| |

|

|

|

|

Fitting A Wynn Environmental Filter to the Jet DC-1100

AKA - A Better, Less Expensive Filter for the JET DC-1100

|

Someone asked who I was, my name is Paul Turner.

07/29/21: Another Wynn filter NBR

04/29/19: Different Wynn filter NBR

11/20/15: Replace cake plate with plywood cover.

08/08/15:

Moved the DC-1100 with Wynn Filter to the ceiling.

04/16/15: Added Caveat.

02/25/12: better pic of flange, fixed typos, add links to WynnEnv.

02/23/12: original article.

Feb. 2012

(doesn't come with paddles or set screws).

The original Jet DC-1100, requires VERY FREQUENT CLEANING of it's filter.

The Jet filter has internal paddles, operated by an external handle daily, to knock down the large clumps of wood chips that build up inside.

I think the paddles and the Jet name makes the Jet filter so expensive (price ranges from $344 to $409 last time I checked).

You don't need internal filter paddles with a cone (or Thein Baffle) installed, so the Wynn is perfect (much more effective and less expensive filter).

I noticed the new Vortex Cone Jets still have paddles on the filter, I wonder how effective their cone is if they still need paddles?

One additional problem, the Jet filter has a collar around the outside of the seperator with 4 large "set screw" clamps around the outside of the lower edge that clamp to the outside of the separator.

The "set screw" clamps only hold by friction, not a mechanical "catch point".

You have to hold down slightly on top of the filter while tightening the 4 bolts around the edge to get a decent seal.

This is a little unhandy and may work loose with vibration while under positive pressure.

Any questions or comments about these pages, please email  .

.

During the research on improving my Jet DC-1100's particle separator, I ran across Wynn Environmental's dust filters.

They have a lot more filter area, even though they appear slightly smaller, and filter particles to about 1/4 or 1/10th the size of the Jet filter, and cost about half of what a Jet filter costs.

You don't need the paddles on the inside of the filter cartridge after upgrading to a cone.

So I set myself the task of fitting one to my DC-1100.

Here are the results.

BTW, this approach will work to upgrade a DC-1100 bag type (or most other large dust collectors) to use a canister filter.

I received the Wynn Envronmental C1425 yesterday (02/22/2012), so today I'm working on fitting it to the JET DC-1100C.

Dick Wynn suggested the flanged version of the filter (C1425) which opens a lot of mounting options.

After measuring and thinking about this, I have decided to take another of Dick Wynn's suggestions and make a 3/4" plywood donut that fits within the top of the Jet's separator housing, and is flush with the top.

Dick also noted I could use the open top version (C1425) or a closed top (C1425C), both have flanges.

The open top with a plastic "cake plate" cover would allow me to watch whats going on down in the throat of the separator, so I opted to go this way.

The flange has 3 bolt holes at 120° spacing to hold the filter down and slightly compress the gasket, insuring a good seal.

There is a fourth bolt hole between two of the others, but I decided I didn't need it.

The flange also has a turned up lip (probably for strength) which limits the kind of bolt head, so I decided to use a 1/4-20 round head bolt with phillips slots which fits nicely and still gives me quick on/off using an electric screwdriver.

The Jet's separator housing isn't perfectly round (it doesn't need to be) but for the most part is it 19 1/2" inside diameter.

I cut a 3/4" plywood circle to fit (19.5" diameter), then cut a 14" concentric hole for the air to pass (note the Jet's separator throat is 9" in diameter) thus creating a donut.

I painted the donut with clear polyeurethane and let it sit overnight.

The clear polyeurethane's hard surface allows the gasket to seal better and eliminates the porous surface for dust particles to be trapped.

I drilled 4 holes, around the edge of the Jet's separator, about 3/8" below the top, chamfered them with a larger bit, to mount the 3/4" donut.

Then I centered the C1425 on the donut and marked where three of the holes in the flange were on the donut.

There are 3 holes in the flange, at 120 degree spacing with a fourth between two of the others, I chose to use the 3 at 120 degrees.

I drilled a pilot then 1/4" through holes, and counter bored from the bottom for the top of a 1/4-20 tee nut (5/16" counterbore).

I ran a bead of silicone sealer around the edge of the donut after attaching it to the separator with four #8 X 3/4" screws.

Dick also recommends that you use 80 PSI or less air pressure when cleaning the filter.

This turned out to be a very quick project, it lasted two days since I let the paint and sealer dry overnight.

