|

|

|

Countertop Paper Towel Holder

| |

|

|

|

Countertop Paper Towel Holder

| |

| The Base | Bushings | Final Assembly | Sand Casting |

| Diagram | Prototype Diagram | Circle Maker | Cylinder Maker |

We had an under cabinet paper towel holder, which I had to remove, so Betty wanted something to keep the paper towels organized.

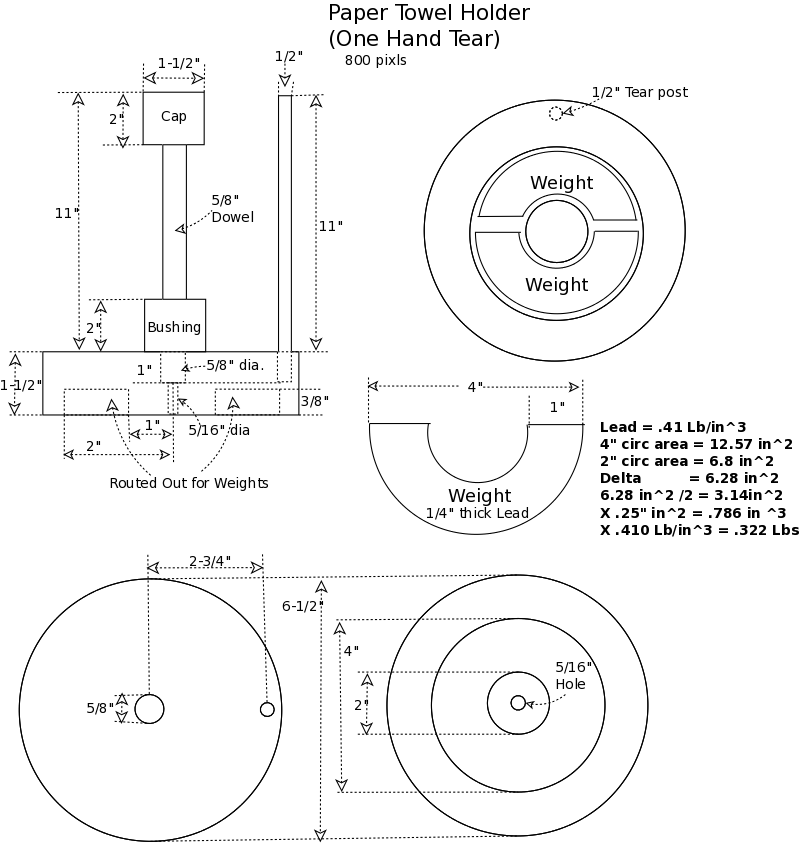

This first unit is experimental, I want a one-handed paper towel holder, that is, you can tear off paper towels with only one hand.

I want to weight the base so you can pull against it without using a second hand to hold it in place.

I want a vertical bar (tear post) to tear against and to keep the paper towels from unrolling by themselves.

The weight must be on the opposite side from the tear bar.

I might need to have the anti-unroll bar keep a little pressure against the outside of the roll.

If there is a way, I would like to add a little resistance to rolling to help in the tear, this also adds to the weight requirement.

The wooden bushing at the top and bottom should be just smaller than the ID of the paper towel roll center (cardboard) to provide the max resistance.

In order to have a one hand tear, it needs to be heavy enough so id doesn't scoot across a countertop or turn over when you jerk off a paper towel at it's separation. In order to accomplish this, I am using a thick base which is hollowed out and weighted on the opposite side from the tear bar. The base will have rubbery shelf liner glued to the bottom to prevent skids on kitchen counters. The weight will be sand cast from lead, then sealed in casting resin. The center vertical bar is 5/8" with 1-1/2" bushings and caps. The tear bar is 1/2".

Sand Casting

This is the first time I have ever tried to cast metal, and I sure learned a lot during the casting operation.

I now know I need a larger ladle, it must hold enough for one entire cast piece.

I also need to have extra metal in the furnace, if I'm ladling so the ladle is filled with each dip.

Now I understand one of the reasons for using ceramic crucibles to melt metal!

On 02/01/16 I built another group of Paper Towel Holders (4) and when I got to the weight casting part I realized how much I learned from the first attempt.

Everythning went much easier and I did a much better job, but still not great.

|

Two 2x4s, 7" long, after edge laminating. |

|

Square blocks in process of becomming circles. See the Circle Maker page. |

|

Basic shape cut out using the Circle Maker, center hole drilled. |

|

Bottoms routed on Circle Maker. |

|

The base on the right is about to have it's top edges rounded like the one on the left. |

|

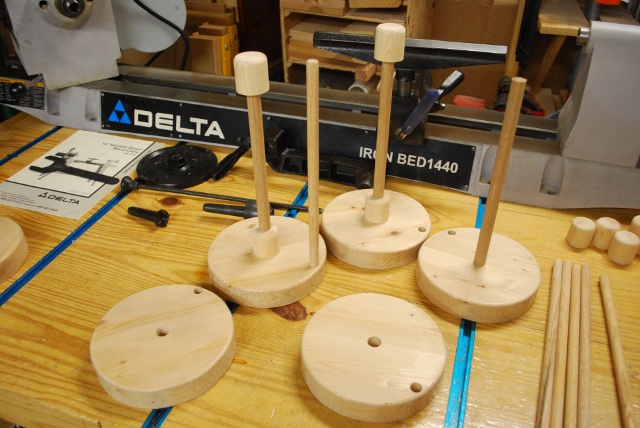

Square stock being turned into 1-1/2" dowels on the Cylinder Maker. |

|

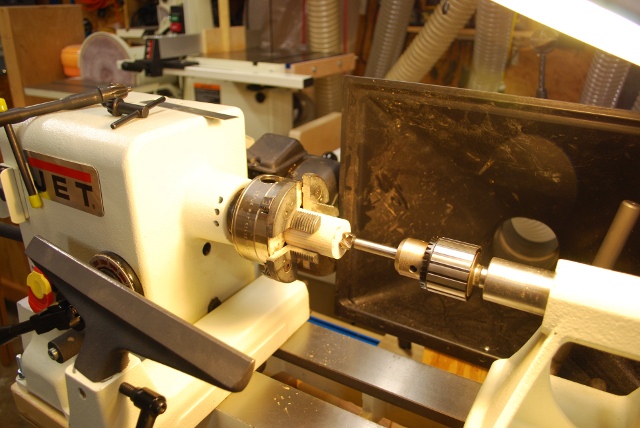

Bushing being drilled on the lathe. |

|

Bushings after center drilling on the lathe. The lower bushings (on left) have the hole drilled all the way through, the upper bushing (on right) only has the hole drilled 1" deep. |

|

After the bushings and caps are turned using the Cylinder Maker and bored along with the center and tear posts. The bushings bored all the way through (left) will go on the bottom above the base and the caps only bored part way will be on top. Here is the final assembly. |

|

Lead weights in place and resin being cast into the hollow base. Notice the resin is mostly clear. |

|

After resin sets, it becomes opaque. |

|

Bottom bushing being slid on to the center post. |

|

Top bushing being placed. |

|

Here are more test fits of parts.

|

|

The five that will be gifts. |

|

Closer look. To tear off a paper towel, grab the end of the roll, pull out whatever you need then quickly tear up, against the tear bar, at about a 45° angle. |

|

Another look at one on our bar. |

|

Finished paper towel holder with a roll installed. |

|

Second Batch, finished on the workbench. |

|

Another angle. |