|

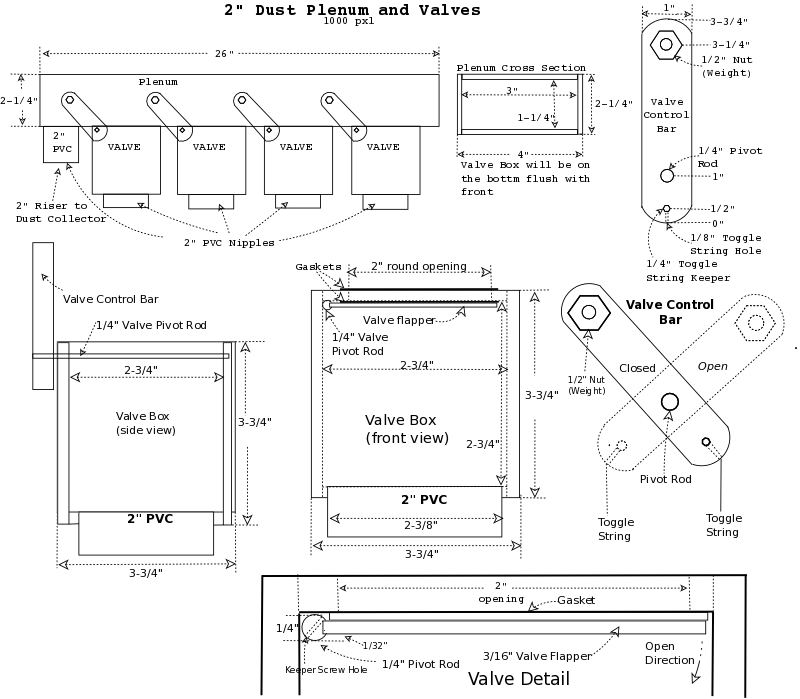

2" Valve Construction |

|

2" Valve Construction |

| 2" Plenum Page |

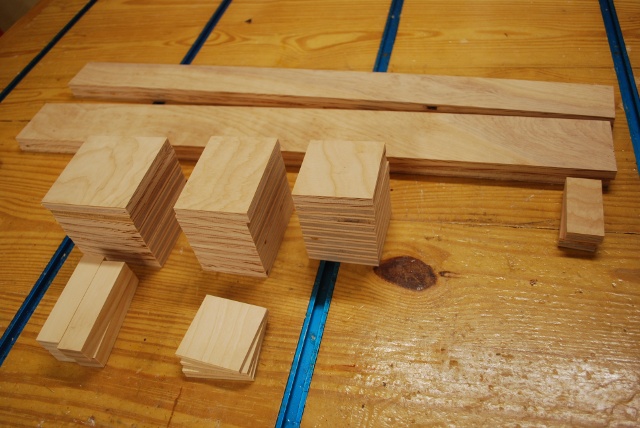

| Birch plywood parts sawed out for plenum and valves. |

| Closer look at a valve top being sawed, notice the hole is off center. |

| Sanding the valve top and bottom holes smooth. |

| Sides being glued onto tops. |

| Screw hole being drilled in pivot rod (1/4" oak dowel) For more pics on how I do this please see pivot rods in the 4" plenum page. |

| Closer look at screw hole in valve pivot rod. |

| The screw hole is a pilot hole for the screw but I made it just fit a tootpick to keep it at the correct angle while I'm machining the flat for the valve flapper. Please take a look at the pivot rod machinging on the 4" system. |

| Here is how the flapper fits into the flat on the pivot rod, the right side should be flush with the side of the pivot rod. |

| Flapper glued to the pivot rod. |

| The far end of the pivot rod has 1/4" to fit into the blind 9/32" hole int the upper left corner of the back of the valve box. |

