearborn stove, (it still has the original radiants BTW).

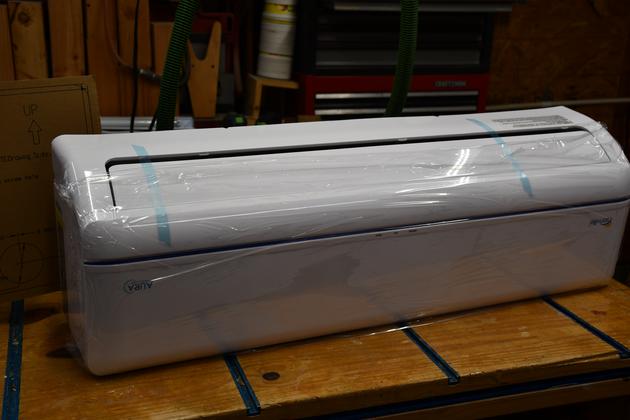

The MrCool 18000 BTU DIY (A-18-HP-230B) caught my eye, but after reading a lot of customer feedback about bad customer support on Amazon, I searched and found the Senville 18000 BTU.

It has a 20 SEER rating, it costs about $1200, but it is not quite DIY, but easily done, with a little experience, a vacuum pump, and a vacuum guage.

I found a pretty good video on YouTube.com by Doublewide6 about install this exact AC.

The Senville comes with the refrigerant line set, the charge is in the outside unit so you need to connect the lines and vacuum down the system before opening the charged line.

The MiniSplit is a Senville Aura series, model: SENA/18HF/OZ.

A lot of mini splits use wireless and can be controlled by a smart phone, but, since I'm not a fan of smart phones (worked in network security 10 years) I'm thinking the hand remote should be sufficient.

Although, there are a few compatible WiFi thermostats that allow remote control of a minisplit via a desktop.

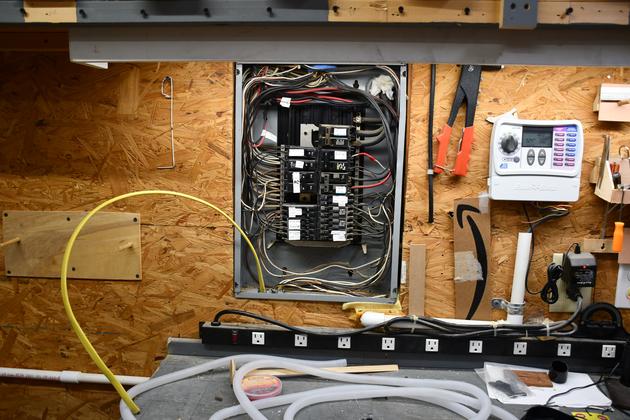

The old Samsung 18000 BTU AC had required 240V AC at 20Amps which I then rewired for 120V @ 20Amps, for the LG, so I'll need to return to the 240V circuit but it won't have plug inside, it'll be wired directly into the disconnect outside.

The only electrical problems I have had in this house, the former owner was a telephone repairman, and used gobs of black plastic electrical tape (no wire nuts) and used 12 AWG wire on 15 Amp. circuits.

I'm not an professional electrician, just a homeowner, but, long long ago in a galaxy far away, I was an electical engineer and understand the National Electrical Code, and intend to obey it.

The Senville needs 240V single phase AC at 20Amps, all power is fed to the ouside unit which, in turn, feeds the inside unit.

I'll need to set a disconnect outside and run 20Amp 240Volt power to it from the breaker box which is on the other side of this same wall.

Since the circuit is single phase 240V @ 20 Amps, I ran it with 12-2 with ground, so I'll mark the white wire with red tape on both ends.

Most folks houses are supplied with two phases of 120 Volt AC, but the two phases are 180° out of phase so if you measure between the two phases you see 240 Volts, this is what appliances refer to as single (or split) phase 240 Volt.

BTW, 240V single phase means I don't need a return line (but I'll run one in case something changes in the future), just the two individual 120V phases with ground.

Most modern full house ACs need at least 30Amps, but this mini split only needs a 20 Amp circuit so I to got a larger disconnect than I needed and put 20A fuses in it.

I bought a Siemens WF2030 30 - 60 Amp disconnect, wall mount box, and when it arrived, I determined it used Femule (??) 15mm x 50mm cartridge fuses, so I ordered two 20 Amp 250Volt fuses for it.

I also needed a weather proof "whip" to carry power from the disconnect to the outside unit.

