|

|

|

Sand Casting

| |

|

|

|

Sand Casting

| |

| Making Casting Models | Making Green Sand | Making the Mould |

| Casting the Weights | Lead Weight Diagram | Paper Towel Holder Project |

I wanted to cast some lead weights for a project I was making so this page is the result of that project.

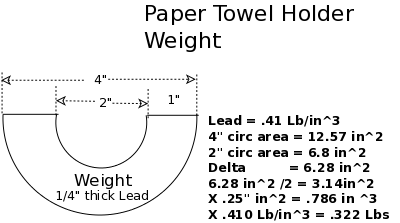

I needed about 1/2 LB per weight so I figured I needed hollow half circles, 4" across, with a 2" center hole, and 1/4" thick.

A model of this occupies .786 in^3, lead weighs .41 Lb/in^3 so the total weight is .322 Lbs.

These don't have to be pretty, just heavy!

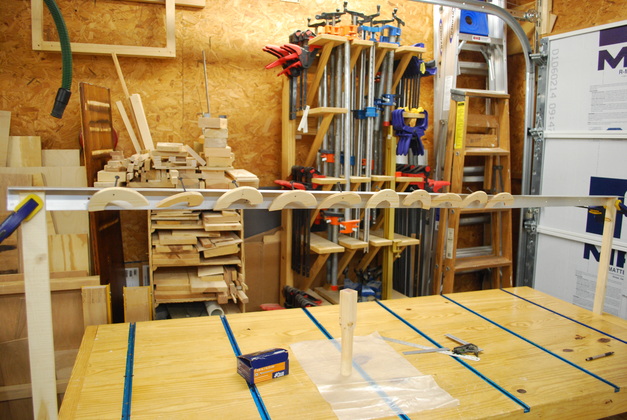

| I am making 5 paper towel holders, so I need 10 of these weights. |

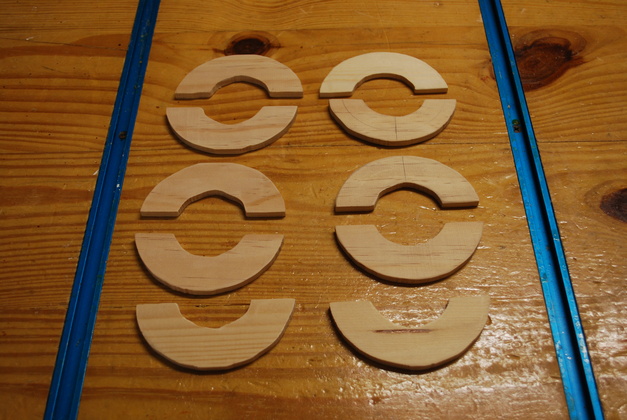

| Here are a few cut out. I'll sand and paint them to make them easier to get out of the greensand. |

| Here they are sanded. |

| I used my 10" bandsaw and the inside cut needs a little more sanding. |

| Painting the models. |

| Close up of model paint drying. |

| I made this packer stick to pack the greensand in the mould box. |

| Here its drying after painting the up side. I made it by turning down a round handle on half of a 1-3/8" square stick. |

| Here the sand is spread out over the plastic and the kitty litter spread across it. |

| Begin mixing by pulling each corner, or pairs of corners up and toward the center, leaving a pile in the center. |

| Spread it back out and then pull up the corners to make a pile again. Several itterations of this does a good job of mixing the sand and kitty liter. |

| After straining out the lumps. |

| Here are the lumps etc I strained out. |

| After adding a little more water, it stays in a clump when you squeeze it. |

| It breaks smoothly and stays in clumps. |

| Here are the models laying on the bottom board and the mould frame around them. I sprinkled some talcum powder to act as a mould release. The mould form is made of 1x2s and must be very square. |

| Now I spread green sand on top and start packing (tamping) it down. |

| All packed but its not even with the top. |

| So I add more green sand and begin to pack again. |

| Now its packed and above the edge of the frame. |

| Now the top is flat and level with the edge of the form. |

| I place another board on top and turn the whole mould over. |

| I tap on each model then place a screw in the hole I drilled previously, wiggle it gently to remove the model from the sand. |

| Heres what the mould looks like after removing the model. |

| Weights in mould after pouring. |

| Not very pretty but they only have to be heavy. |

| Ditto. I'll probably screw the weights into the base so I'll drill a hole, but later I'll try casting a screw hole (once I get better at this). |