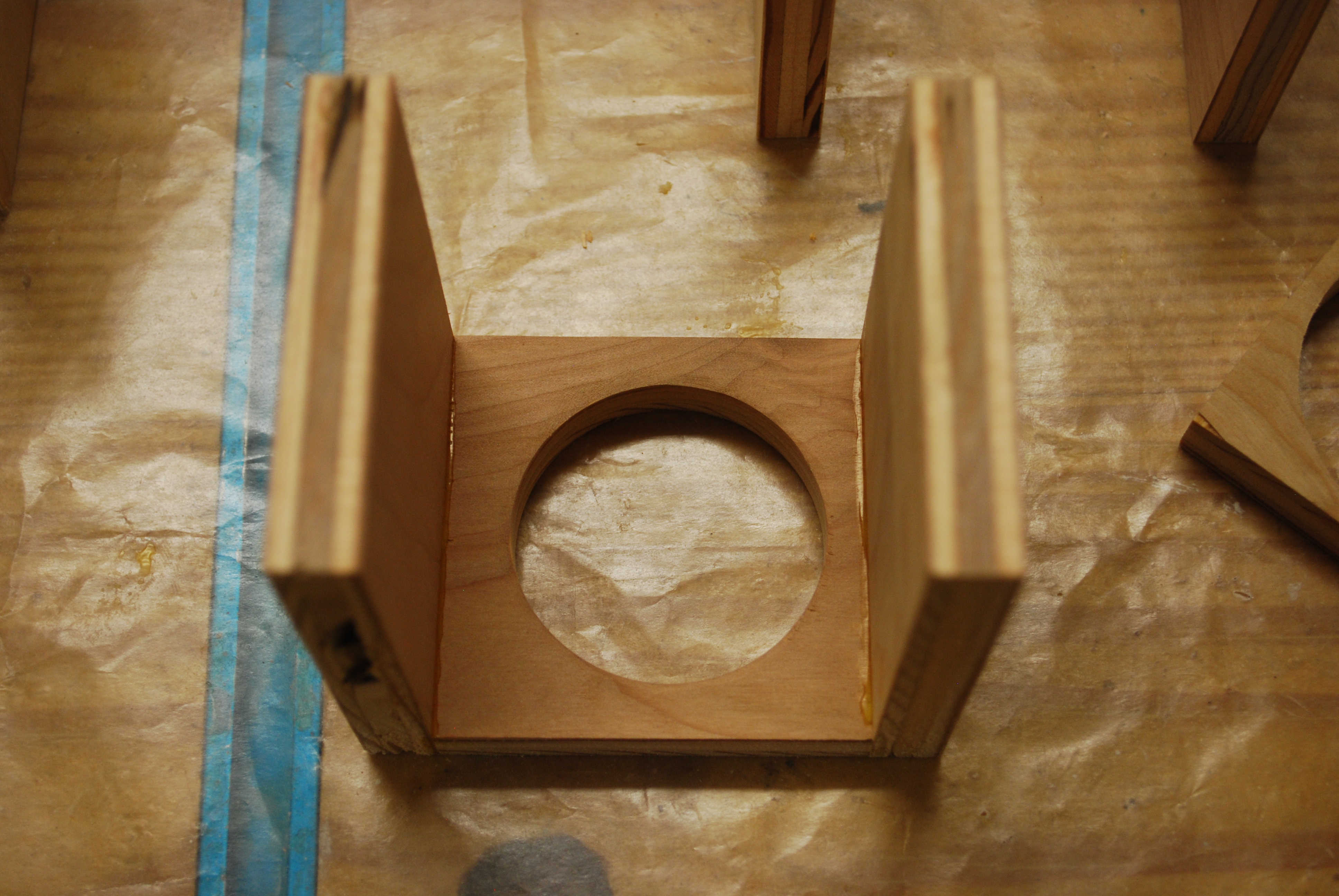

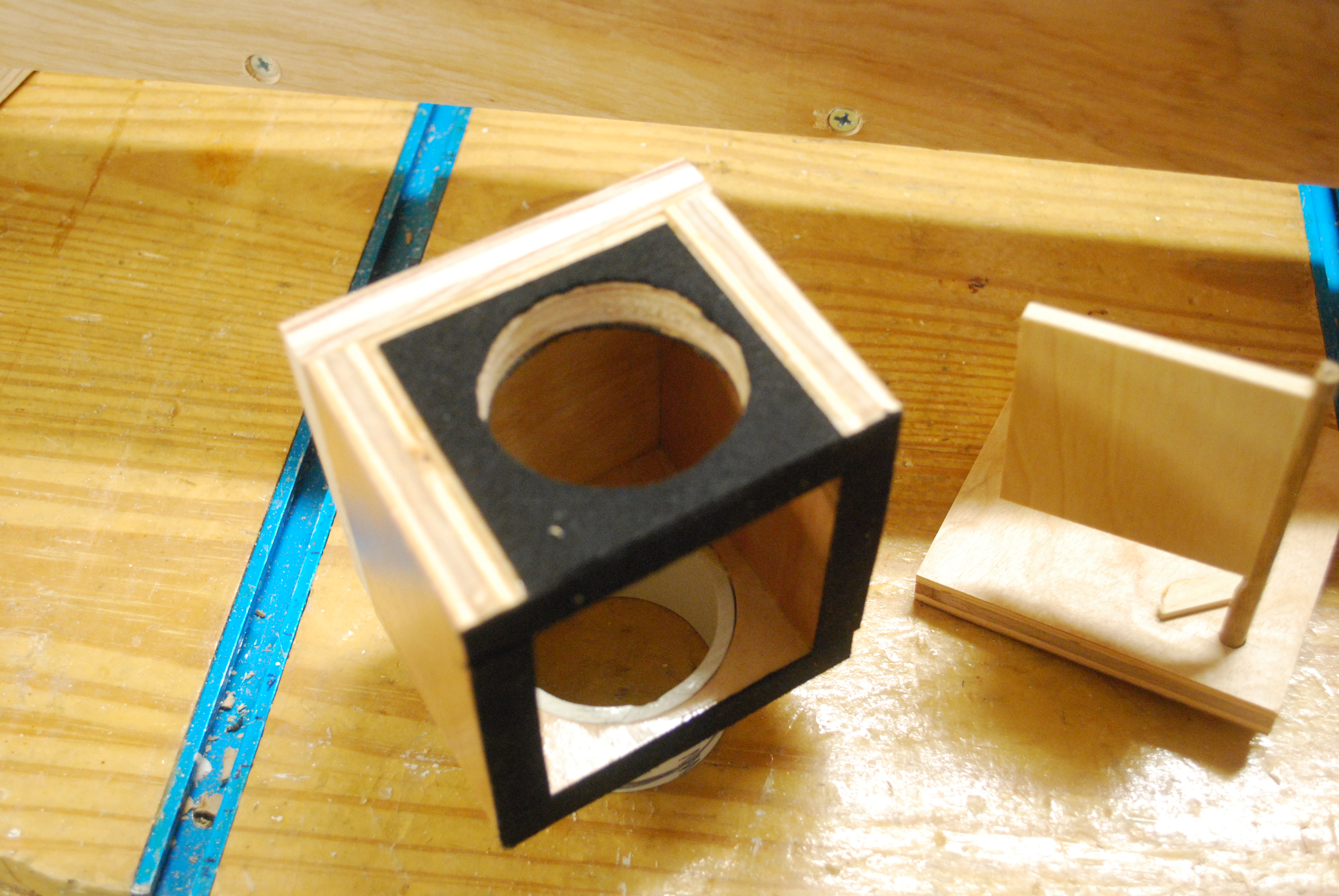

| Looking up into the valve box with the sides on, you can see the 2" hole is offset to the right to allow clearance for the pivot rod. |

