|

|

|

|

|

Dust Collector Automation Electronics

| |||

|

|

|

|

|

Dust Collector Automation Electronics

| |||

| AnaMux | Servos | Diagram | System cabinet |

| PCB | Isnsr | Sketch | Data Terminal |

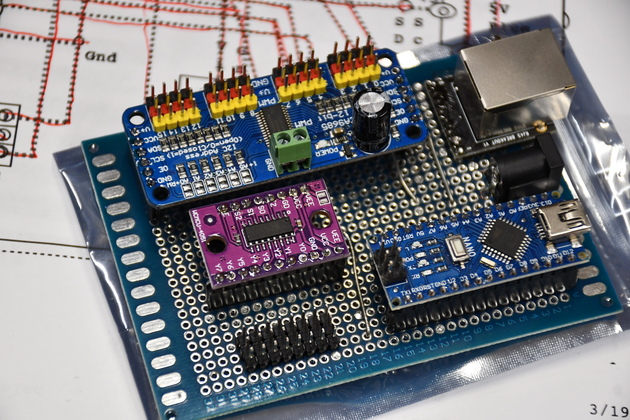

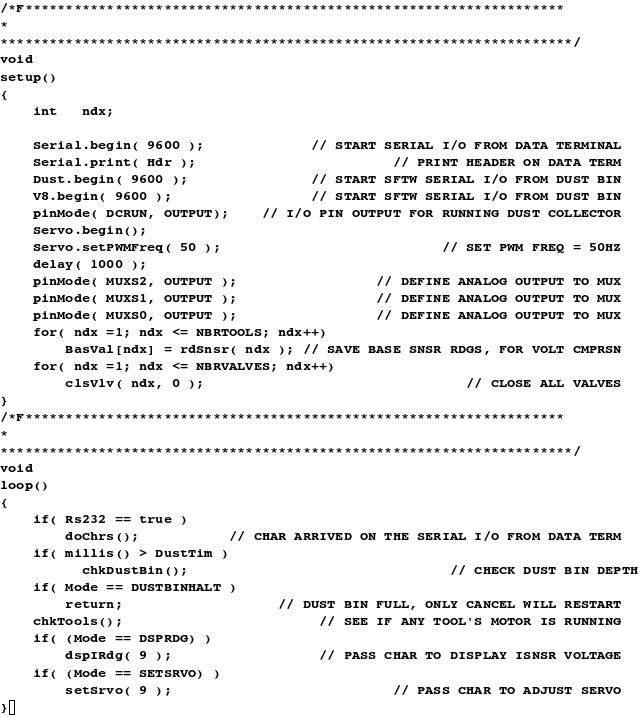

