|

|

|

|

Guide Slot Jig

|

06/16/15: Note about using my box joint jig as a slot cutter.

11/15/12: Page Origin.

I like to make racks to hold some tool/parts that have slots for the parts.

You can use a table saw, Radial Arm Saw, router table, or a lot of other things, but I use a router table jig I made.

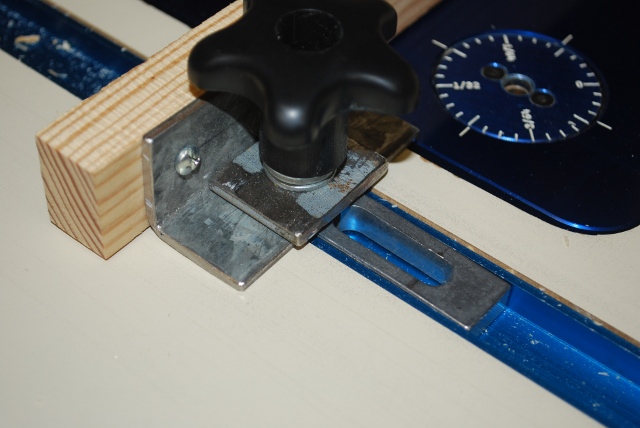

The jig consists of a 1x board and two metal fittings, the rear has a tee nut for the router table fence's tee tack and the other end has a miter bar insert that tightens up.

Each time I change it's setting I use a Square cut block I also use for pushing pieces through.

I can cut slots into stock at any spacing on fairly long boards by cutting from both ends.

I pushed the router table fence back as far as it would practicaly go then set the length of the jig.

Note when I cut a slot most of the chips go to the router table's dust port, the rest go into the router motor box which has a dust port also.

Here are some Pics of the jig and how I use it.

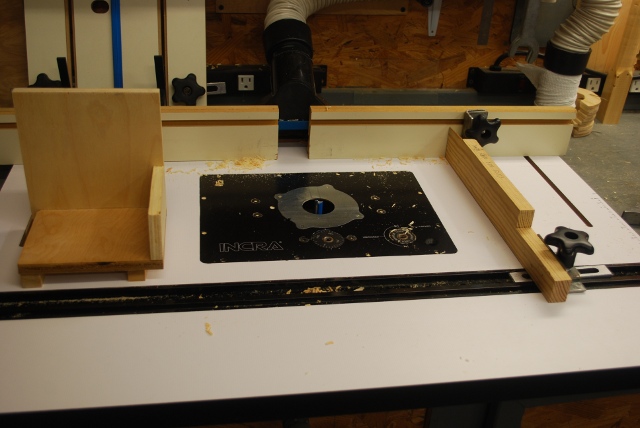

Slots may also be cut with the Incra Precision Positioner I built for making box joints.

After I built the box joint jig, I realized it would also cut slots, so!

I have recently started using the jig with the Incra Precision Positioner I built for box joints as a slot cutting jig.

The same things I need for box joints I need for guide slots.

The only limitation is the box joint jig doesn't have the range of the slot jig so I still use it on some jobs.