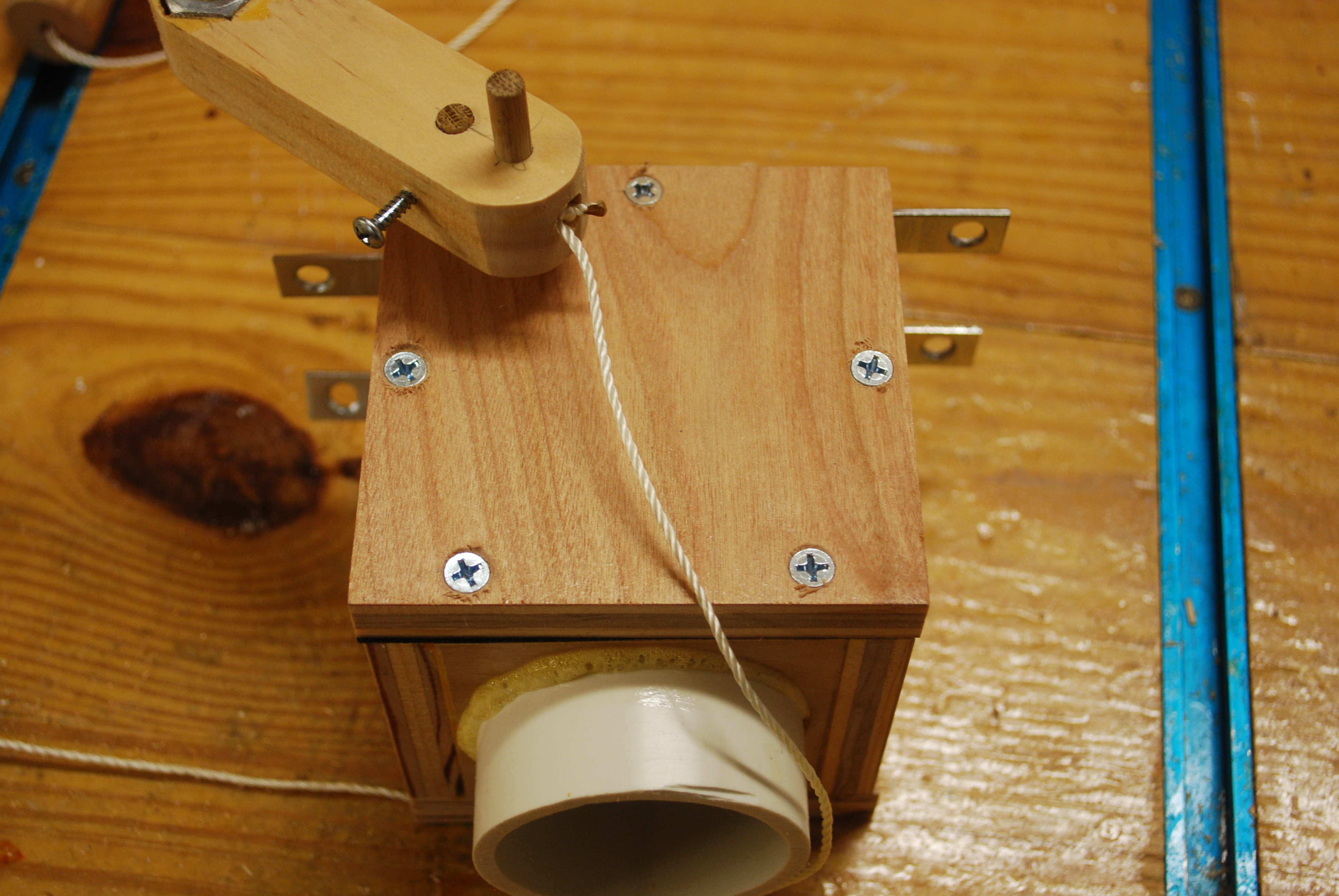

| PVC short nipples being glued into the valve box bottom. The 2-3/8" hole is a good tight fit for the OD of a 2" PVC, I cut the short nipples from a piece of 2" PVC scrap. |

| Gorilla Glue just applied, I put a ring around the bottom end of the short nipple then inserted and twisted it to spread the Gorilla Glue. |

| The Gorilla Glue foaming up, this is why it is so good for making air tight joints, it sticks to everything and foams up a little to fill any voids. |

| Valve boxes with bottoms glued on I already painted the inside of the valve box with clear poly. |

| Note the short PVC nipple is flush with the inside bottom of the valve box. This cuts down on turbulence. |