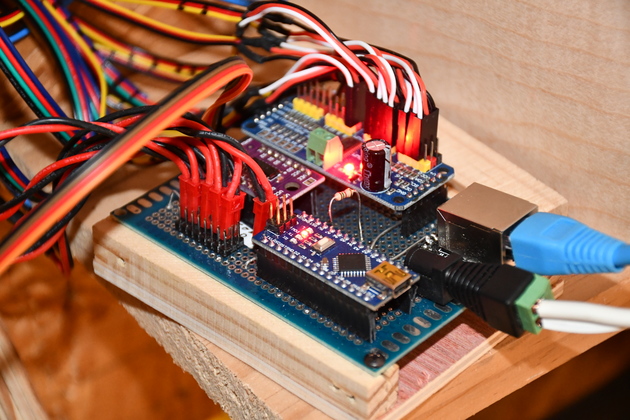

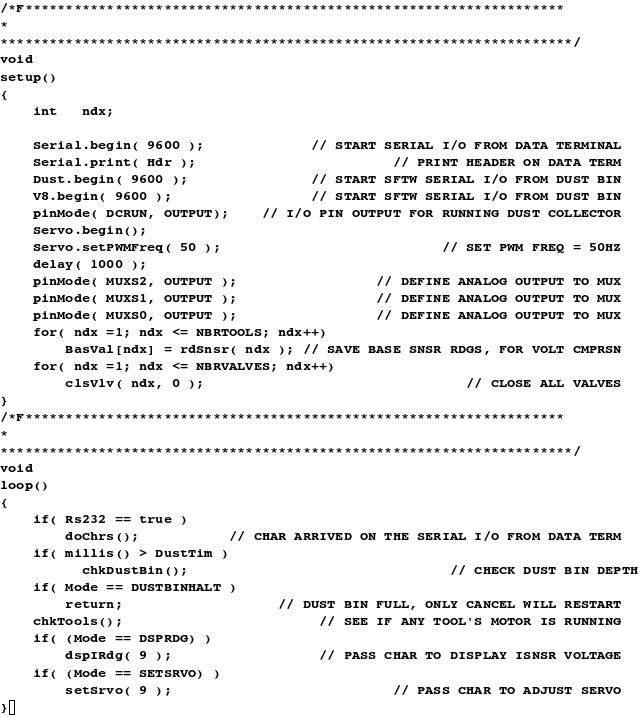

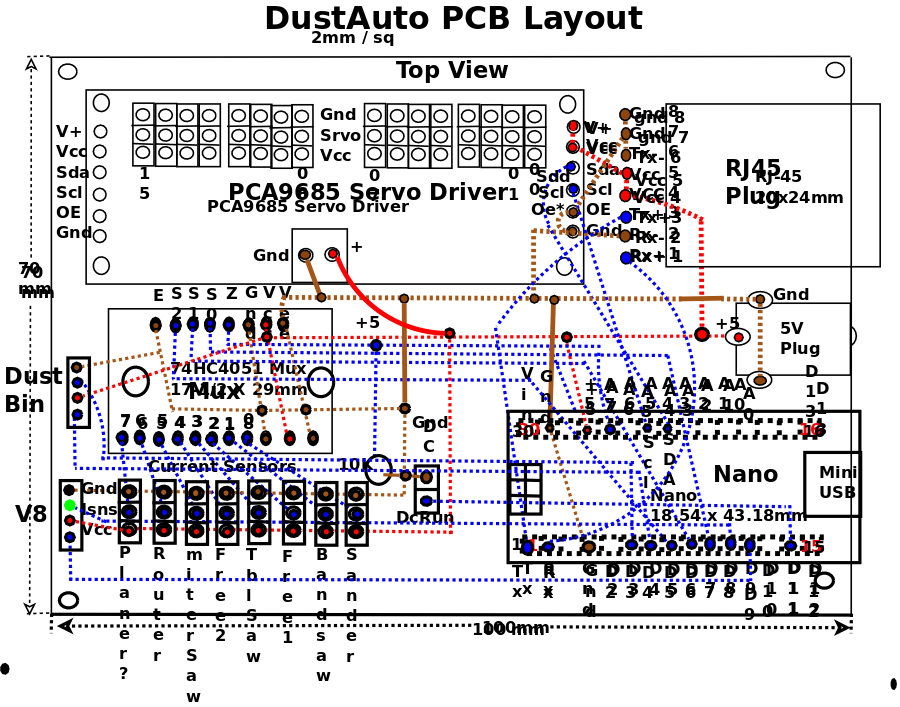

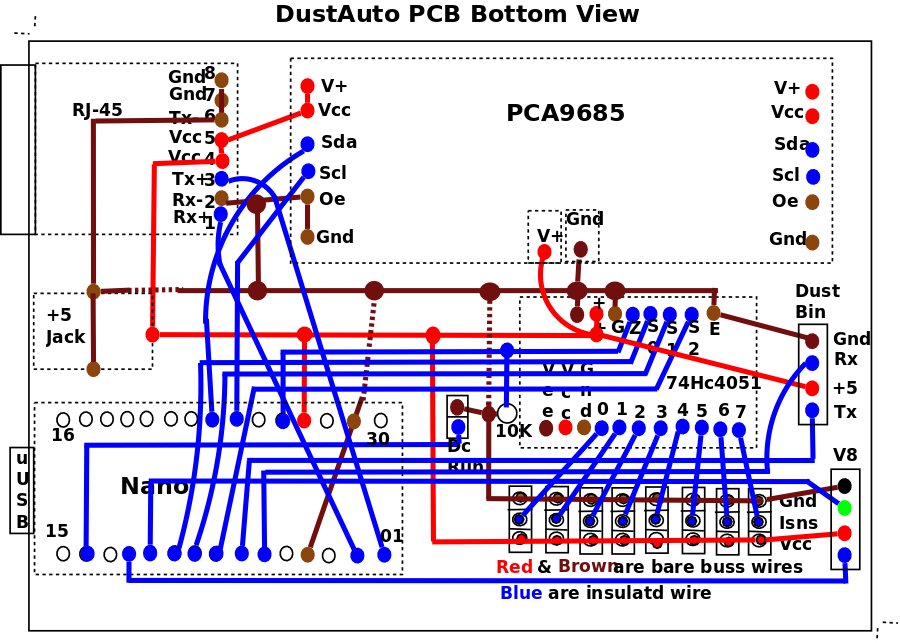

There are probably many better ways to do this, but I'm old school and am comfortable with building things on perf board.

