Tight Corner Bending Tool

I needed a tool to bend aluminum belt clips.

Bending this thing from a flat piece of aluminum is a challenge, the tightest

curves are about 5/16" across. The original was difficult to bend and showed it.

I came upon the idea of two parallel steel rods about the diameter of the curve

and spaced apart about the thickness of the aluminum as a bending form.

I bought two 5/16" carriage bolts 6" long, cut off the heads and thread then

welded them together using the old heads to keep them spaced and alligned.

I thought if I wanted the curves a little tighter, next time I might try one

1/4" and one 5/16" carriage bolts, so I can make some bends tighter than others.

The Bender

Bending this thing from a flat piece of aluminum is a challenge, the tightest

curves are about 5/16" across. The original was difficult to bend and showed it.

I came upon the idea of two parallel steel rods about the diameter of the curve

and spaced apart about the thickness of the aluminum as a bending form.

I bought two 5/16" carriage bolts 6" long, cut off the heads and thread then

welded them together using the old heads to keep them spaced and alligned.

I thought if I wanted the curves a little tighter, next time I might try one

1/4" and one 5/16" carriage bolts, so I can make some bends tighter than others.

The Bender

|

Here it is, clamped in the vise, as I use it. You can see part of one of the

original bolt heads just inside the vise jaws. The rods (bolts) should be

parallel and spaced so that the metal your bending will fit between.

|

|

A 1-3/4" wide aluminum strip, 1/16" thick, and about 7" long, chamfered and ready to bend.

|

|

All lined up on the tool ready to bend. Before I started bending, I used a

try square and drew a perpendicular line across the strip at the point I want

the bend to start. This helped me to keep the bends square.

|

|

Making a bend.

|

|

View from a different angle.

|

|

First bend complete.

Note: this bracket is for another sunglass case (Betty's) which attaches differently, but it shows how I made and use the bracket.

|

|

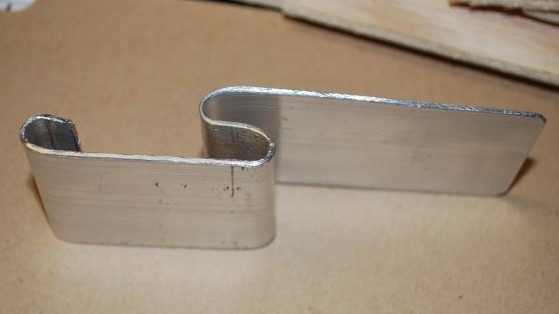

My bracket after it was bent.

BTW, this is 1/16" aluminum, I bought a 2"x2" aluminum angle and sawed the pieces I needed.

|

Bending this thing from a flat piece of aluminum is a challenge, the tightest curves are about 5/16" across. The original was difficult to bend and showed it. I came upon the idea of two parallel steel rods about the diameter of the curve and spaced apart about the thickness of the aluminum as a bending form. I bought two 5/16" carriage bolts 6" long, cut off the heads and thread then welded them together using the old heads to keep them spaced and alligned. I thought if I wanted the curves a little tighter, next time I might try one 1/4" and one 5/16" carriage bolts, so I can make some bends tighter than others.