Reciprocating Pumps

From: https://housing.com/news/what-is-a-reciprocating-pump/

Reciprocating pump: Parts, advantages and disadvantages

When a precise amount of fluid is required for delivery, reciprocating pumps are

used.

A reciprocating pump converts mechanical energy into hydraulic energy. It does

it by sucking liquid inside a stationary cylinder using thrust, a piston or a

plunger. Reciprocating pumps are also called positive displacement pumps or

piston pumps because of the use of a piston or plunger during pumping.

The delivery pressure of this pump is usually quite significant, and a small

quantity of liquid is handled. If maintained and handled with care, reciprocating

pumps last for a few decades. However, they can be lost to wear and tear if

subjected to carelessness.

A reciprocating pump converts mechanical energy into hydraulic energy. It does

it by sucking liquid inside a stationary cylinder using thrust, a piston or a

plunger. Reciprocating pumps are also called positive displacement pumps or

piston pumps because of the use of a piston or plunger during pumping.

The delivery pressure of this pump is usually quite significant, and a small

quantity of liquid is handled. If maintained and handled with care, reciprocating

pumps last for a few decades. However, they can be lost to wear and tear if

subjected to carelessness.

Source: Pinterest

Table of Contents

Source: Pinterest

Table of Contents

Reciprocating pump: Parts

The parts of the reciprocating pump include:

- Cylinder

The piston inside the cylinder moves to and fro, and the piston obtains

moment through the help of a connecting rod, connecting the piston and

crank.

- Piston and piston rod

To start the suction, the piston inside the cylinder moves back, while for

liquid discharge, the piston is moved to the forward section. The function

of the piston rod is to move the piston in a linear direction, either

forward or backwards.

- Suction pipe

The reciprocating pump’s suction pipe collects water from the water sump.

It then sends the water to the cylinder with the help of a suction valve.

Therefore, the suction pipe is responsible for allowing water to flow inside

the cylinder.

-

Suction valve

The suction valve is referred to as the non-return valve, found on the

suction pipe inlet. The water flows by entering the suction pipe into the

cylinder but cannot send it back. Hence, the flow in this valve is

unidirectional. The valve only opens when there is the suction of fluid and

closes when it discharges towards the outside.

- Water sump

As the name suggests, the water sump is the water source for the cylinder or

pump. The water gets transported towards the delivery pipes through the use

of pistons from this very water sump.

- Strainer

The strainer is located at the end of the suction pipe and plays a very

important role in separating the solids from the water or liquid. It also

acts as a mesh used to separate dirt, dust particles, or other obstructions

from the water released. Without the presence of the filter, all kinds of

dirt or dust may enter the water in the cylinder, further resulting in it

jamming the area and stopping the smooth working of the pump.