|

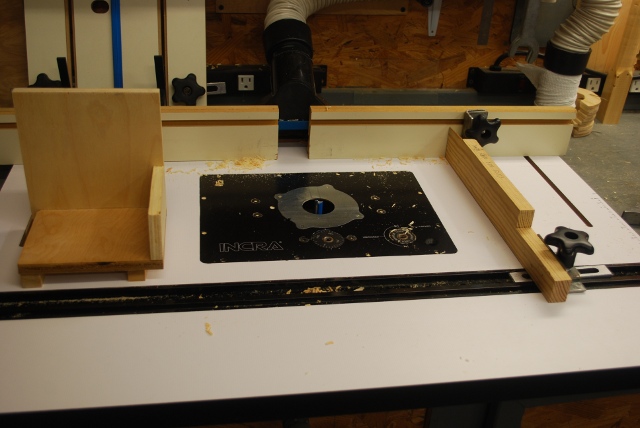

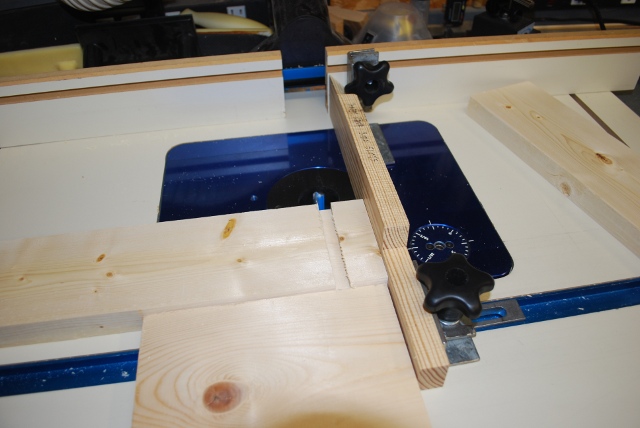

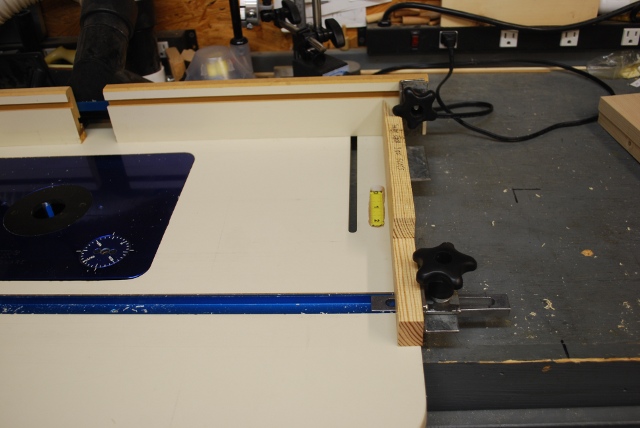

This is my slot jig being aligned on the old router table, it is made from a narrow wooden fence with metal brackets on each end that attach to the router table's fence's tee track and the miter slot on the other end.

The board in front of the dust port is a 1x6" used to align the jig then push pieces through the cut.

|

|

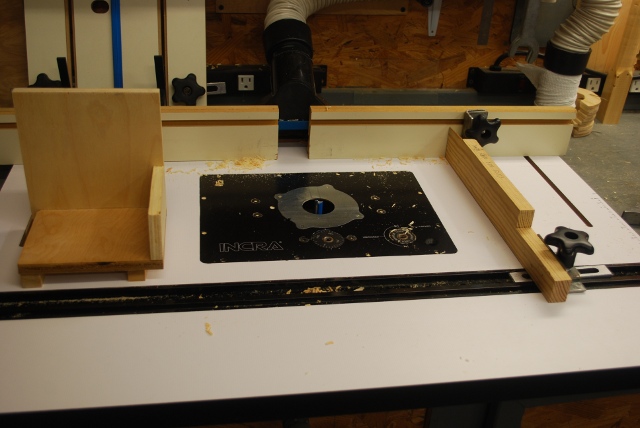

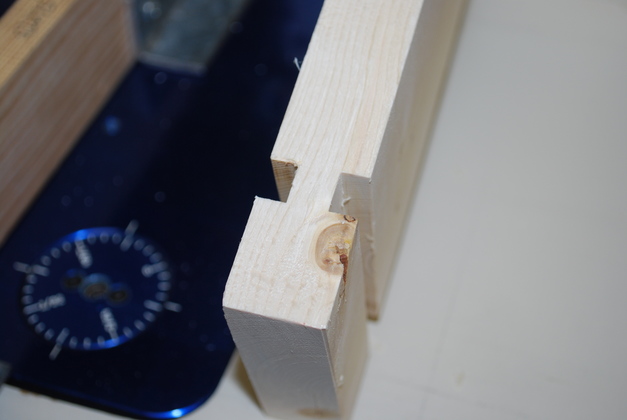

Back side of the fence (tee track) end.