I also ordered an outside unit support, a plastic cover set for the lines, and NylogBlue flare sealer.

It works!

After having a mishap when I opened the valve on the outside unit to let R410a into the system, the lineset's flare nut on the liquid line behind the inside unit, blew off, thus I lost all Puron.

I had to get a HVAC tech to charge the system and now it works perfectly.

BTW, this thing is interesting to watch while it works, it frequently makes changes in the large deflector door on the lower side of the air handler, and of course it changes air speed.

|

Outside unit, unboxed in our den. |

|

Line set box contents. You can see the drain hose and interconnect cord(left), line set (right) |

|

Inside unit unboxed, note it is upside down. |

|

The inside unit mounting plate template. Also note the outside unit support, folded up on the bench. And the old AC behind the template. |

|

Inside unit back plate attached to the inside unit panel. |

|

These end supports for each end of the inside unit panel, note the 20° sawed bevels. |

|

I have attached the end supports (Red Cirlces) for the inside unit panel. |

|

Inside unit panel and plate mounted. You can see the slight angle (20°). I still need to cut a hole in the panel for the lineset, cable, and drain. |

|

Inside unit installed. |

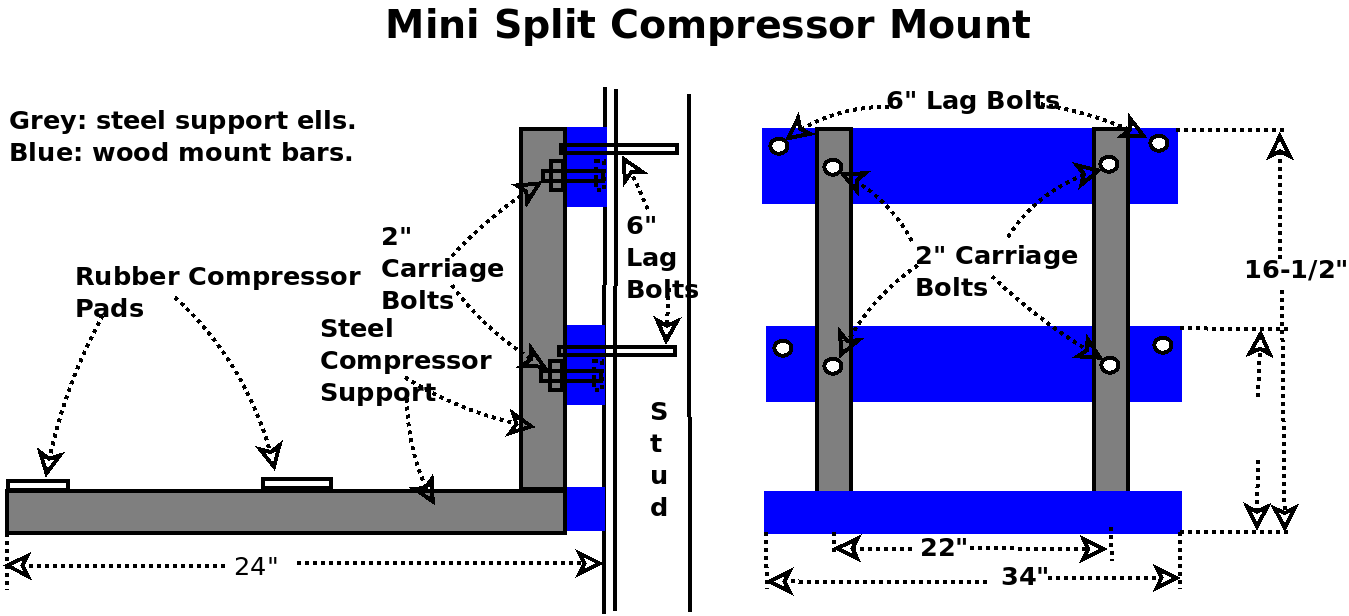

I will attach the horizontal support bars to the studs in the walls with 6" lag screws. The horizontal support bars will have 3/8" carriage bolts sticking out. Attach the steel support Ells to the 3/8" carriage bolts protruding from the horizontal support bars.