Source: Pinterest

known about the self priming pump

Source: Pinterest

known about the self priming pump

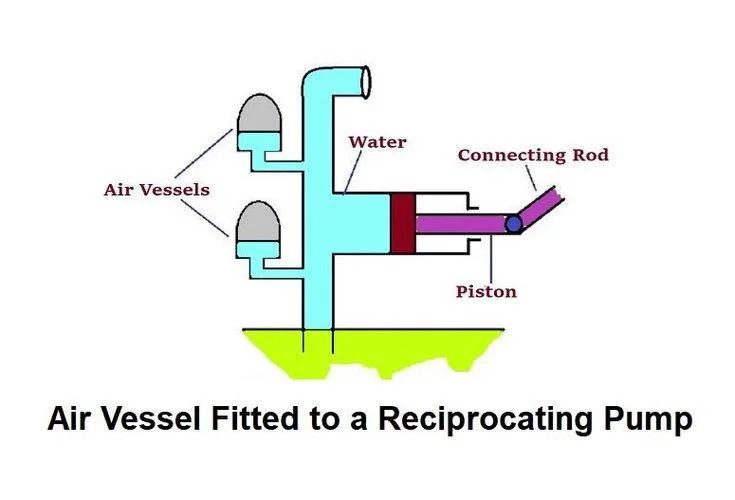

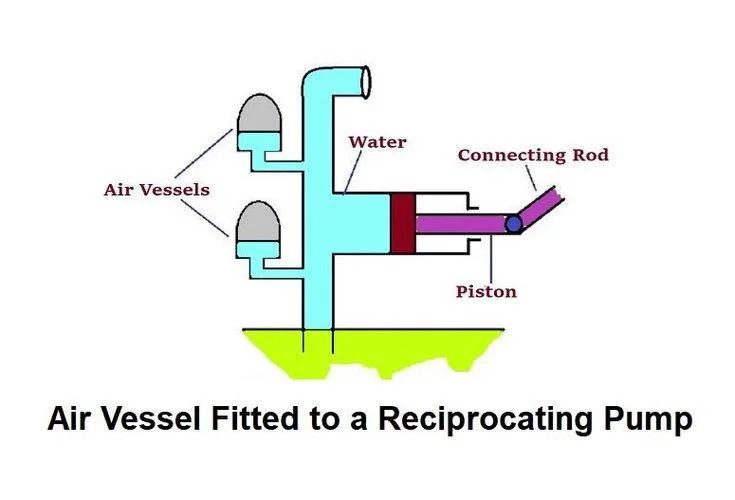

- Air vessels

The air vessel refers to a closed chamber constructed out of cast iron and

has two ends. One of the ends stays open at the base of the cylinder through

which the liquid is flown into the vessel cylinder. To get a uniform

discharge, air vessels are fitted in the pump’s suction pipe and delivery

pipe. The air vessels also work to reduce the amount of effort that is put

in to overcome the frictional resistance in the delivery or suction pipe.

Another function of the air vessels is to make sure that the pump runs at

high speed along with separation.

- Crank and connecting rod

The crank is connected to a power source, such as the engine or motor, for

rotation to take place. It is shaped into a circular disc. On the other

hand, the connecting rod is placed as a medium between the crank and the

piston used to convert rotary motion into linear motion.

Delivery pipe

The task of the delivery pipe is to move water from the desired location to

another. This pipe transfers water from the cylinder itself. It also

connects the pump cylinder to the discharge outlet.

Delivery valve

Similar to the suction valve, this valve is also known as a non-return

valve. It is used for the discharge of water from the cylinder to the

delivery pipe. When suction is in practice, the delivery valve is closed due

to suction. When a discharge is in action, the suction valve remains closed,

and the delivery valve is opened to transfer water.

Types of reciprocating pump

- 1)Single-acting reciprocating pump

In this type of reciprocating pump, there is a cylinder, inside which there

is a piston designed to move forward or backwards. This piston reciprocates

with the help of rods connecting the piston and the rotating crank. In turn,

this crank rotates with an electric motor’s help. On the rotation of this

crank, the first stroke by the piston is made, referred to as the suction

stroke, and then the water is entered into the cylinder.

When the suction stroke starts, the crank rotates from an angle of 0° to

180°, which is A to C, and the piston then starts moving towards the right

side of the cylinder. As a result of this process, the vacuum gets created,

causing the valve to then open, therefore, allowing the water to enter the

cylinder.

After this happens, the next stroke is delivered, known as the delivery

stroke, during which the cylinder releases the water. During this stroke,

the crank rotates back from C to A, which is a degree of 180 degrees to 360

degrees, and the piston then starts moving towards the left side of the

cylinder.

As a result, inside the cylinder, the pressure of the liquid keeps

increasing. This pressure then results in the suction walls closing and the

delivery valve, on the other hand, opening. As a result, the water is then

pushed into the delivery pipe, raising it to the needed level.

Source: Pinterest

Source: Pinterest

- 2) Double-acting reciprocating pump

In this kind of reciprocating pump, the requirements are two delivery pipes

and two suction pipes. Unlike the single-acting reciprocating pump, the suction

stroke and delivery stroke happen simultaneously but only at different sides of

the piston.

Therefore, to complete one reciprocation of the crank, two delivery strokes

are needed, after which the water is transferred to the pipe using the pump.

See also: Types of building materials

Other types of lesser-known reciprocating pumps are:

- Pump with air vessel

- Pump without air vessel.

- Single cylinder

- Double cylinder

- Triple cylinder pump.

How reciprocating pumps work

When the crank is connected to the power source and a motor, it starts

rotating, putting the connecting rod and crank into movement. Following

this, the piston, which is attached to the connecting rod, will start moving

in a linear direction. The piston moves to the right when the crack moves

outwards, creating a vacuum inside the cylinder, further leading the suction

valve to open. As a result of this process, the water from the source gets

sucked into the cylinder with the help of the suction pipe.

