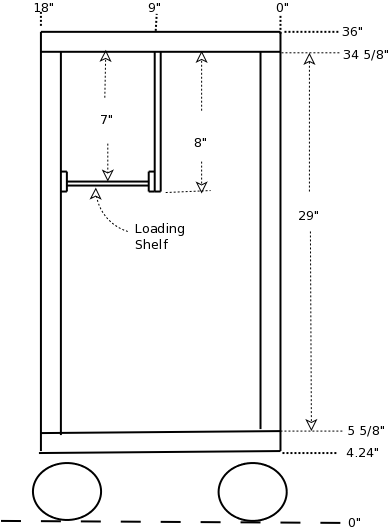

Diagrams of a Mobile Loading Bench With Planed Frame

10/07/13: Tweak positions and sizes for printing. Add diagram click (hyper) links.

Break into 3 pages for printing.

05/19/13: Add main bay floor brace to diagrams.

05/18/13: Tweak lumber list, panel cut list needs work UNDER CONSTRUCTION

05/02/13: Add Purchase and Cut Lists

05/01/13: Spun off from Non-Planed Diagram.

To the Diagrams,

to the Purchase List,

to the Cut List.

A 2x4, when it comes from the mill is 3-1/2" wide and 1-1/2" thick and has slightly rounded corners.

For this project I'll plane about 1/16" off each board face so the 2x has nice square corners (See Square Board Page for more info) and the joints will be flush.

The resultant 2x4s will be 3-3/8" by 1-3/8".

The bench top is made from 2x6s edge laminated so I end up with a 1-1/2" thick top, 18" wide and 36" long.

All joints use biscuits every 4 inches on the center line of the boards being joined.

You have to keep everything square and plumb so drawers work.

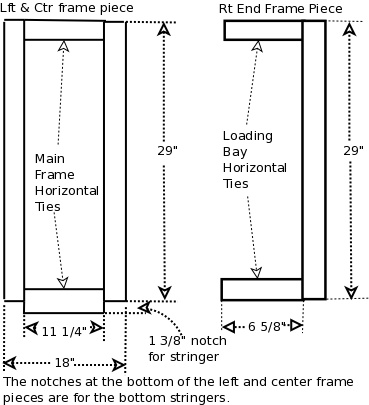

Passing the 2x4s across the jointer I still hold the 10" from the end dimension of the right vertical support so the loading bay is 10" deep.

Planing with a jointer makes the drawers about 1/4" wider.

I take 1/16" off each side (2 cuts of 1/32" off each side), reducing the width and thickness by 1/8", so I have to increase the lengths of the horizontal braces in the vertical frame pieces by 1/4" to compensate.

Drawers are 5" high, 16" deep, and 26 1/8" wide to fit into a 26 1/4" wide space.

The drawer front is a 1x6 cut down to 5" high, 26 1/8" wide with a 1/2" rabbet on each end to conceal the slides.

The sides and back are 1x4s resawn and joined on the sawn side leaving about 5/16" thick and sides are 16" long, back is 26 1/8" wide.

I allow 1/16" on each side of a drawer, and at least 1/8" vertical clearance between drawers, and top drawer and frame.

If you are not careful with measurements and cutting, you may want to allow more clearance for the drawers.

I always put the guide 1" from the bottom of the drawer, so, since each drawer is 5" high, I measure down 4 1/8" from the top, draw a horizontal line and mount the cabinet side of the drawer guide on this center line.

Then another 5 1/8" down to the next drawer guide center line (and any additional drawers I add).

Here is a link to how I make drawers and handles

The loading shelf and the vertical frame for it is made from 1/2" plywood, usually birch.

Loading shelf and slide diagram.

Square Board Page.

Purchase List.

Depot Hardware Purchase List.

Lumber Purchase List.

Rockler Hardware Purchase List.

Cut List.

1/2" Plywood Layout.

Diagrams

All these diagrams are .png format, you can save them on your computer then display with Firefox and print them.

Or click on the image for a single page with the image on it.

|

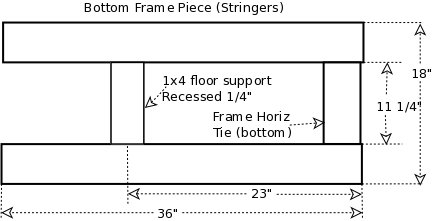

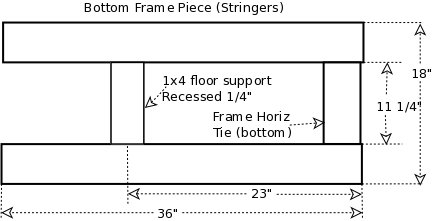

Bottom Frame Piece (Stringers).

Click on the image for a single page with the image on it.

|