I'll use the same approach to layout as I did with the data terminal, that

is, use a breadboard (copper clad perfboard with holes on .1" centers).

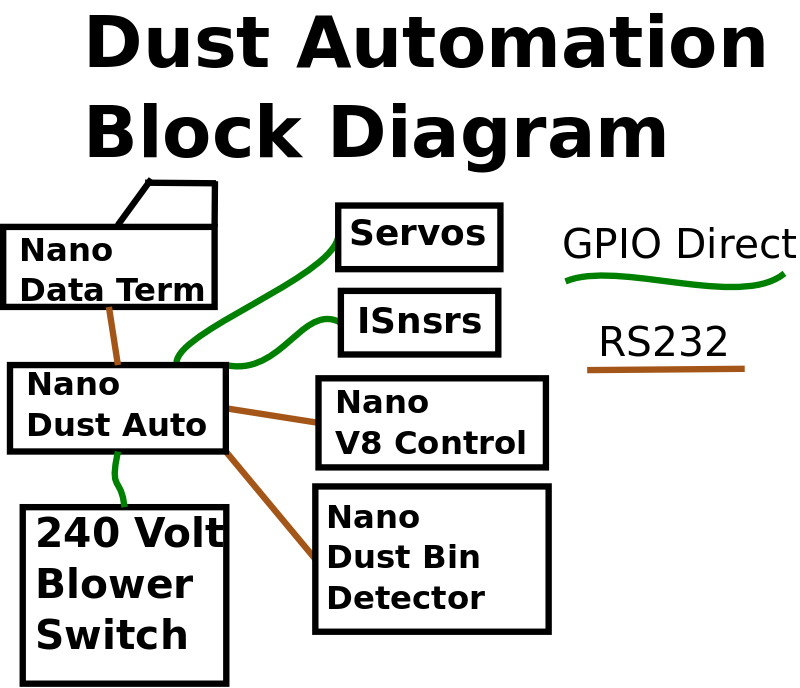

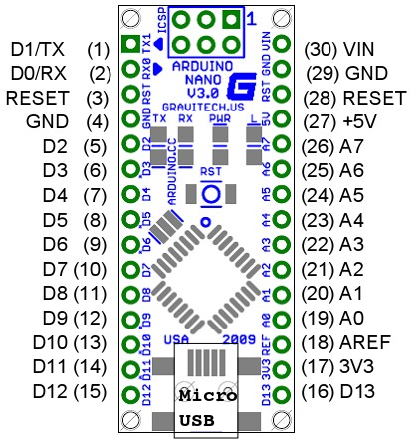

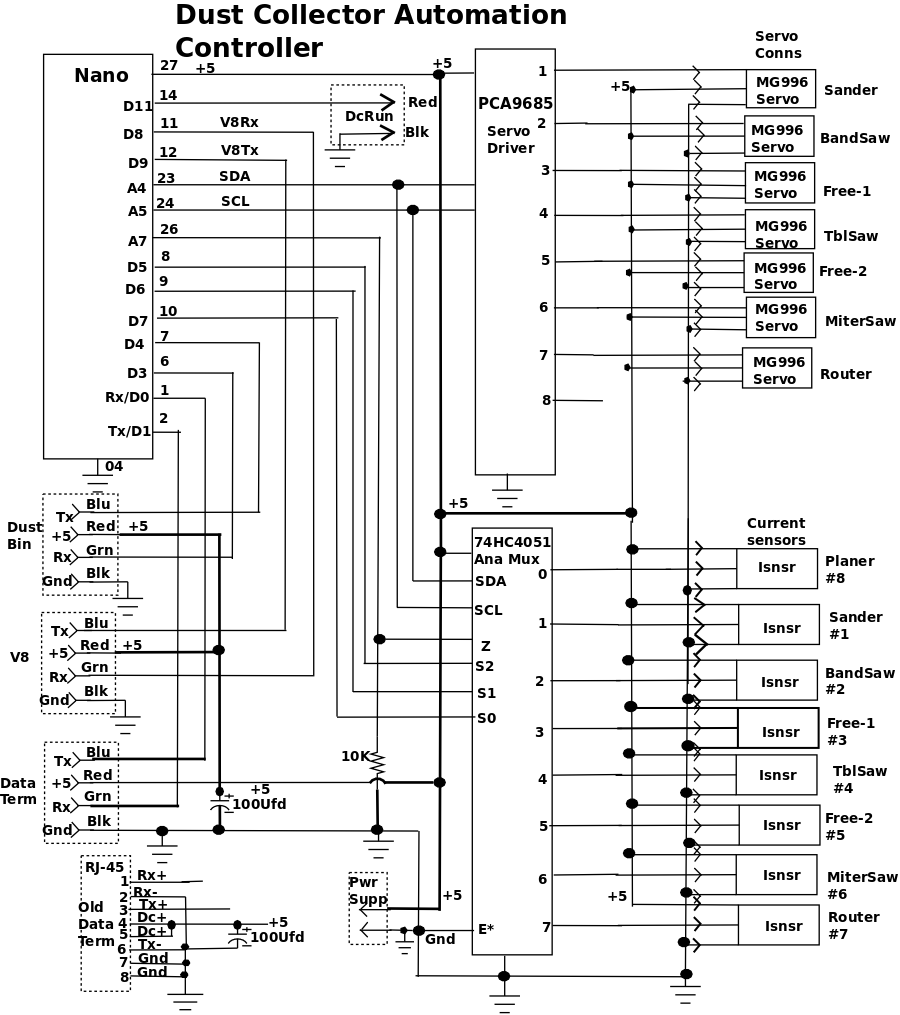

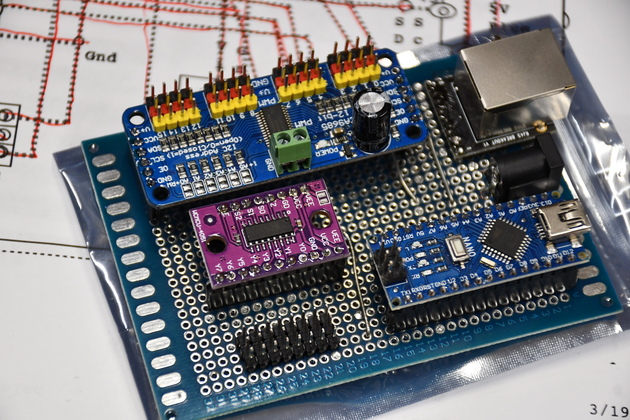

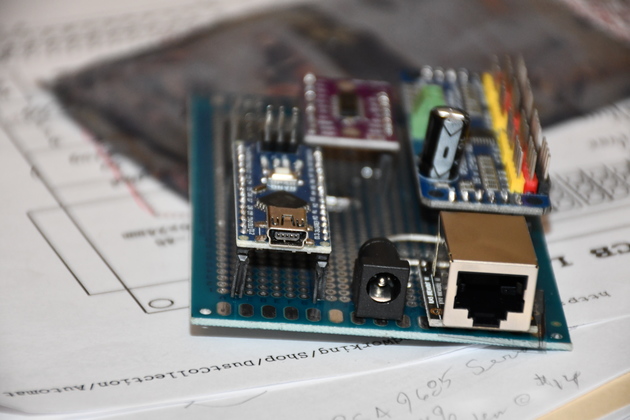

Also similarly, this PCB will have only 3 active electronic components,

nano, analog mux, and servo driver, plus lots of connector pins.

There will also be 8 places to plug in current sensors from the various

machines in front of the analog mux.

Isnsr 8 will be plugged into the sensor 0 position, the software will

accomodate this by throwing away the 8 bit when addressing the mux.

Think of it like a truncation.

There will also be a RJ-45 for the data terminal, and a 5.5mm 5V power

plug.

