|

|

|

Inset Panels

| |

|

|

|

Inset Panels

| |

| Laminated Panels. | Plugging Knot Holes. |

When I make framed panels (like cabinet sides or drawer fronts) I Like to use pine because I like knots and because the inset panel takes paint/stain the same as the frame.

| Resawing 1x6s for Pine Panel Faces. |

| Pile of 1/8" thick panel faces. These will be edge joined then laminated to 3/16" plywood. |

| Just a little bead of glue along one edge of the 1/8" panel. |

| Pine face being edge joined. |

| When you edge join the thin panels increase the pressure until you see a little squeeze out all along the joint. It doesn't take much pressure to edge join these. |

| I use some weight to keep the thin panel from buckling. |

| One of the pine face joints after gluing and before sanding. |

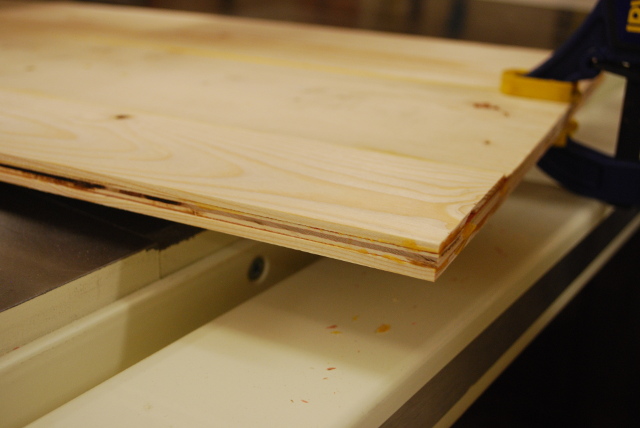

| Laminating pine face to plywood core. The little wedges on top of some of the pressure boards insures equal pressure on all parts of the panel being laminated. |

| A little bit of squeeze-out. |

| A double faced panel being set up in the laminating press. The objective is to keep all the pine face flush with each other to make a flat face. |

| Double faced panel after laminating. |