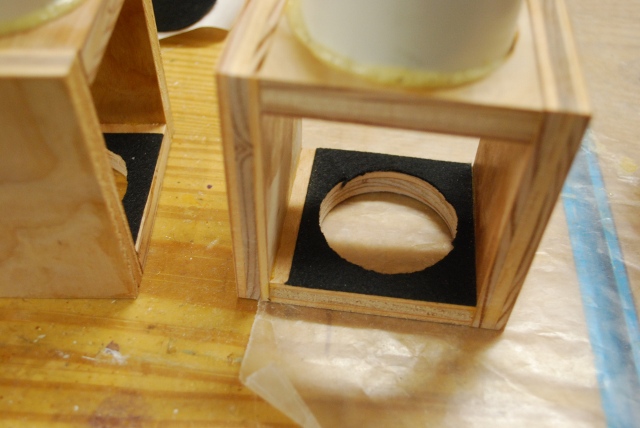

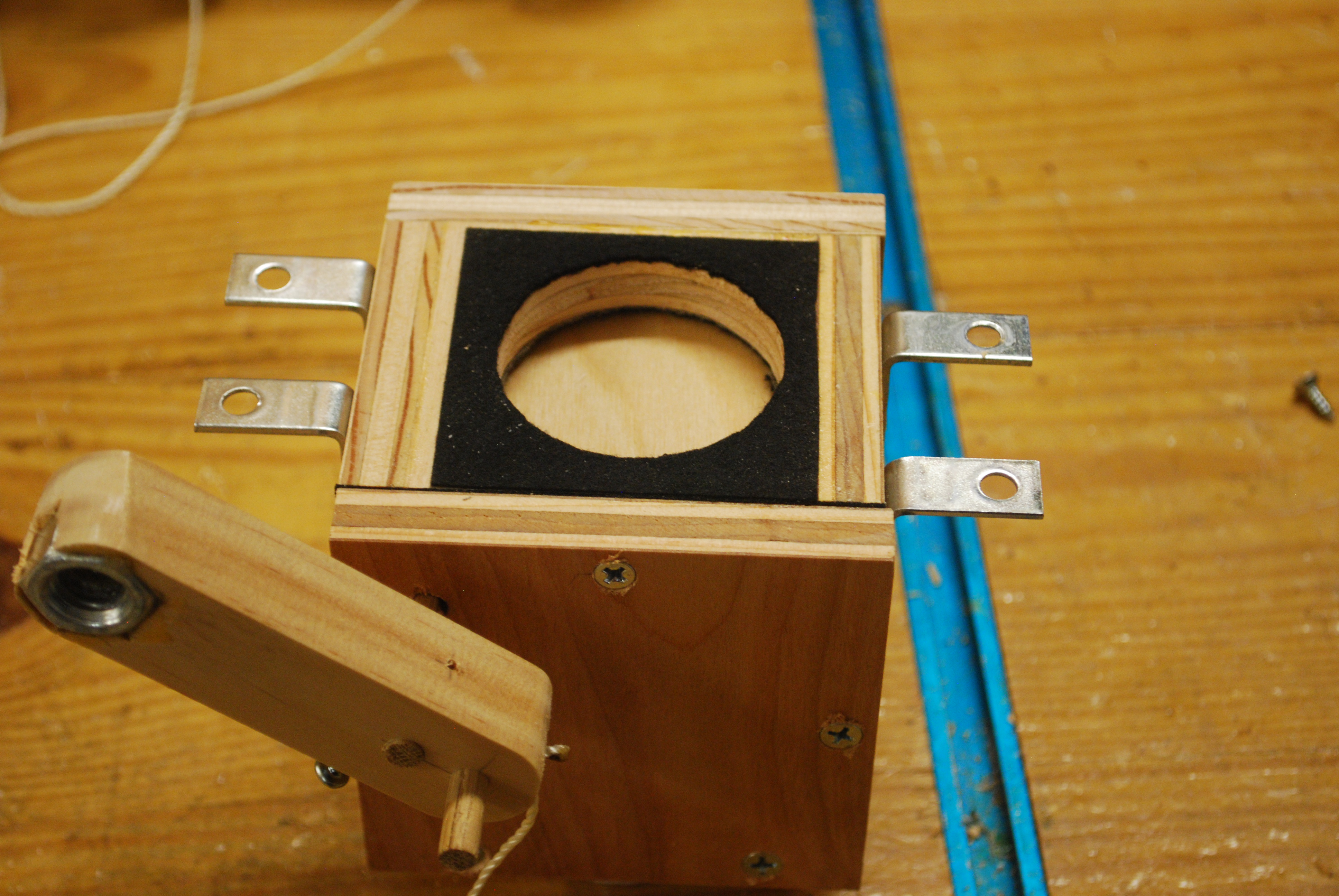

| Self adhesive pad sitting in underside of valve box top. Note the pivot rod clearance on the right. |

