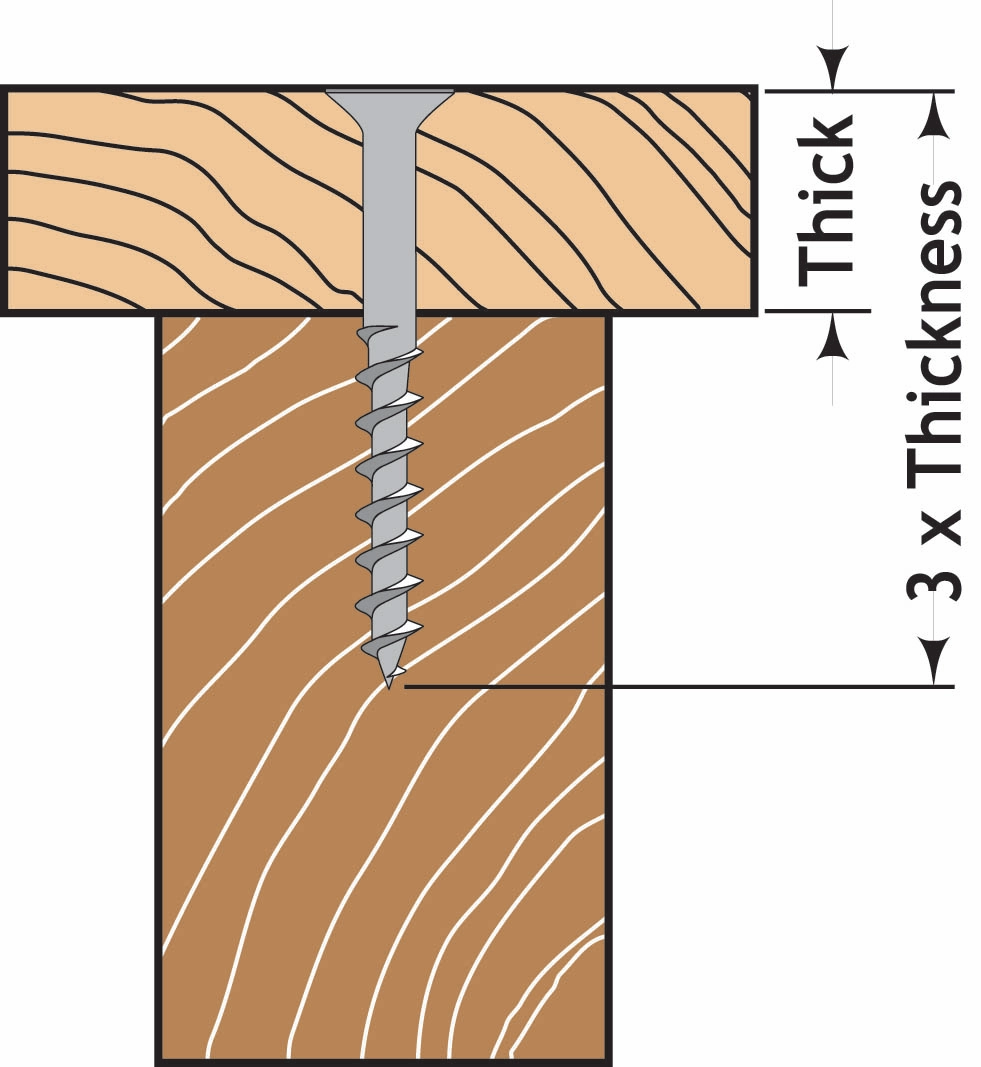

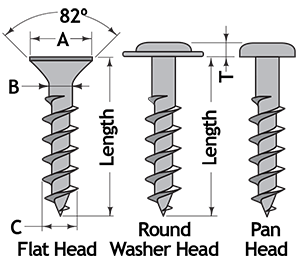

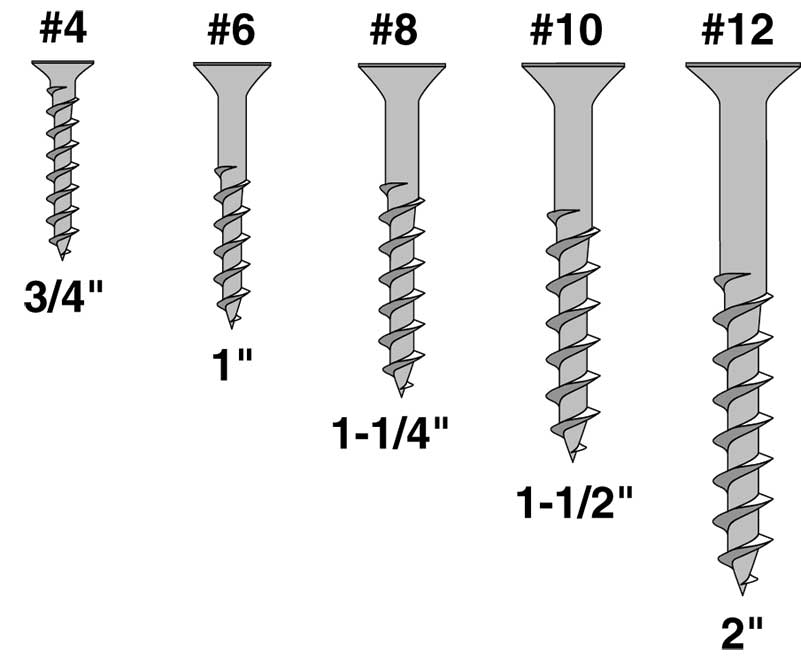

Not sure which size you need? The drawings below are as accurate

as possible to help in deciding which size is required for

your job. In addition, the following guidelines may

help you select the proper size:

|

|

| Driver Bit Color Codes | ||

| Screw Size | Driver Size | Hand Driver Color (normally) |

|---|---|---|

| #4 | #0 Bit | Light Yellow |

| #5, 6, 7 | #1 Bit | Medium Green |

| #8, 9, 10 | #2 Bit | Red |

| #12, 14 | #3 Bit | Black |

| #5/16 in. & up | #4 Bit | Un–coded; |

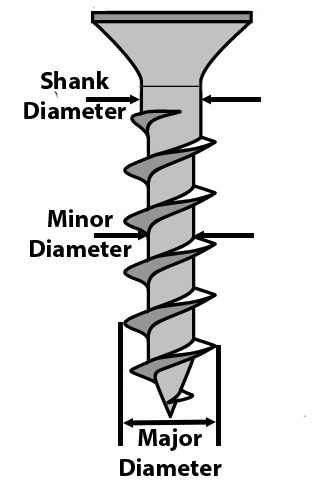

#10 General construction, heavy-duty furniture, outdoor projects, decks, lawn furniture, boat building, etc. Available in 3/4 in. to 4 in. lengths.

#12 & #14 For heavy-duty construction, hanging solid-core doors, etc. Available in 3/4 in.to 6 in. lengths in selected styles. (#12 shown).