|

|

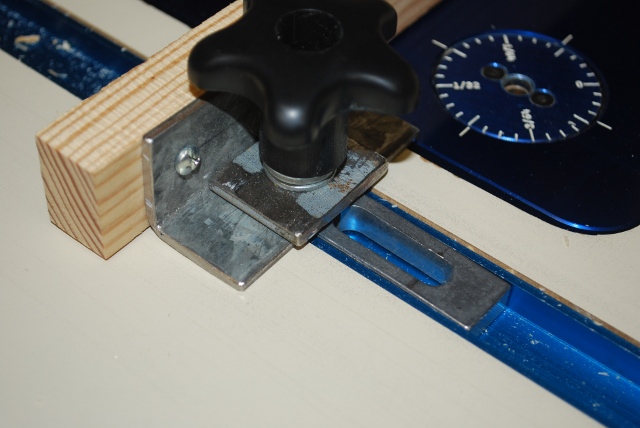

The miter bar end.

|

|

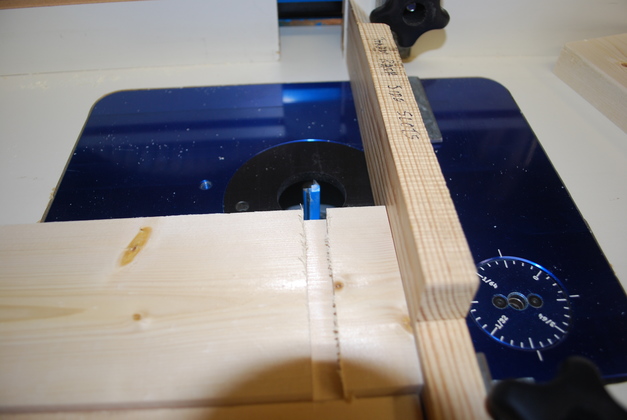

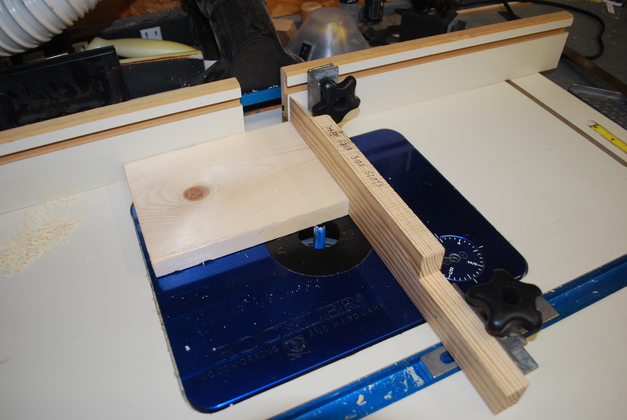

Heres how I push a piece through, as you can see this piece will have a slot on both sides.

I keep a little pressure against the work piece with my left hand and push the piece through with my right hand on the push board.

You set it up for the distance from one end to the slot, then cut all pieces, change the setup and run all pieces through again, cutting a second slot.

|

|

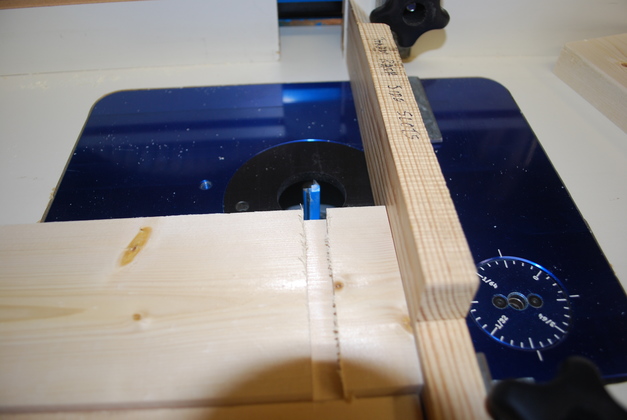

A closer look at pushing a piece through.