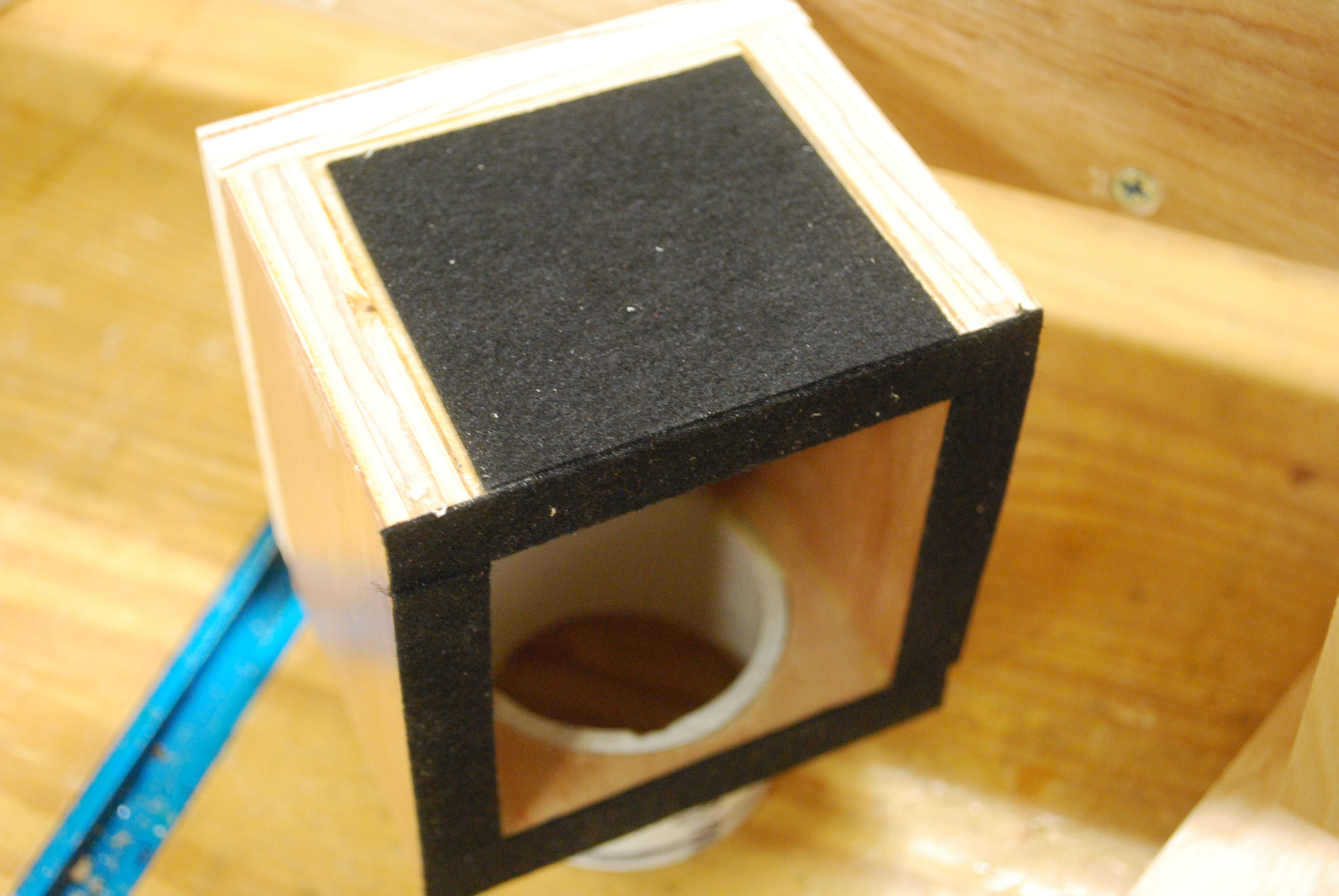

| Valve flapper gasket stuck to underside of valve top. There will also be another gasket on top of the top between the valve box and the plenum. |

| I'm using an X-Acto Knife to cut out the hole. |

| Hole cut in gasket material. |

| Valve flapper fitting. The valve flapper must move very freely, here I'm holding it closed by the pivot rod. In the next pic I release the pivot rod and the valve should fall open. |