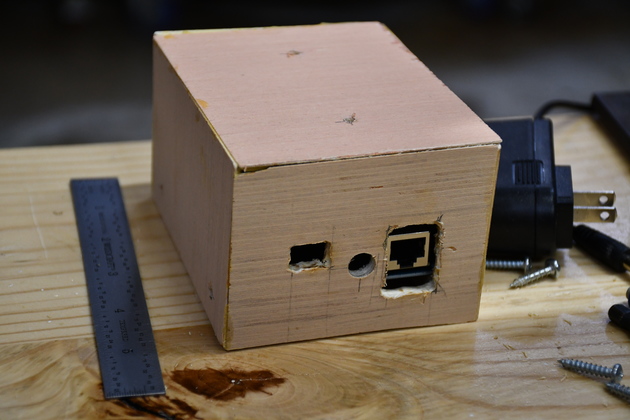

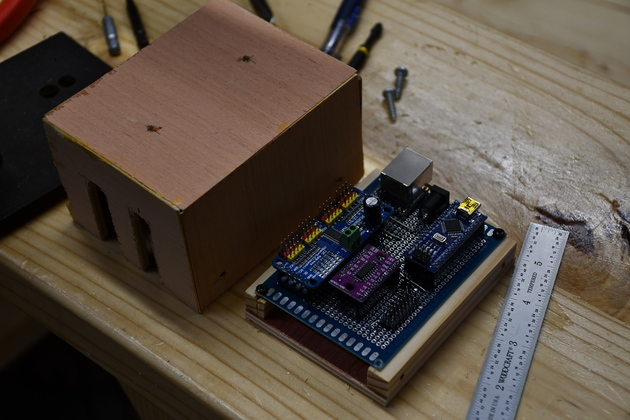

I'll mount the PCB in a small wooden box, probably attached to the ceiling.

PS:

Later I added two 4 pin headers, one for DustDetector2 and one for Valve8.

I'm going to abandon the RJ45 (ethernet cable) and move to a 4 pin JST

connector and 4 pin flat cable, this will reduct the cost and simplify

construction.

Also I'm going to move the Data Terminal's computer PCB from the side to

the

base board to improve access.

The system has 2 missing Isnsrs (the 1 and 2 Free). When I was testing the system, I found that when I had an active Isnsr, and as the analog mux scans across it's inputs (normally from Isnsr's) and found a missing sensor, the system thought the missing Isnsr was hi also, and would open it's valve and turn on the DC. The next scan found the real 'on' I snsr and toggled between the active machine and missing Isnsr. With the oscilloscope on it and discovered the high impedance of the analog input to the Nano, wouldn't discharge the voltage from an active Isnsr, so I had to add a 10K pull down resistor to the Z input.

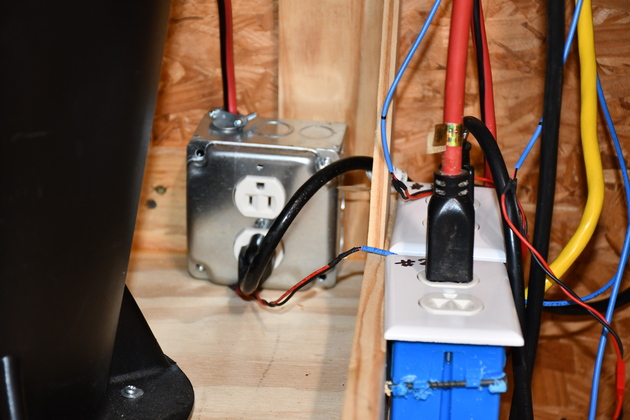

The system runs off the lighting circuit in the shop, its only on when the lights are on. The sysem needs a fair amount of current, so I ended up using a 5Volt 8Amp power supply, 6 Amps would have done it but Amzon didn't have 5Volt 6Amp supply. I tried a 4Amp supply but if I turned the lights off and back on (or a power glitch), the system would crowbar the supply and then went into a kind of oscillation of full voltage then crowbar. I'm guessing the system or the PCA9685 would try to move more than one servo at a time, each servo is capable of drawing a little over an amp. More amps solved the problem.