|

outside unit support bars, painted several coats since its going outside, you can see the 3/8" holes near each end. Note the 2 ell shaped steel outside unit supports, upper right. |

|

Back of outside unit support bars, note the counter sunk holes for 3/8" carriage bolt heads. Closer look at steel support ells. |

|

Outside unit up on support trestles. Raising it 12" makes it easire to lift, remember it needs to rise 50". Most of this thing's weight is concentrated on the right end (Where the outside unit is, I'm guessing). |

|

Close look at the outside unit's foot on top of two support trestles. |

|

Outside unit in it's new home. Note the Disconnect to the left and it's whip circling around to the right side of the outside unit. I had to have help getting it up this high. |

|

A little closer look, note the disconnect on it's left. |

|

Right end of outside unit, refrigerant lines are next. |

|

Note rubber mounting pads under outside unit mounting foot. The hex bolts are 5/16" with washers on both sides. The mount came with 8mm hex bolts and very thin (skimpy) flat washers. |

|

Breaker panel open with 12-3 w GND (yellow) sticking up from the bottom. |

|

Breaker panel cover replaced, breakers are open. |

|

The disconnect. |

|

This is the disconnect block with two 20Amp fuses. |

|

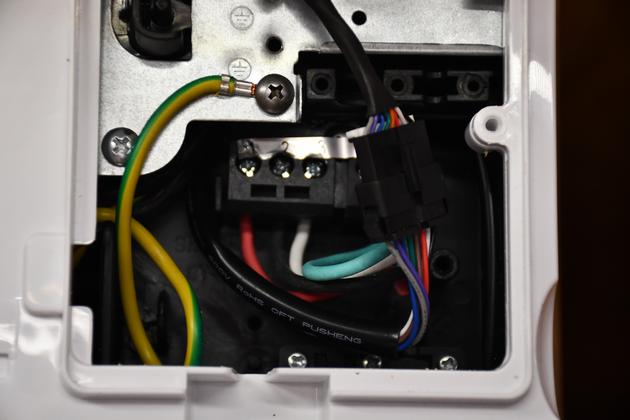

Inside unit cable connections. Note: Red is 1, Blk is 2, and Wt is 3. You can see the green wire (ground) but not where it is connected, green, by National Electrical Code is always ground. |

|

Outside unit with refrigerant connection cover removed. |

|

Both my torque wrenches, 1/2" drive upper, 3/8" drive lower, with the flare nut crowfoot wrenches. |

|

I set the torque wrench at 10 ftLb, pulled down on the scale's handle till it clicked. I pulled several times getting 8.5 - 8.75 Lbs averaged 8.6. 1.1666 X 8.6 = 10.03 ftLbs. |

|

Line set cover showing drain exiting at elbow. |

|

Line set cover is not against the wall since I had to clear the outside unit ell mounts. |

|

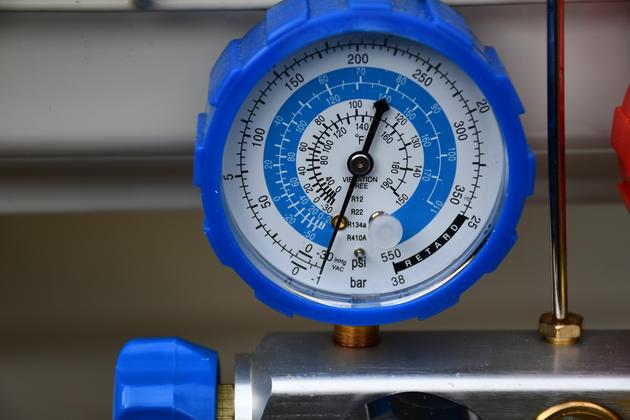

Vacuum setup, yellow line from vacuum pump to manifold, blue line from manifold to gas return connector on outside unit. |

|

Vacuuming complete, yellow knob (to vac pump) closed, blue knob still open (I'm seeing the system's pressure), low pressure valve showing -30psi vacuum. Now I'll wait awhile to see if it holds. |

This thing works great!!! Its a little strange to watch it work, it ocassionally moves the outlet door (at bottom of unit) up and down to distribute the air better. When it cools, it cools the room a little lower than the setting, then allows the room to come to the set temp and keeps it there.

|

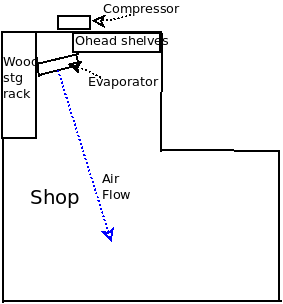

Shop small East corner. |

|

Taller look at NE nook, with new mini split near the ceiling, and new storage shelves below it. Betty said this looked extremely compact (crowded), but I can access everything fairly easily.. |

|

Looking straight East, into the nook. |

|

|