| Valve flappers and pivot rods ready to paint. |

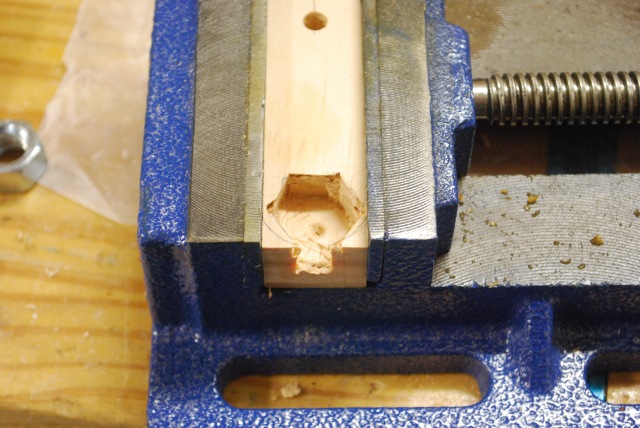

| Valve control bar, round counter bore has had 6 corners chiseled in to make a Hex for the nut weight. The round counter bore is 3/4" in diameter, and 3/8" deep. |

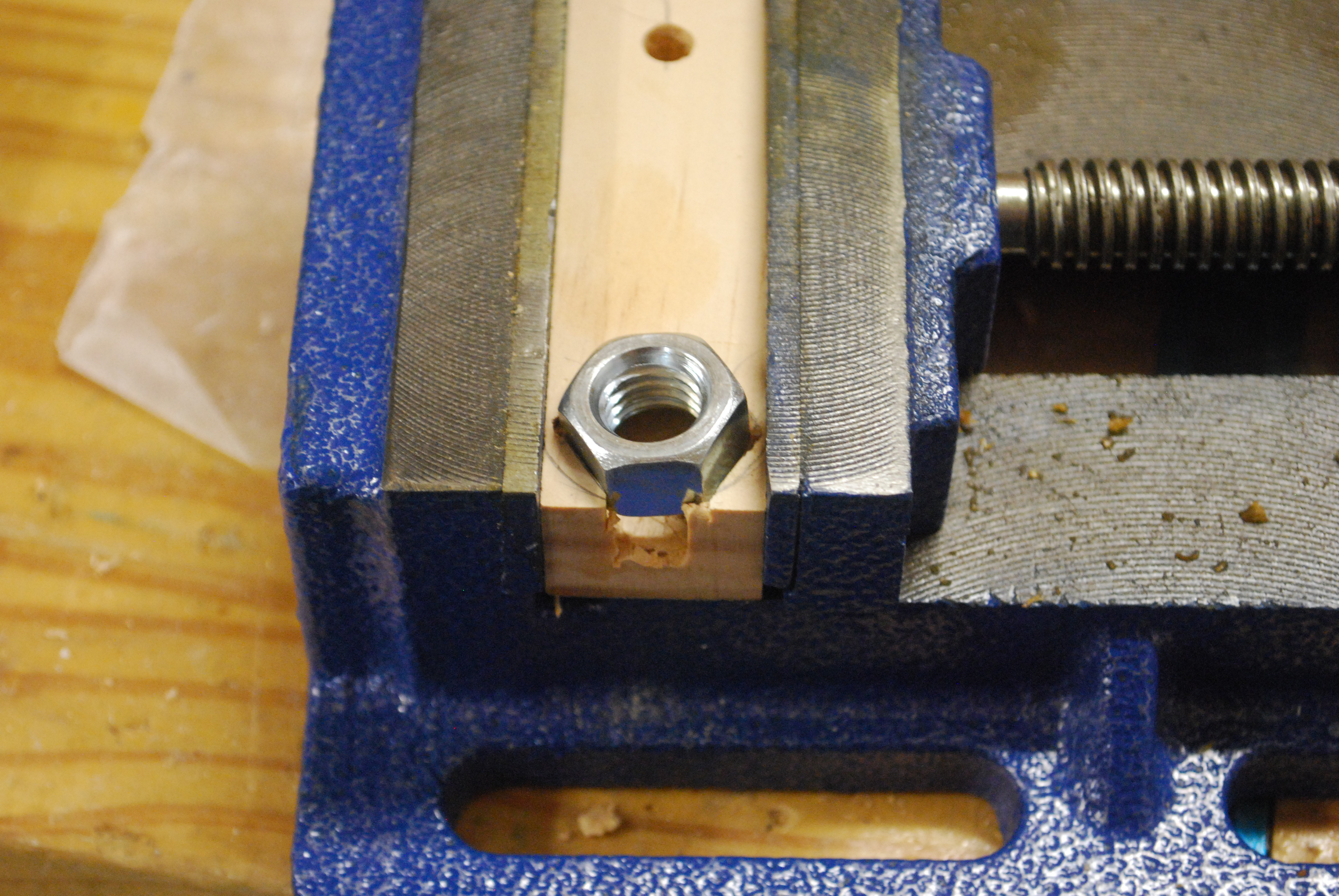

| Control bar weight test fit of the 1/2" nut (weight). |

| Valve knobs painted, chamfered, and drilled. These knobs go on the end of the toggle string. |

| CLoser look at valve knob. |

| Gasket stuck over 2" hole on top of valve. This gasket seals the valve box to plenum's bottom. You can also see the valve box's front cover gasket. |

| 2" hole cut out in valve box gasket. The valve box front cover with the flapper and pivot rod are laying to the right of the valve box. |

| Knobs, keepers and toggle strings ready to assemble. |

| Closer look at the toggle string keepers. THe notch is where the string will fit, the pointed end helps push the keeper through the loop in the top of the toggle string. |

