|

Loading the 357 Sig

| ||

I load the 357 Sig on my RCBS Turret press using five positions in the turret. The turret press saves the loader time by having pre-set dies on a turret which may be quickly replaced to change calibers (changing the setting on the powder measure takes as much or more time as the rest of the caliber conversion). I call this semi-pregressive loading, I pick up a case, prime it in a hand primer, place it in the shellholder, and all other loading steps are done by just rotating the turret between ram strokes. I found that the fewer times I had to pick up a case, the faster I went. Look at my loading bench for layout of the loading area, it greatly facilitates hand movements for more speed.

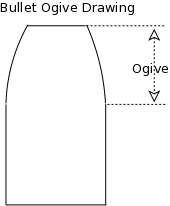

I Choose bullets for the 357SIG carefully, they must have a short ogive (the curved part at the front of the bullet). Please see ogive diagram. Note: there is only .150" case neck to hold the bullet in place so a taper crimp is mandatory.

I have never been able to make the primer attachement on the RCBS Turret press work correctly, so I use the RCBS Universal Hand Primer before placing each case in the shellholder. This can be counted as 1 and 1/2 handling of the case since I don't completely take my hand off during priming.

I don't like to lube cases (being spoiled by carbide dies for other calibers) and currently there are no economical carbide resizing dies available for the 357 Sig, however, I have found a way to load them without lubricating the cases.

Resizing is done in two steps plus the LEE FCD (Factory Crimip Die): first I use a Lee carbide .40 resizer deprimer die after tumbling and before ultrasonic cleaning which resizes the larger .40 part of the case

Second is the RCBS 357Sig steel resizer during loading which resizes the case neck.

The Lee Factory Crimp Die for the 357SIG also resizes the whole case.

Note: As stated in many places you don't want to tumble deprimed cases, if you can help it, since the corn cob media will frequently plug the flash hole.

|

I use the following dies to load 357Sig:

| ||

| Lee | .40 | Carbide Sizer/Deprimer |

| RCBS | .357SIG | Sizer |

| Hornady/RCBS | 9mm | Powder Drop/expander |

| RCBS | .357SIG | Seater |

| Lee | .357SIG | Factory Crimp |

For Pics of this sequence, please see the Turret Loading Sequence

Clean, Deprime, and Resize:

Please see Case Prep for details of cleaning, depriming, and sizing.

In this step I deprime and resize using a Lee .40 cal carbide sizer die (eliminating case lube and clean).

A second resize must be done during reloading, below.

This is an excellent time to examine the cases.

Prime:

The first loading step is to prime the case using the RCBS universal hand priming tool.

I pick up a clean unprimed case from the loading shelf (just below and to the left of my press), insert it into the hand primer, prime it, remove it from the primer and into the shellholder just above see loading bench details or 9mm loading sequence.

Resize (again):

I resize again during loading using the RCBS 357 resizer with decap pin removed and the resizer ball adjusted about .25" from the bottom of the die.

This appears to be a "sweet spot" since the case will be more difficult to extract the case from the die if the ball is too high.

The sizer ball in the 357 sizer die leaves the case about .354 and you need a little flare to allow the bullet to sit as it travels up into the seater die.

The case will be expanded in the next step.

I cycle the ram with my right hand then move the turret with my left.

Flare and Charge:

Charge the case using the Hornady Quick Change Powder Die with the Hornady case activated powder drop system and an RCBS Uniflow Powder Measure.

A Hornady .355 powder through expander in the powder die flares the case about .002".

In a single stroke, the case is flared and charged.

As I cycle the ram with my right hand, I pick up a bullet with my left.

Seat the bullet:

Place the bullet on top of the case (with my left hand) as you rotate the turret (with your right hand) to the RCBS 357 Sig seater die, then seat the bullet.

I like the RCBS seater because I can get a variety of seater plugs for different shaped bullets.

Apparently, other mfgrs. don't offer special seater plugs.

After I cycle the ram with my right hand, I reach across with my left and move the turret.

Crimp the bullet:

Last but not least use the Lee Factory Crimp Die for the 357 Sig.

Check the OAL with your dial caliper.

Drop the case into the Wilson 357 Sig case length gage (you have to pick the case gage up so the cartridge will bottom in the gage on it's shoulder.

If the case fits, drop it in the ammo box, its ready to fire.

Place the new round in the ammo box

As I pick up the finished round and place it in the ammo box with my left hand I rotate the turret back the the RCBS 357 sizer die.

So far I have loaded several thousand rounds of 357 Sig this way and have had no problems. I have loaded Rainier 100 gn .380 FMJ RN and Montana Gold 125 gn FMJ FP. I have purchased some Speer 125 gn GDHP and the RCBS seater plug for them, but haven't loaded any yet.