The acutal effort required was only 3 or 4 hours.

In the Jet's case the Wynn filter was Physically a little smaller than the original Jet filter, but has better filtering MERV 15, 99.999% @ 0.5 Microns, the jet is only rated at 2 micron particles, making the Wynn Environmantal 4 times better (smaller particles).

If your DC is smaller than the Wynn, your donut will need to be larger than the separator, it'll sit on top of the separator, and you can use small (2 or 3") stanley angle braces attached to the inside of the separator and to the under side of the donut.

New Wynn Filter: 35B222NANO

In 2019, I decided I need a new Wynn Filter and went to their site to order one.

Alas, they don't make the C1425 anymore, so I talked to Dick Wynn who suggested one of their new filters a 35B222NANO (removable top) or a 35C222NANO fixed top.

I ordered a 35B222NANO and when it arrived, it only took a few minutes to remove the old C1425 and replace it with the new filter.

The new filter will clamp onto the same donut I originally cut for the C1425 filter

I measured where the 4 mounts should go (took length of a 90° chord), drilled pilot holes, screwed the mounting tabs to the existing donut, placed the new filter, and tightened the clamps.

My only gripe is the attachment clamps were only for slot screw driver instead of a phillips, the phillips would have made it a lot easier.

See pics.

New Wynn Filter: 18R220NANO

In 2021, I ordered another Wynn Filter: 18R220NANO, it appears to have a flange on either end.

The flanges allow me to do away with the pipe clamp latches and just use 1/4-20 bolts, which are much easier to deal with.

Wynn Filter C1425

|

The Wynn Environmental C1425 arrived.

|

|

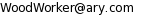

The C1425 has a flange around the bottom.

The flange has a rolled up lip (probably for strength) so it limits the kind of bolt head or you would need a spacer block to raise the bolt head above the flange lip.

This flange doesn't require a lot of stress so it's width isn't a big problem.

The simplest technique seems to me to use a 1/4-20 round phillips head bolt, which fits nicely inside the flage.

|

|

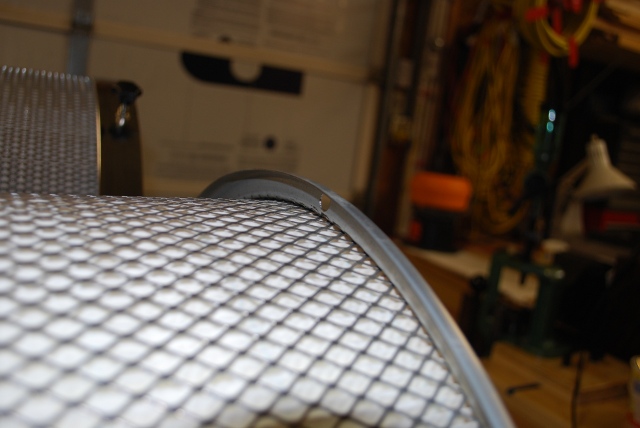

The C1425 has an open top (opposite the flnged end) which I will enclose with a "cake plate", again, per Dick Wynn's suggestion.

You could use a piece of wood as an alternative to the cake plate.

I would guess the open top allows these filters to be stacked to double the air capacity, if you choose to do that.

|

|

The cake plate after sealing it.

You can see the silicone sealer bead, I put a lot on since the cake plate had a small contact area.

I wanted it turned this way to make it a little easier to clean, since it is a little higher than I can see without getting on top of something.

|

|

This is where my DC-1100 lives, back against the wall, you can just see the "Dust Dawg" filter to the left of the bandsaw and behind the other equipment rolled up in front of it.

|

|

Both filters side by side.

You can see where I sealed the gasket to the new filter (not very uniform I'm afraid) to make sure the gasket stays in the correct place when being mounted.

The Wynn is slightly smaller in diameter than the Jet, but, the Wynn's pleats are 9/16" deeper than the Jet, yielding a lot more filter surface area.

You can see one of the paddles and lower support inside the Jet filter.

If the Jet's separator worked better, you wouldn't need the paddles in the filter, and it could be way less expensive.

I don't have any concerns about the Wynn Filter not having paddles after seeing the improvement by adding the cone to the separator.

You can also see the Jet's gasket, the band that goes around the bottom edge of the Jet and the 4 "set screw" clamps that hold the Jet on.

|

|

The Jet with it's filter removed.

