|

|

| ||

|

Air Compressor

| ||||

|

|

| ||

|

Air Compressor

| ||||

| Back to Work Shop | Replacement | Info | Portable Air Tank |

The shop air compressor is a 18 year old Sears/Craftsman 919.167312, 2HP, 120V sigle phase, 150 PSI, unit with a 30 gal. tank.

The compressor pump is oil free.

I don't use the compressor frequently, but I have several pneumatic tools, which make some jobs much easier.

It also works (with a regulator) for cleaning out my Wynne air filter on the large dust collector.

My friend Bill Kesler and I installed this air compressor in 2003, right after I bought the house. I removed the wheels, handle, and air pressure gauge, built a wooden cradle for it to sit in, and replaced the plug (in the bottom of the tank) with a bushing so I could attach 1/2" PVC. I built a water trap, with a drain valve and pressure guage (from the pressure switch), against the shop wall. The air compressor has worked perfectly ever since it was installed. Here is a near model Sears compressor.

I don't use my air compressor heavily, but when I need it nothing else will work!

I blow out the DC6 filter several times each year, occasionally I air up a tire, some times I need to use some of my impact tools and I occasionally do a little spray painting.

This oil free air compressor has been installed in the attic above my workshop (was garage) for about 18 years. Note: This oil free compressor is awfully noisy! The Sears system's (919.167312) has a 30 gal. tank (certified above 150#), and is already plumbed into my air distribution system. My air distribution system includes a water trap (all water in the tank & system drained into it) with blow out valve, guages, and valves to allow me to cut portions of the system out, etc.

|

Air Tank in Shop Attic

We mounted it with the elongated tank vertical. The bottom hemisphere had a plug which we replaced with a 1/2" bushing and PVC adapter. The 1/2" PVC gently angles down to the top of the Water Trap. |

|

Simple Water Trap.

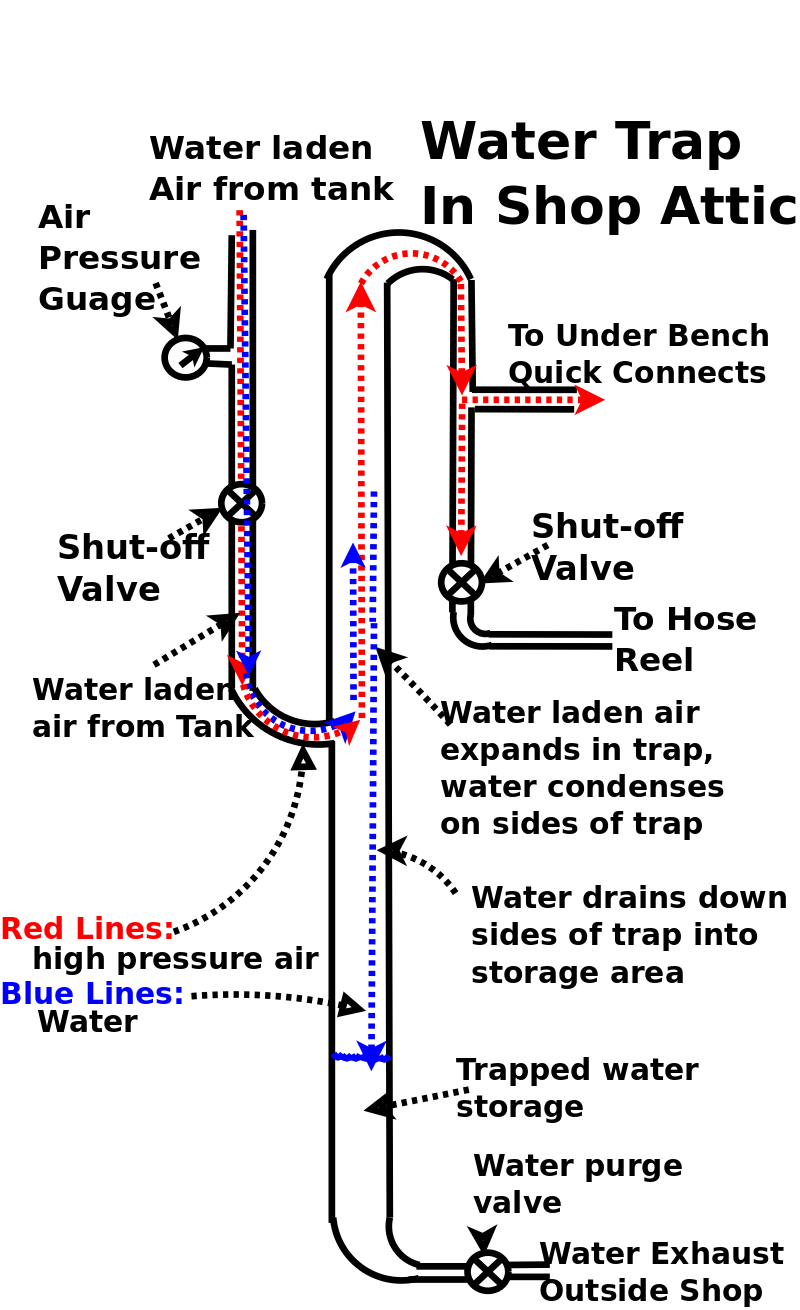

Click to enlarge then follow the dotted red and blue lines. The high pressure air flows down from the compressor tank (1/2" PVC), into the water trap (1" PVC), then up through the water trap, at a slower speed (thanks to Bernoulli's Law) and out the top, allowing most of the suspended water to condense on the sides of the water trap and collect in the bottom half. The water collects in the lower half of the 1" 8ft. tall PVC. After exiting the top of the water trap, the air goes down through another 1/2" PVC, to the outlets plumbed in the shop under the front of the benches and to a hose reel with it's own cutoff. At the bottom of the water trap (1" PVC) is a water purge or drain valve and a water exhaust line to the outside. This drain valve is used periodically to exhaust the water out of the water trap. An even larger water trap PVC would be appropriate, but I could only find PVC tees etc. from 1/2" to 1". Remember, compressed air plumbing is like sewer plumbing, water has to flow smoothly, by gravity, to a chosen low point where it collects. Click for larger Pic. |

|

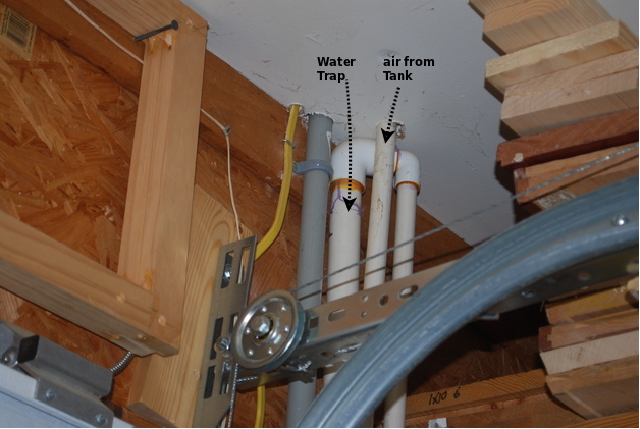

Here you can see the 1/2" PVC coming through the ceiling, and the top end of the water trap (output).

The grey PVC is for electrical power to the outside motion detector lights. |

|