10/08/14: Page Origin.

I occasionally need to make a lot of semi-circular holes in the edge of a board, like bottle racks or gouge drawer separators.

I have found an easy way to do this is to clamp the piece onto my drill press and use a hole saw to cut the hole.

I made this little jig to help.

My drill press (Jet 17" JDP-17DX) has tee tracks built into it's work table which make this easy to accomplish, otherwise you'll have to clamp the jig to your drill press table.

When I make wine racks or glass supports, I do a lot of hole sawing on the drill press.

Since these cuts are partial circles there is a lot of pressure against the work piece, to one side.

The problem is aligning and securing the piece being sawed, I originally used two clamps to hold down the work piece and made extra marks to align the cut for each notch.

This is a very time consuming process, so I decided to make a jig to speed things up.

I got a pair of large "Push Clamps" from Rockler because they are much faster.

Since the "Push Clamps" center of pressure is 3/4" above their base and I wanted to hold a 3/4" thick work piece, I had to raise the work piece 3/8&qot; so the clamps pushed in the vertical center of the wood.

If the work piece is narrow, I use another 1x2 push block to clamp against.

I cut a base of 3/4" plywood the same width as the table on my drill press, and 12-1/2" front to back.

Then I laminated a 3/8" piece of plywood, the width of the base and 6" front to back, to the back of the base.

I added two 1x2s as a fence, and since the hole saw is round, I cut the corners off the back side of the fence pieces, leaving about a 1/2" edge in front.

Next I drew a center line, front to back then a fence line 3" from the minimum extension of the "Push Clamps" and glued two pieces of 1x2 to each side, forming a fence.

When I saw the 1-1/2" thick bottle support bars I use a 1x2 push block with a center line all the way around it.

I make alignmet ticks, indicating the center of the notch, on the bottom of the support bars.

I also use this to saw glass support pieces for wine glass racks.

Click for larger Pic

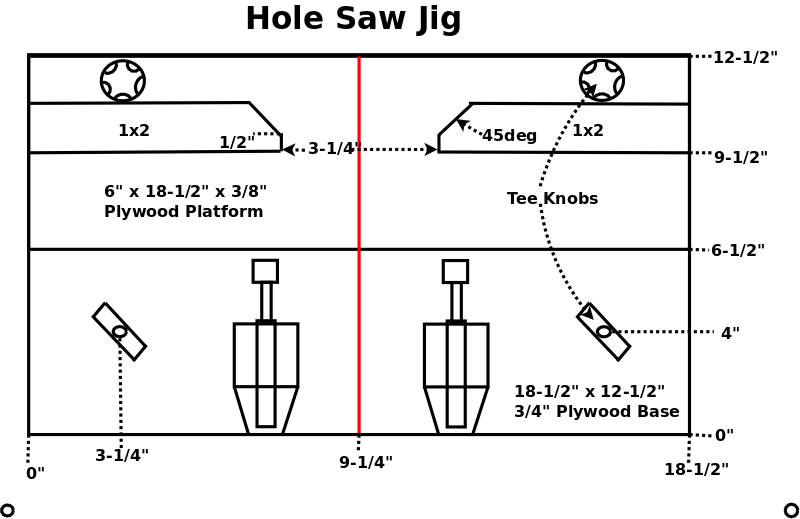

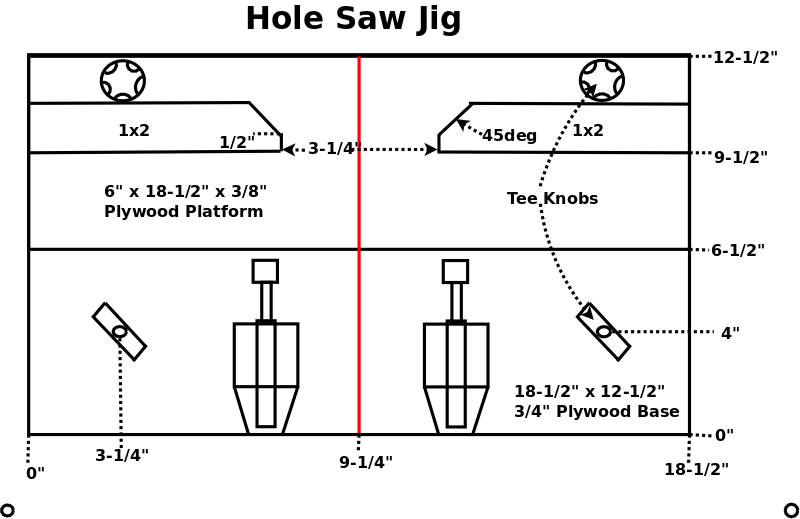

About the Diagram

The red line is the center line, you always line up your hole saw and work piece on this line.

