|

|

|

Crosscut Sled and Skate

|

01/05/16: Page Origin

I bought a table saw and now I need a crosscut sled.

The purpose of the crosscut sled is to give a nice long and square base to clamp or hold lumber to while crosscutting.

It gives you a nice square cut.

This crosscut sled will be 36" wide by 29" front to back and made of 1/2" oak plywood.

The 29" depth (front to back) is the same as the saw table.

The handles at the front and rear are made of laminated Luan plywood, a total of 1-3/8" thick.

The handles must be high enough (about 5-1/2" high) so I can make cuts with the saw at full height (3") and still hold the two sides of the sled in exact position.

Remember, the sled base will be cut in two pieces and the handles must hold everything in exact position.

The runners will be hardwood, machined to just fit in the two miter slots on the saw's table.

BTW: the background for this page is a pic of the oak plywood sled base.

|

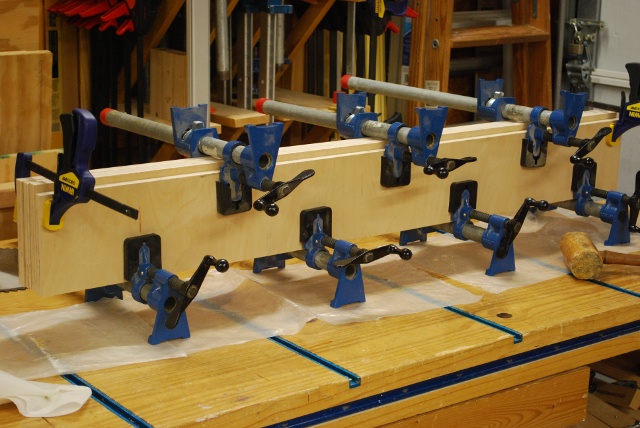

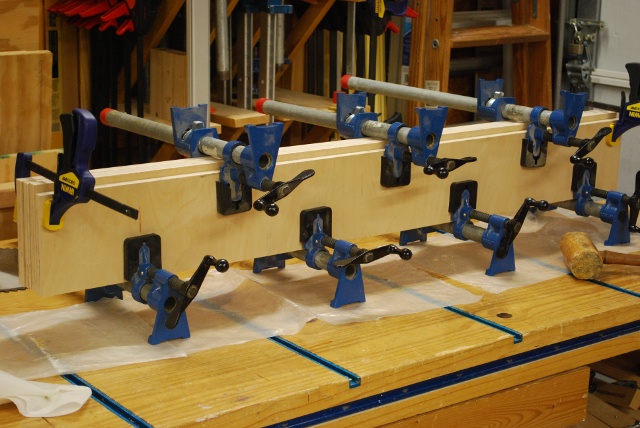

Sled handles being laminated from two pieces of 3/4" Luan Plywood.

|

|

Edge of laminated handle, its about 1-3/8" thick.

|

|

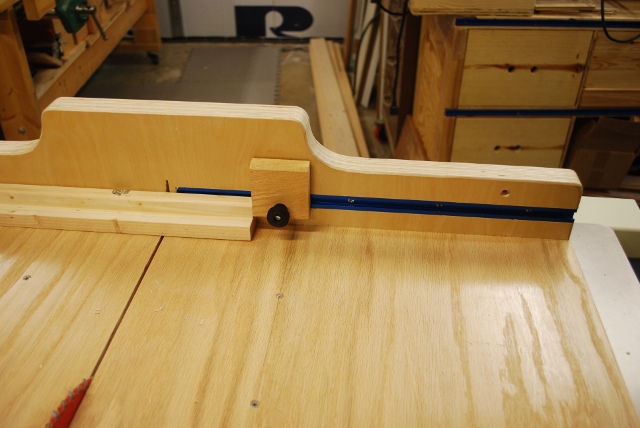

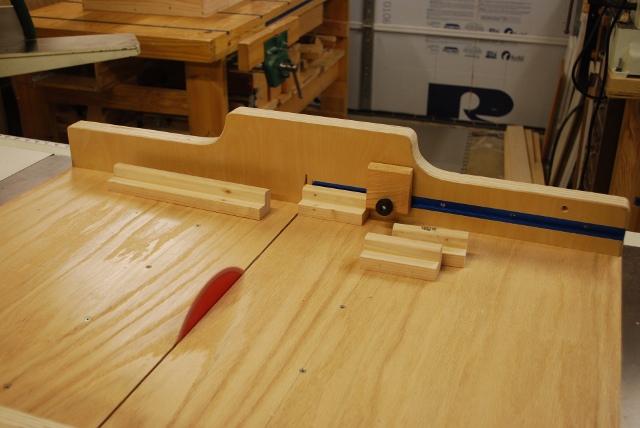

Handle test fit.

