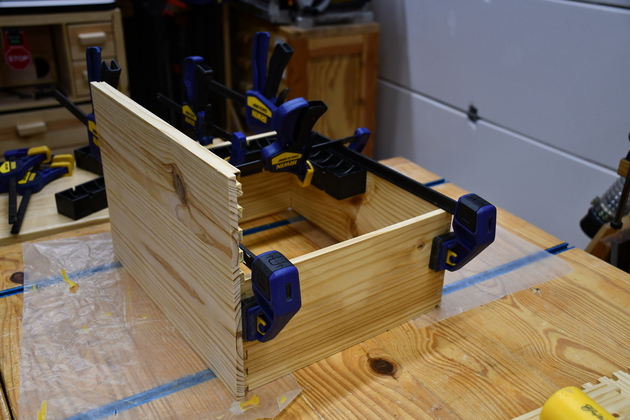

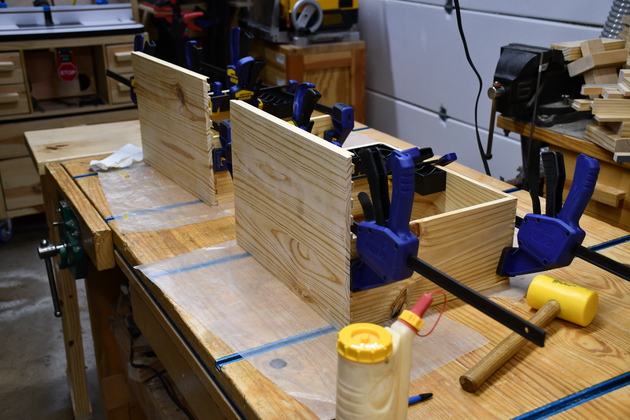

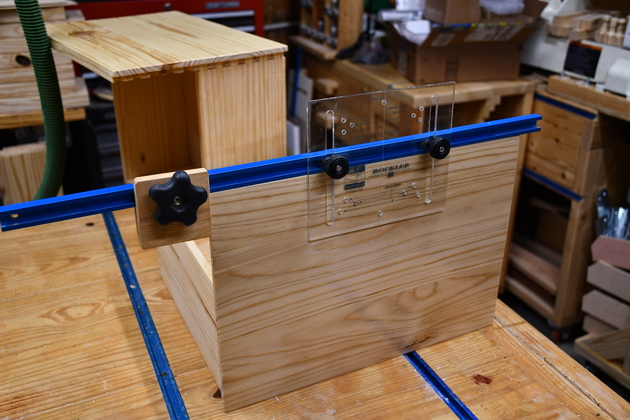

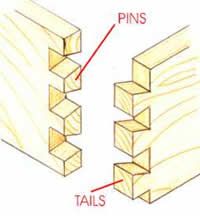

The corners of the drawer frames will be joined with dovetails. Dovetails have two parts that fit together, pins and tails shown in this pic. These cuts interlock and when glued form a very tight stable corner joint. I'm cutting half blind dovetails, that is, the tails (drawer's side) don't go all the way through the tail pieces (drawer's front and back) so you can't see the ends of the dovetails from the back or front of the drawer. Only on the drawer's side can you see the interlocking pieces.