|

|

|

|

|

Nano Mount

| |||

|

|

|

|

|

Nano Mount

| |||

| Dust Collector Automation | Dust Detector | Environment Server | Dust Detector Mount |

| Dust Auto | Mini Cauls | Nano 485 Gateway |

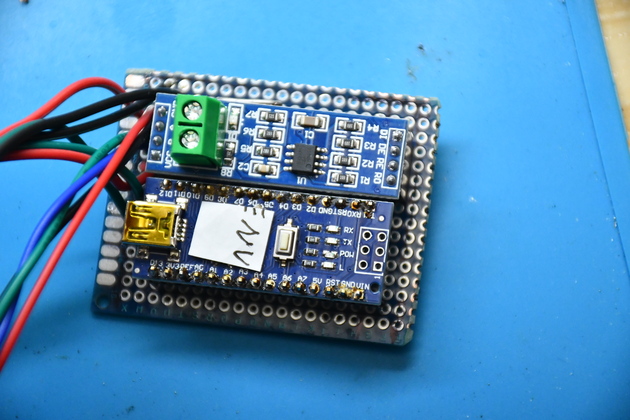

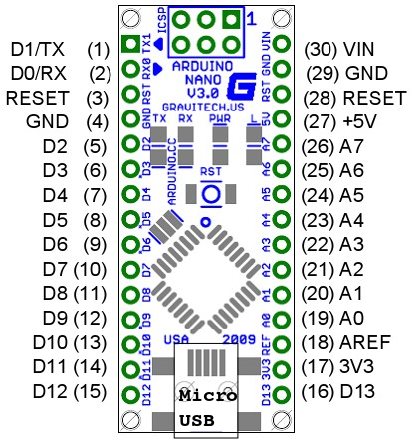

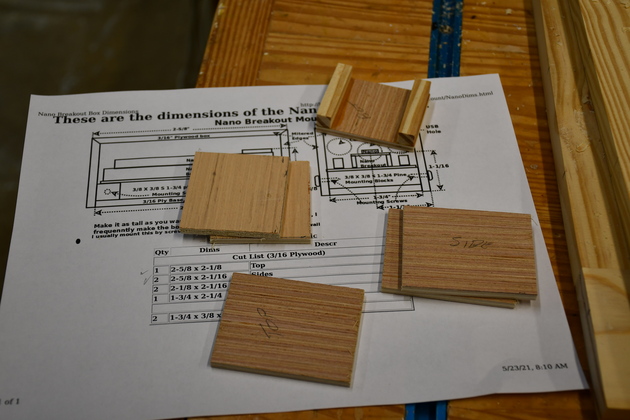

I have been using a number of Arduino Nanos in shop projects and mounted on Nano Breakout boards.

Most of the time I build a small box to house the Nano

and it's

breakout board,

and I've built enough of them now, I decided it needed it's own page.

There are two in the DustCollection Automation project.

One in the Shop Environment project.