Click for larger pics |

|

|

|

|

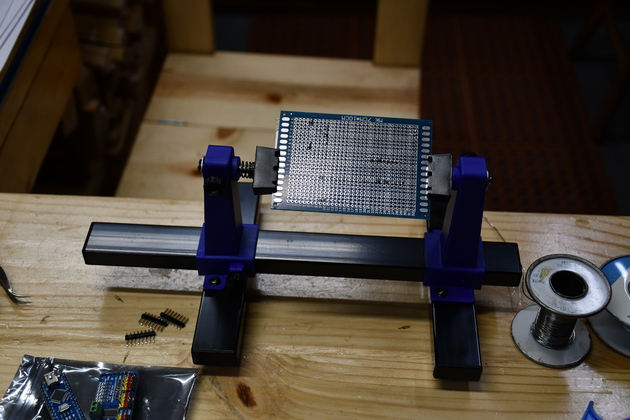

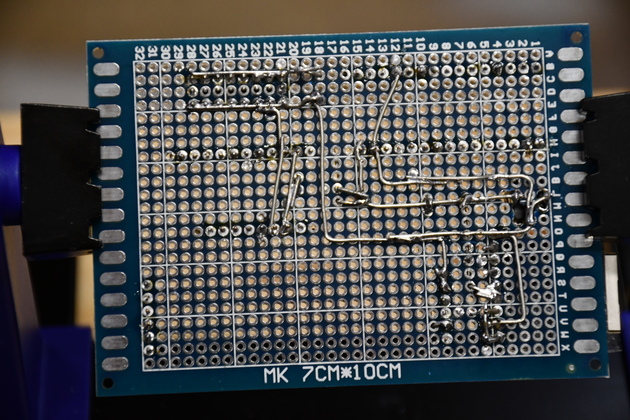

Pcb soldering headers, power, and ground. |

|

Bottom of the board. All headers, power, and ground soldered, ready to connect signals. |