|

|

Handle trim marks.

|

|

Front handle trimmed, edged, and sanded.

|

|

Oak runners screwed to bottom of base.

|

|

Edge rounding on handle.

|

|

Underside of sled showing oak runners and flathead screws holding base to handle.

|

|

Closer pic of screws holding base to handle, these are 1-5/8" wallboard screws, countersunk.

This is the back end of the sled, the other end is held on by only two screws until it is adjusted square.

|

|

Sled in saw miters, the blade was raised just enogh to cut through the base and not the handles, yet.

|

|

I'm using the 5 cut method of squaring the front handle.

The back handle is securely screwed to the base, the front handle is only held by two screws, one on each end.

I cut a narrow strip from the edge of a piece of scrap plywood, rotating clockwise to the next cut is referenced to the previous cut.

The fifth cut I measure the width of the strip at the front and back, subtract and divide by 4 to get a single error.

|

|

The fifth strip was wider on the back than the front so the right side of the handle should go forward.

I clamped a block to the base at the right end of the handle and used a field guage to set it the Error Distance from the handle.

Error Distance: fifth strip width at back minus width at front divided by 4.

I remove the screw on this end of the handle (underneath the base), moved the handle to the block, then rescrewed the base using a different hole.

I repeated this until the error was very small (usually a couple of cycles).

|

|

Front of sled, ready to cut a kerf through both ends.

|

|

Cross cutting with the new saw, sled, and skate.

This board was 10 Ft. long when I started.

|

|

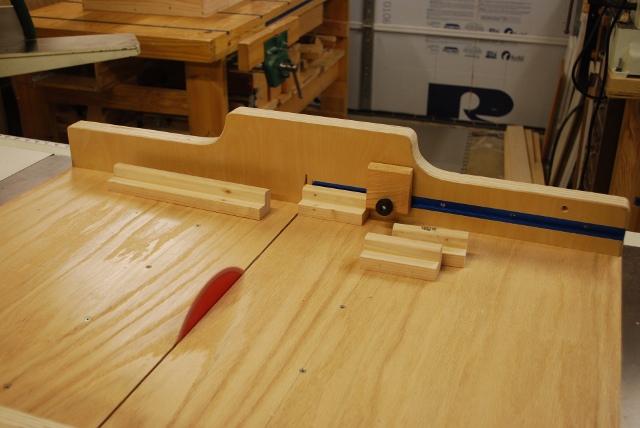

Stop block clampted to front handle.

|

|

View from foot of board being sized.

This board was 10 Ft. long when I started cutting 7" pieces from the end for paper towel holders.

|

|

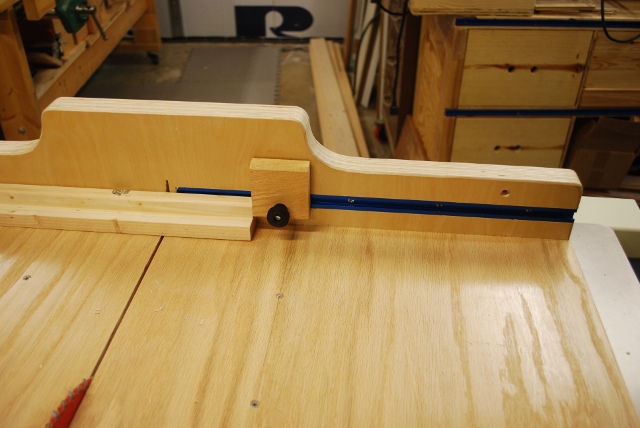

BTW, I also added a tee track to the sled's front for cutting shorter pieces using stop blocks

.

Also please see the crosscut sled extension page.

|

|

Here I'm cutting 4" pieces for drawer pulls from a strip I've already ranneted and rounded.

|