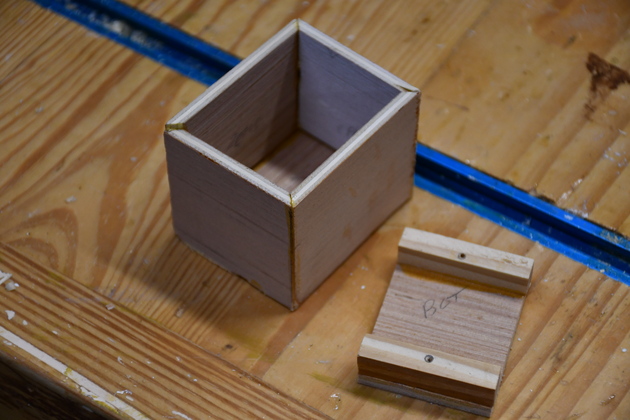

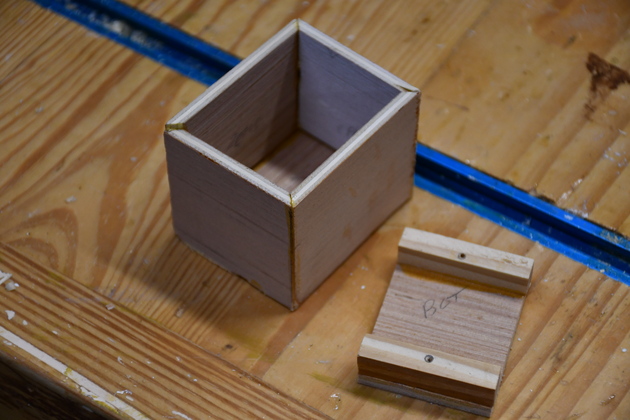

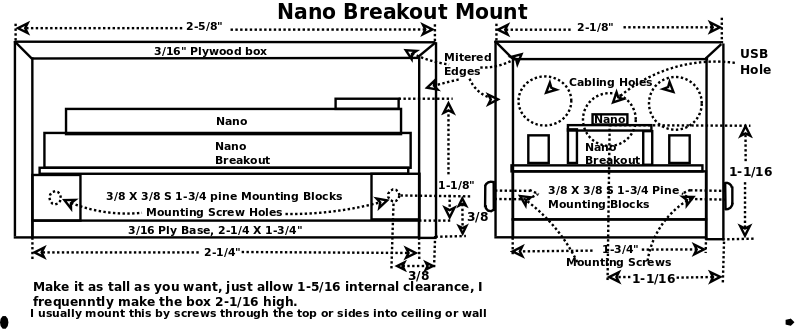

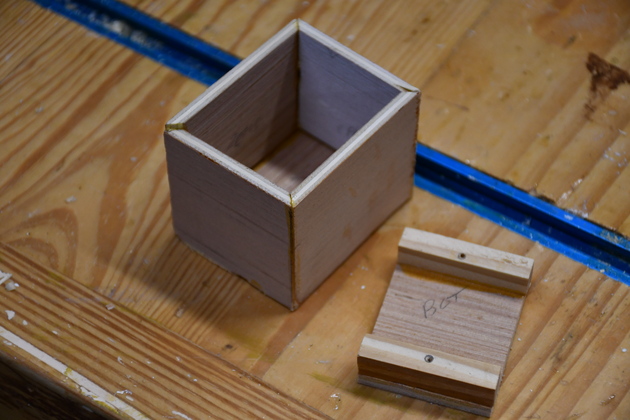

I build these out of 3/16" plywood (Underlayment), with mitered corners.

Miter all edges except the bottom edge.

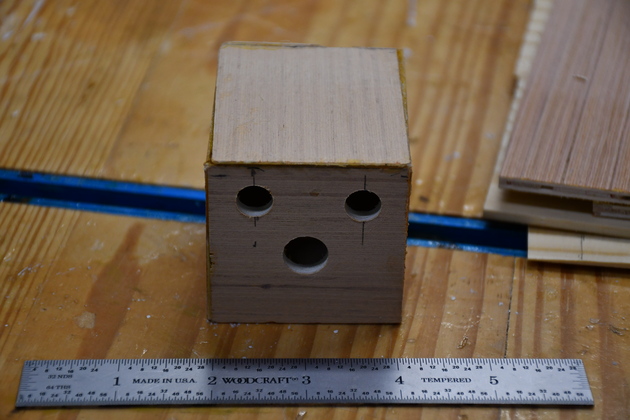

I drill holes in one end for cables and a 1/2" hole for the mini-USB in case you need to change the sketch.

End holes also allow a little convection air to move through the box, reduces heating.

