|

|

|

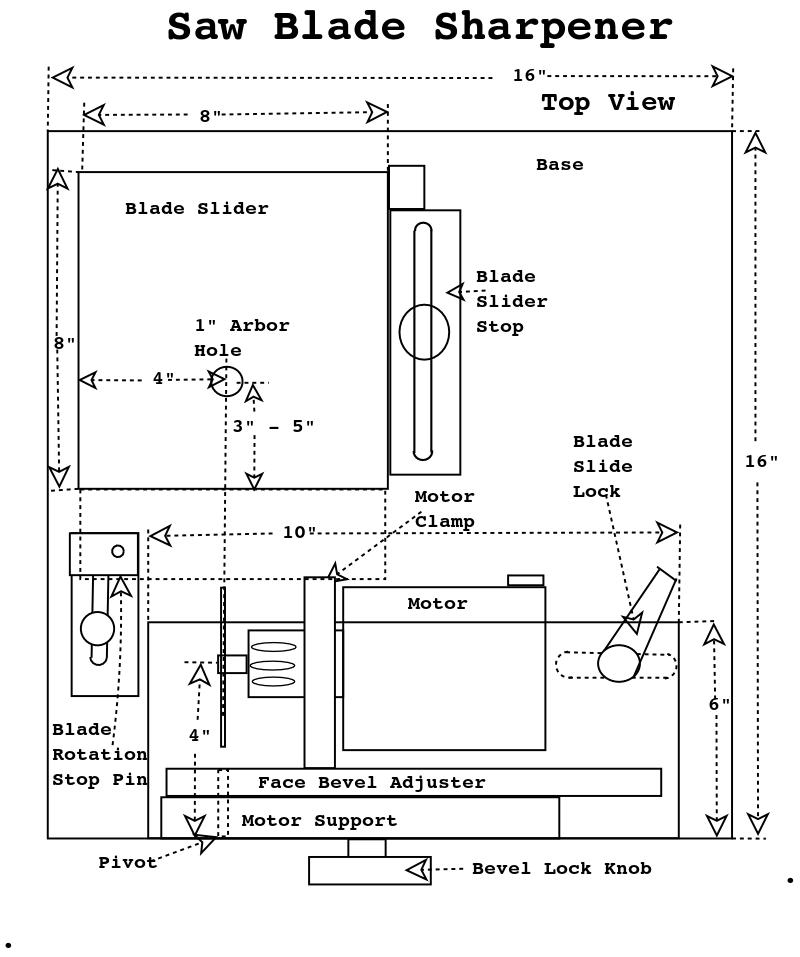

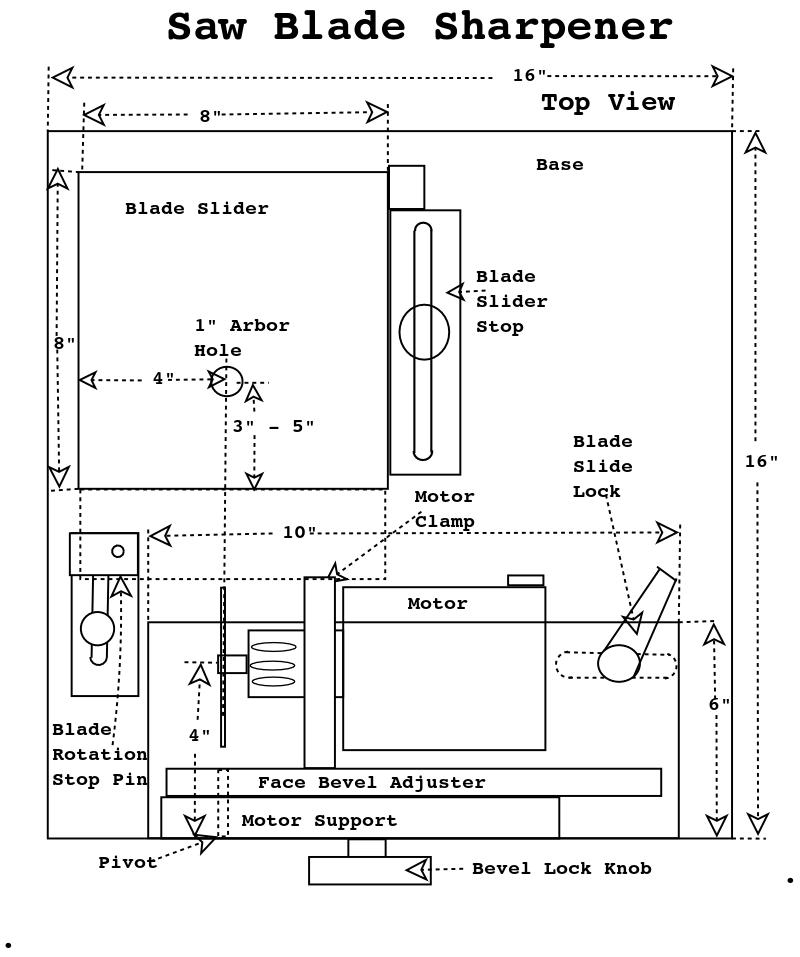

Blade Sharpener

| |||

| Harbor Freight Original | Diagram | Build Info | Sharpen Info |

| Big Diag | Motor Slider |

Several Years ago I bought a Harbor Freight saw blade sharpener, but it had so much play in the motor guides that the blade could move 1/32", it was impossible to sharpen a decent blade! The HF bushings that slid along the guide rods for the motor support were sloppy as all getout, at least on the unit I have. I only tried to sharpen one blade, the slop was there out-of-the-box. I have 6 or 8 good blades that are a little dull so I need them sharpened.