Note how the slight left hand pressure keeps the work piece up against the fence on the right side.

|

|

I have recently started using the jig with the Incra Precision Positioner I built for box joints as a slot cutting jig.

The same things I need for box joints I need for guide slots.

Also notice the new router table and lift.

|

|

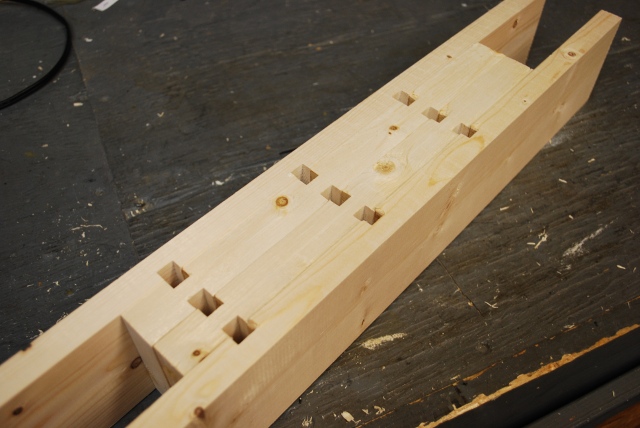

You can see some Die Plate Rack frame pieces with slots cut on the right.

|

|

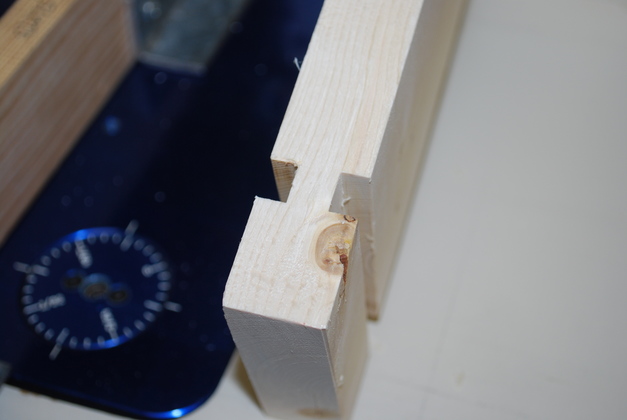

Different view of same piece.

|

|

This little pencil mark on the slot cutter jig fence shows me where to stop the push board.

The piece on the left is being slotted on both sides, note it is thicker than the push board.

|

|

Here I am set up to cut a slot 14 7/8" from the end of the piece, about as long as I can go with this router table.

You can cut slots from both ends which doubles the height of a rack you can build with this, but you do have to change the way you set up the cut (reference from the top of the cut instead of the bottom).

|

|

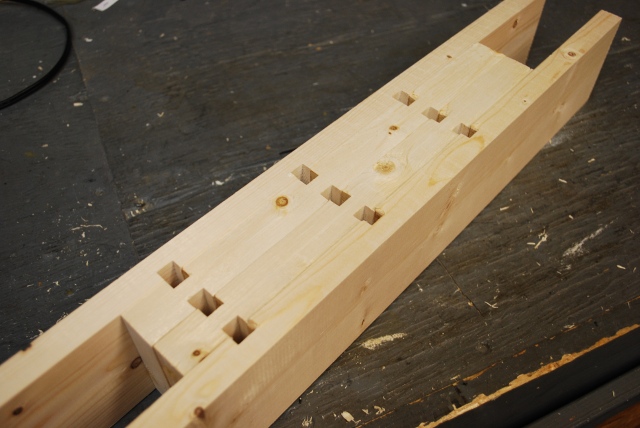

3 column rack guides slotted, bottom of rack on right.

Note how the slots line up, this took setups for both lengths since the two center pieces are shorter than the other two pieces, hence the slots were different distances from the bottom of each length piece.

|

|

Here are all four pieces matched up showing the match up of slots.

The center pieces are 1" thick where the sides are 3/4" (standard 1X4s).

Here is the finished product.

|