The jig can be moved forward and backward so the edge of the hole saw is the correct depth of cut you want.

The drawing is symmetrical, that is, the tee knobs are the same dist from each edge.

The tee knobs will have to be positioned according to the tee slots in your drill press table.

|

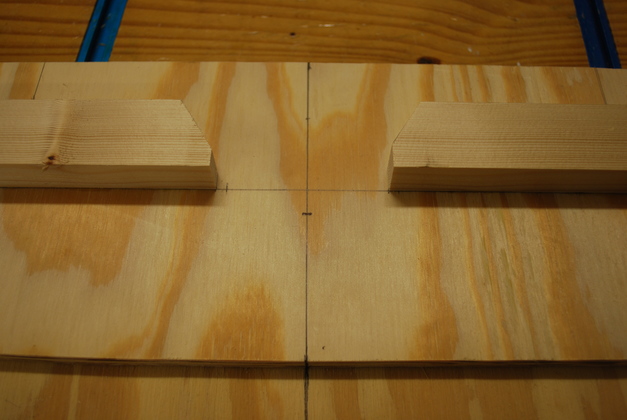

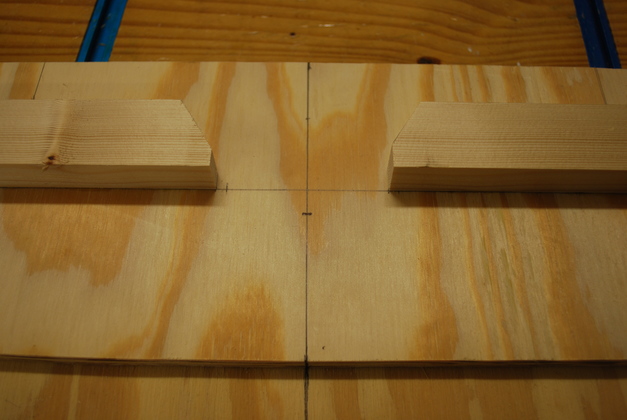

Here I'm laminating the 3/8" plywood on top of the 3/4" base.

|

|

The base with the 3/8" plywood platform laminated at the back.

The center of the Rockler push clamps is 3/4" above the base and I want to saw 3/4" pieces so I added a 3/8" platform to raise the sawed piece so the push clamp is pushing in it's center.

|

|

Front quarter view showing relative thickness.

|

|

The bar clamped on top is holding pressure on the two fence bars.

|

|

Base with fence bars glued on.

|

|

Closer look showing center line, fence line and 1/2" mark.

|

|

Here it is with tee bolts and push clamps installed.

|

|

Bottom showing the tee bolts.

|

|

The jig unmounted.

|

|

Side view.

You can see where I have sawn various size holes.

|

|

One push clamp extended the other pulled back.

|

|

Sawing a bottle support bar.

You can just make out the center line on the jig aligned with the line all the way around the push block.

The two "Push Clamps" are loose and the push block is not quite against the bottle support bar so you can see all the alignment marks.

|

|

Closer look, you can see the line all the way around the push block and the tick mark on the bottom of the bottle support bar.

These "tick marks" are the only marking I have to do on the bottle support bars.

The push block is also aligned with the center line on the jig.

|

|

Here the "Push Clamps" are tight, ready to saw.

The 3/8" platform raises the push piece so the clamp is pushing against it's center.

|

|

Sawing a 4-1/8" notch, I only saw out a 1/2" deep notch from the support bar leaving a full inch to support the bottles.

|

|

Sawing a 1-5/8" notch for a bottle neck.

|

|

Front quarter view.

|

|

Expanded Hole saw Jig, capable of sawing a 6" hole and a 1" hole.

Note the 3 pieces, the original (shortened), a vertical bar clamp and the back end with push type clamps.

|

|

Side view.

|

|

After the first try, I realized I needed something to keep the push bar vertical, so two more tee bolts and knobs.

|