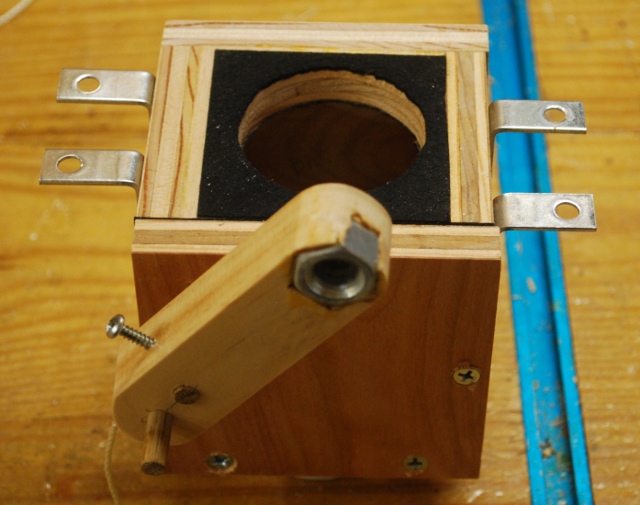

| Finished valve, open, painted, with control rod, toggle string, and mounting brackets. The valve should fall completely open when you move the control rod just past center to the right. |

| Finished valve, closed, the valve should completely close when you move the control rod just past center to the left. |

| Front of finished valve, note the screws holding the front on, control bar, end of the pivot rod and the toggle string keeper. |

| view looking upward at a valve. |

| Valve mounted on plenum note the front of the valve must be flush with the front of the plenum. You can also see the two mounting brackets on this side of the valve. |

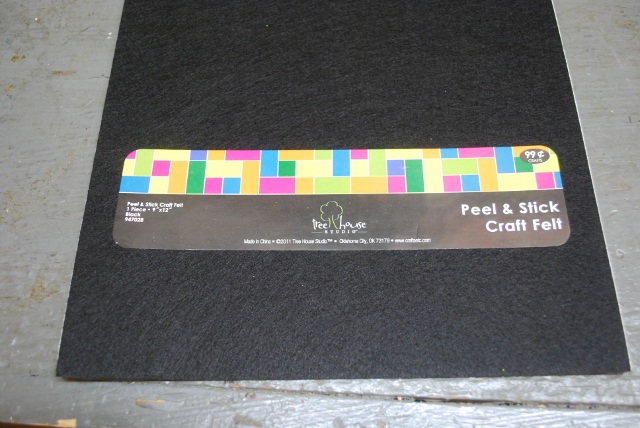

| Here is one of the pieces of "Peel & Stick" I bought at Hobby Lobby, its 9 X 12". |

| With a 12 ga shell for reference, the felt is about 1/32" thick. |