|

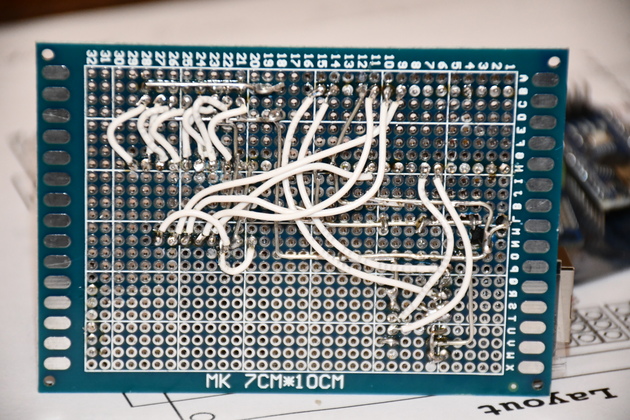

All the signal wires soldered in. |

|

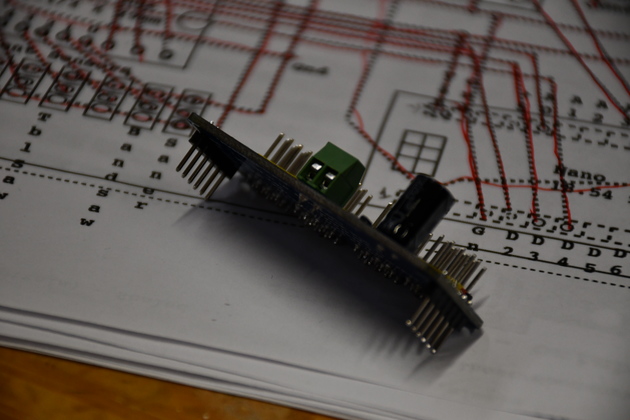

The 16 channel servo driver with new headers pointing down. |

|

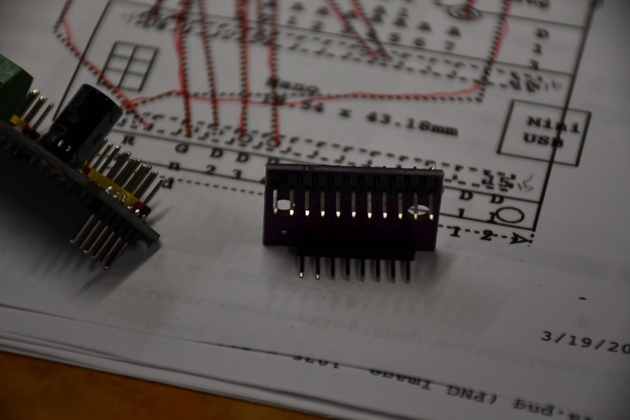

The analog mux with it's headers soldered in. |

|

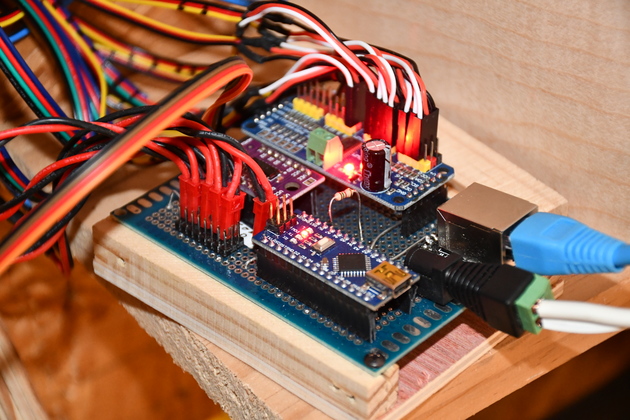

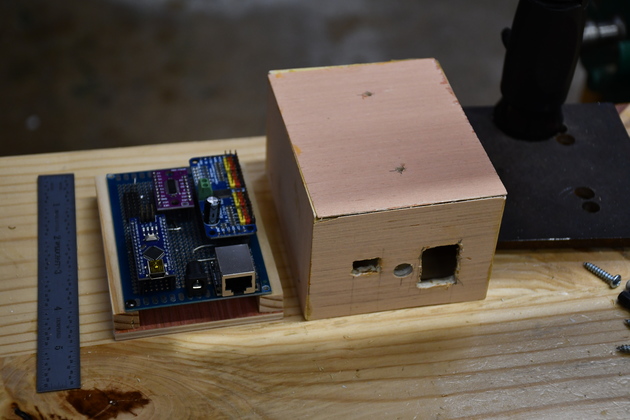

Control board with all components plugged in, ready to test. I haven't added the pins for the Blower's DC on cable. I also haven't added the 10K pull down resistor for the analog input. |

|

Connector end. |

|

Front of system cabinet, again the pink plywood. I know it's ratty looking but it works well. |

|

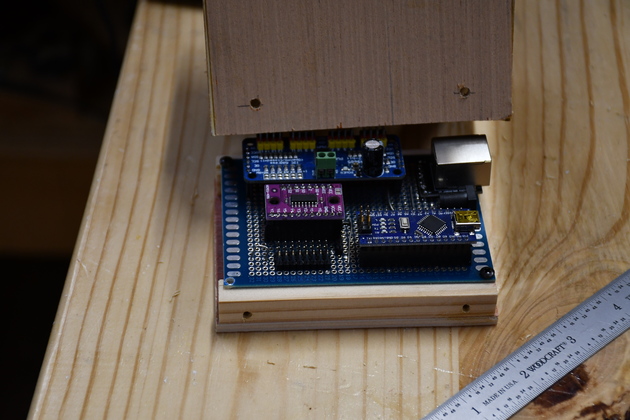

The cabinet's rear beside the system control board on it's base. Note the control board is mounted on the cabinet base. |

|

Cabinet front with the system board mounted on it's base. |

|

You can see the screw holes that fasten the cabiet to the base. |

|

Terminal swiveled right. You get a better look at the swivel. The swivel allows me to be in different parts of the shop and still see whats going on with the dust collection system and make changes. |

|

Sander updraft valve opened by the servo. |

|

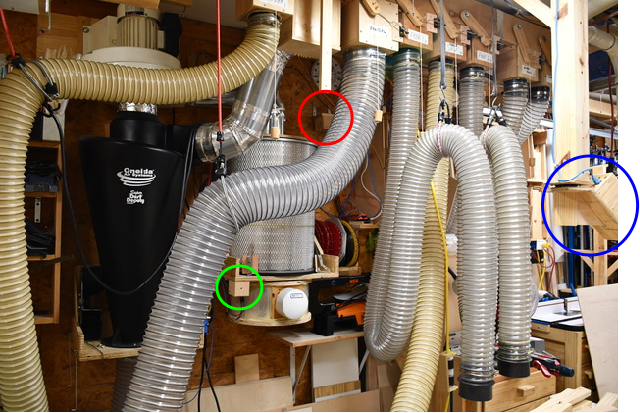

Most of the 6" dust collection system. The DustAuto controller is in the RED circle, the Dust Sensor is in the GREEN circle, and the Data Terminal is in the BLUE circle.

|

|

Better look at the blower switch and two Isensors on the cyclone shelf. The two Isensors are for the sander and bandsaw. |

|

|