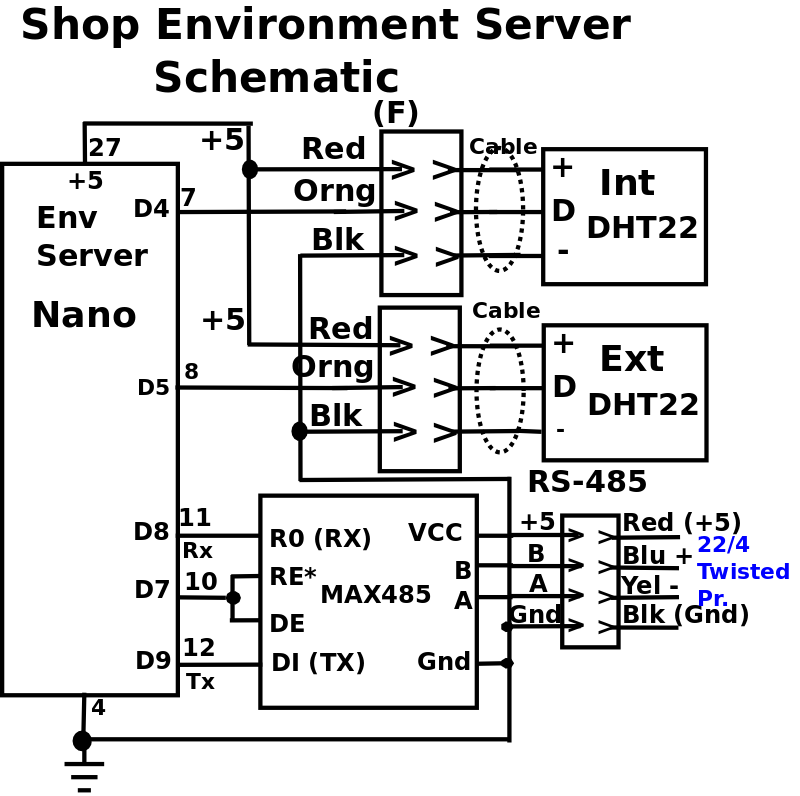

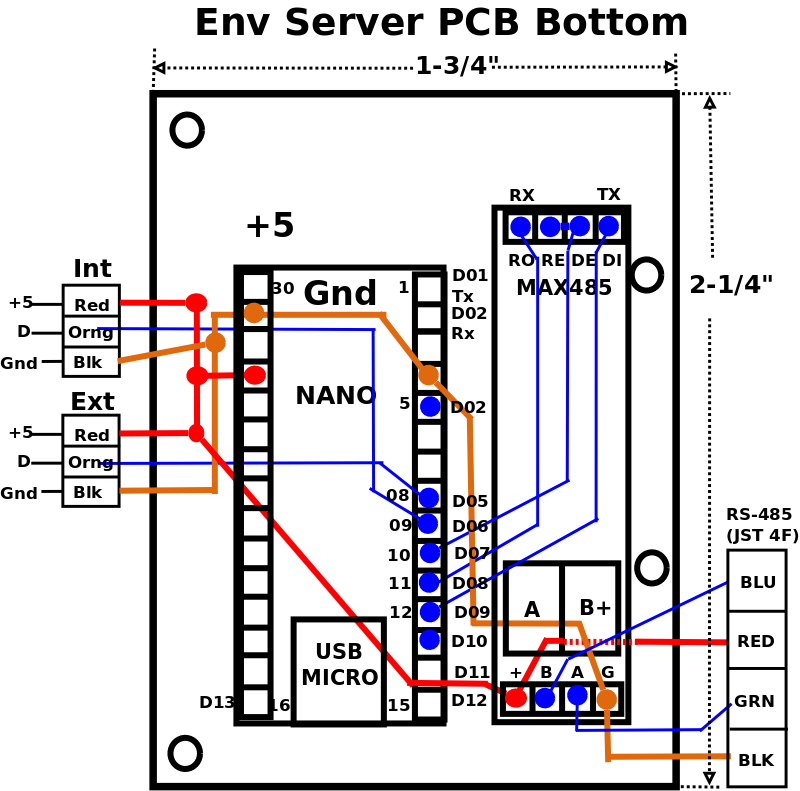

I originally used a Nano breakout with screw terminals, but when I converted to RS-485 (added a MAX485), I had to make a PCB the same size as the Nano breakout.