Recently, I have noticed a lot of DIY blade sharpeners on the web and think I will take a shot at making one from the stable parts of the Harbor Freight unit, based on some of these ideas. The HF unit moved the motor in and out to grind each tooth face and angled the motor for face bevel. The DIY units move the blade to the sharpener, the only movement in the motor is to change it's angle.

MF 126 made-in-china AKA WINTER Kreissägeblatt-Schärfmaschine SBS 8-70, BestEquip Round Circular Saw Blade Grinder Machine 110 on Amazon. Looked great, I first saw David Gladden demonstrate the chinese version, then the German version.

I plan to rotate the blade (moving the motor in and to) to accomodate for hook and rotate the grinder motor (blade) to accomodate for face bevel.

The maximum hook on these blades if 20°.

My blades run from 7-1/4" to 10".

Some of the 10" blades have a alternate 30° top bevel and a ±18&seg; hook.

To accomodate a ±20° hook the cutter blade must be able to move at least 1.7" either side of the center of the blade.

So, if I have 4" total side to side it should accomodate the maximum hook in either direction.

The maximum face bevel is ±25°, the adjustment slot is 3" from the fulcrum so the slot must be 2.8" high.

Freud LU88s have a 15° rake(Hook) and a 15° alternate top bevel.

Ranges: Hook= ±20°, Bevel= 30°

I'm going to build the motor slider 1st and check it for stability and overall dimensions.

|

|

|

|

|

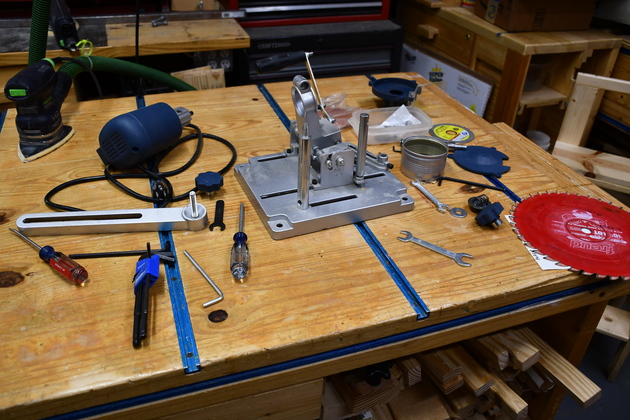

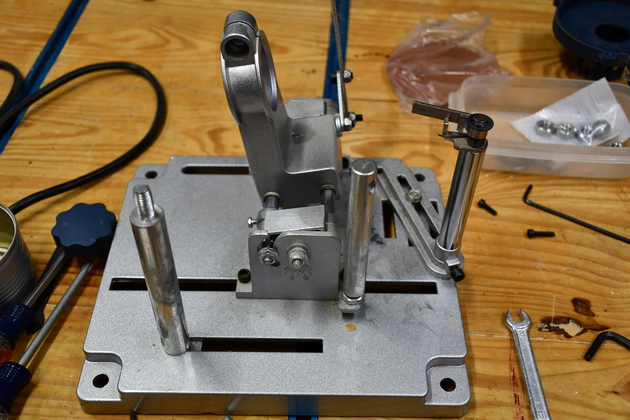

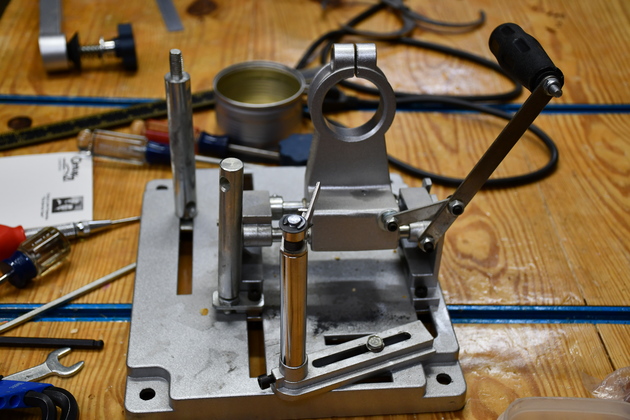

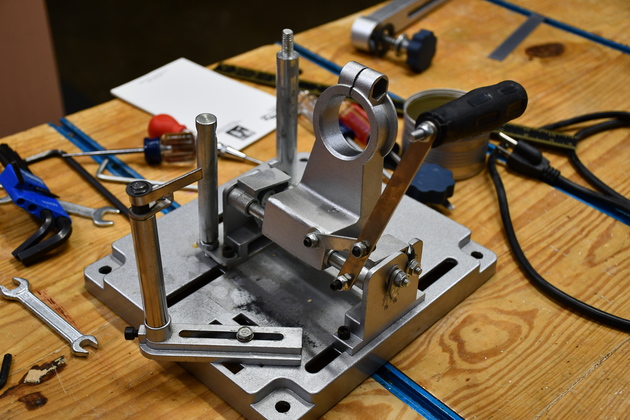

Partially disassembled on my workbench. |

|

The nice looking HF motor with a rocker switch, I plan to use this in the redesign. Note the housing tapers toward the output shaft. |

|

Look from the shaft end, note the motor's cross section is oblong/oval. But there is an area on the neck of the shaft housing that is flat, thats where the HF unit clamped on. |

|

Blade holder orig. Note the cone shaped recess. |

|

Blade holder with spring loaded centering cone, spring, washers, and knob. |

|

Blade index in closed postion. |

|

Blade index in open position. |

|

The base plate and motor carrier, from the front. |

|

Base from the right side. |

|

Base from right rear quarter. |

|

|