Note the "sawdust hill" in the center of the bag, this came about when I added the tin man's hat and brim.

I made the 4 X 4" plenum several years ago.

|

|

Of course there is a little fine dust, as shown here on the tip if my finger.

But that is what the filter is for.

|

|

The donut sitting on top of the separator ready for a test fit to the separator.

I used a piece of rough 3/4" plywood which I had available, then painted it (after pic taken) with clear polyeurethane to seal the wood, reduce dust catching pores, and allow a better seal.

|

|

Smooth cut, I am surprised it looks this good.

I used a Festool PSB 300 EQ jigsaw, the Festool circle cutter and a Bosch T101A0 blade.

|

|

The bottom of the donut with three 1/4-20 tee nuts.

Seen here after the donut was painted, I installed the 1/4" tee nuts from the bottom.

|

|

The filter to donut test fit and tee nut with 1/4-20 round head bolts.

Don't torque the bolts down, it only requires enough pressure to slightly compress the gasket, just get a good seal so air (and dust) doesn't leak out.

|

|

The donut in the Jet DC-1100's separator.

You can see one of the four 1" screws holding the donut inside the separator.

|

|

The bead of silicone sealer I used around the donut.

|

|

And finally the entire unit with the Wynn C1425 filter attached to the Jet DC-1100 ready to test.

I usually work in pine and fir, but you can see a dark ring near the bottom of the sack where I did a project in red oak.

It's interesting how the dust collector can reveal something of your woodworking history.

|

|

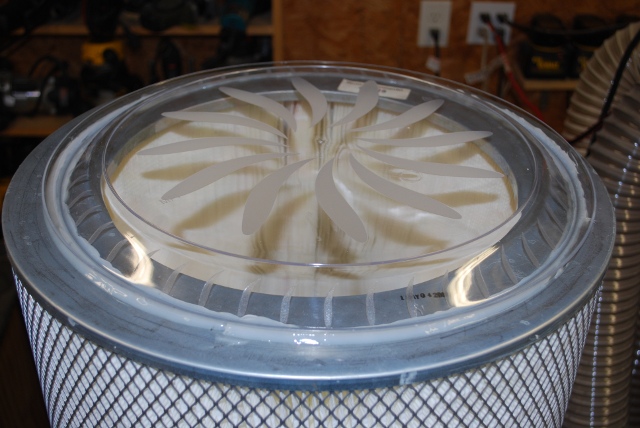

Here is what it looks like "Down the Hole" while the Jet is running.

You can see whats going on in the separator throat better with your naked eye than this pic shows (due to reflections).

You can just see the inside edge of the donut around the inside of the filter.

Now I can get up on something and look into the filter and separator throat to see whats going on.

I got Betty to throw handfulls of sawdust into one of the Jet's intake hoses while I watched.

The air is moving at about 90MPH so when sawdust does come in, its quick, but note, no build up on the top of the throat.

|

In November of 2015, I cleaned the filter and the cake plate came off, again.

So I made a 1/2" plywood cover, ran a foam tape gasket around the top of the filter and screwed it down, no leaks.

The new cover is removable which makes cleaning a lot easier.

|

Here you can see the filter top with a foam tape gasket at the top.

You can also see the outline of the new top and screw holes near the filter's top hole.

|

|

The new plywood cover being painted with clear polyeurethane.

|

|

Closer look at screwhole.

|

|

And matching screwhole in filter top.

|

|

Screws that hold the new cover down against the gasket.

|

|

New cover screwed down on top of filter.

I put the plywood's 'A' side toward the gasket so It would have a good seal.

|

|

Closer look at screws and alignment marks.

I drew the circle where the inside of the filter would be and so I would know where to drill the screw clearance holes.

|

|

Side view of new cover.

|

|

Here is a late 2015 pic of the donut after I removed the filter to clean (and ultimately replace the top).

Note the bolt holes that hold the filter down (there are 1/4-20 tee nuts below).

Also notice the clean throat and only a tiny bit of dust on top of the support bar.

This is after I moved the DC to the ceiling.

|

|

The DC on the ceiling while the filter is being cleaned.

|

New Wynn Filter

|

A little closer look.

You can see the front clamps holding the removeable lid and holding the filter to the donut.

|

|

One of the front side lower clamps.

|

|

You can see the bracket holding the clamp to the donut.

|

|

One of the 4 upper clamps securing the top.

|

.

.