|

Click For Larger Pic |

|

|

|

| |||||||||||||||||||||||||||

|

Parts cut out, ready to miter. The bottom doesn't need mitering and already has the support blocks glued on. |

|

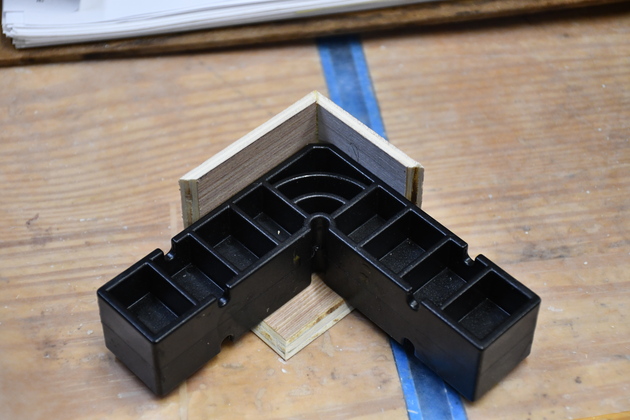

Starting to glue, here I'm gluing one side and one end to the top. The mini-Clampit makes everything is square. |

|

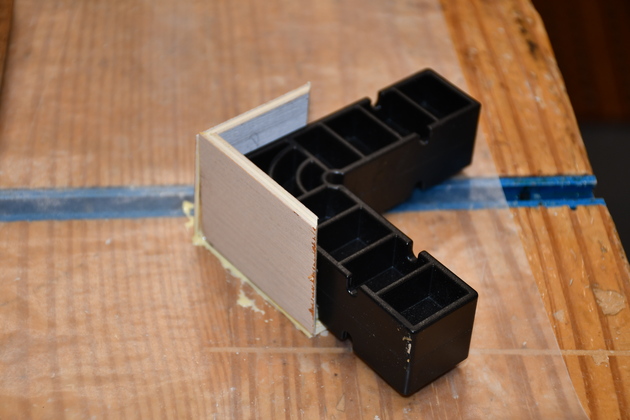

Different angle, I'm gluing one side to an end and the top (now on the bottom). The mini-ClampIt keeps every thing square till the glue sets. Normally, when gluing a larger mitered box together, I'd use a set of my Clamping Cauls. |

|

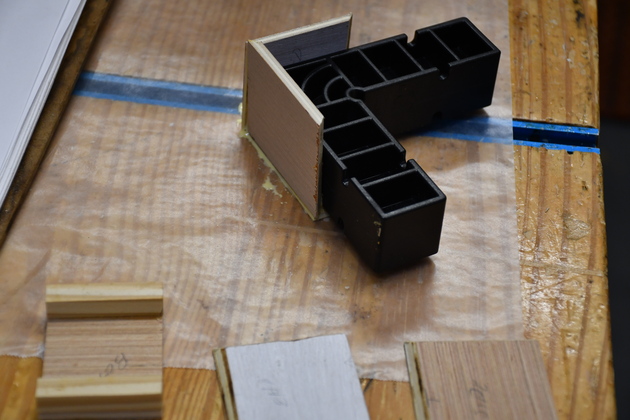

Here I'm gluing the other side and end to each other. Again, the mini-ClampIt holds everything square. |

|

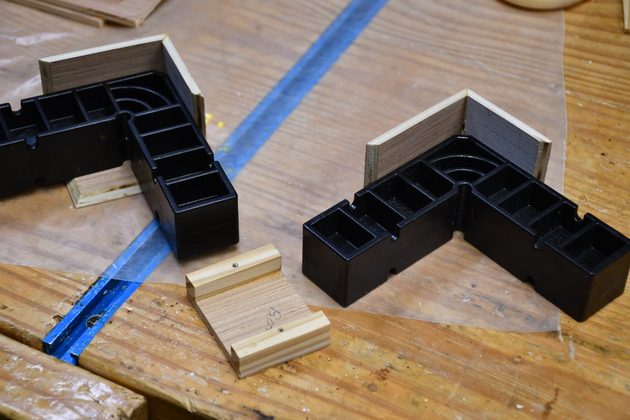

Side by side, now all that remains, after the glue sets, is to glue the two pieces on the right to the 3 on the left, then drill the holes for cables and mounting screws. |

|

Gluing the last end/side pair to the other end/side, and top. You can see the bottom off to the right. |

|

After final glue. The cover and it's bottom. |

|

|

|

Two air holes on the back side. |

|

Mouse Holes cut. |

|

Painted an outstanding color. |

|

|