On the other hand, the piston moves to the left when the crank starts moving

inwards of the cylinder, putting pressure on the liquid or water in the

cylinder. This results in the generation of pressure, which further causes

the delivery valve to open and allows the liquid to flow through the

delivery pipe.

When the piston finally reaches the extreme left position, all the water in

the cylinder is then pushed through the help of the delivery valve. The

crank then spins outwards, resulting in the piston moving to the right to

create suction. This process keeps on repeating for the working of the

reciprocating pump.

How is the reciprocating pump different from the centrifugal pump?

- A reciprocating pump is a positive displacement type pump built on the

principle of movement of the piston in either forward or backward directions. On

the other hand, a centrifugal pump uses the impeller’s kinetic energy to supply

liquid from one destination to another.

- The centrifugal pump is comparatively easier to construct, has less weight,

provides more durability, has less maintenance cost, and can run at a higher

speed. However, the centrifugal pump also has low efficiency. The reciprocating

pump, on the contrary, has more complications in its construction, has more

weight, requires a lot more maintenance to ensure no wear and tear, has high

maintenance costs, and cannot run at a higher speed.

- While reciprocating pumps are considered to be suitable for fewer

charges with higher heads, centrifugal pumps are suitable for opposites,

that is, large discharges with the help of small heads. It is also notable

that reciprocating pumps cannot handle dirty water and require more floor

space than centrifugal pumps.

- Reciprocating pumps require air vessels to function and are also

complicated to operate in comparison to centrifugal pumps, which only need

priming and do not require air vessels. Operating the centrifugal pumps are

also comparatively easier than the reciprocating pumps.

Reciprocating pump: Where is it used?

- Reciprocating pumps can be used in oil drilling operations and are the

primary choice for light oil pumping.

- They have also been said to be helpful for pneumatic pressure pumps and

are also used to feed small boilers.

- One can also find reciprocating pumps in high-pressure pumps that are

used for the rivers’ osmosis system, hydro testing of tank vessels, and

various others.

- These pumps are also used to clean several elements, including sewer

line cleaning, vehicle cleaning, wastewater treatment system, and more.

Advantages and disadvantages of reciprocating pumps

- These machines can deliver the desired flow rate with high preciseness

while maintaining a continuous discharge rate.

- Reciprocating pumps also deliver fluids at high pressures, and no

priming is required for these kinds of pumps.

- The efficiency of a reciprocating pump is at least 10% to 20% greater

than that of a centrifugal pump.

- The capital cost of these pumps is extremely high. Other than that, the

flow rate of these pumps is also low.

- Reciprocating pumps cannot pump viscous liquids, and the maintenance

charges of these pumps are extremely high due to the large number of parts

associated with them.

FAQs

What is meant by reciprocating action?

Reciprocating action is referred to as simply the act of reciprocating. It

means to do something that is a response to a specific action as

corresponding or equivalent to the previous action.

What is a reciprocating pump used for?

Reciprocating pumps are used when a precise amount of fluid is required for

delivery. The pumps are also used when the delivery pressure is supposed to

be higher than what can be acquired through other types.

Which one of the centrifugal and reciprocating

actions is better?

Both of them have their advantages, with centrifugal being the cheaper

option and reciprocating being the option with more complications. However,

it depends on the kind of area that they will be working in to define which

one is better.

A reciprocating pump converts mechanical energy into hydraulic energy. It does

it by sucking liquid inside a stationary cylinder using thrust, a piston or a

plunger. Reciprocating pumps are also called positive displacement pumps or

piston pumps because of the use of a piston or plunger during pumping.

The delivery pressure of this pump is usually quite significant, and a small

quantity of liquid is handled. If maintained and handled with care, reciprocating

pumps last for a few decades. However, they can be lost to wear and tear if

subjected to carelessness.

A reciprocating pump converts mechanical energy into hydraulic energy. It does

it by sucking liquid inside a stationary cylinder using thrust, a piston or a

plunger. Reciprocating pumps are also called positive displacement pumps or

piston pumps because of the use of a piston or plunger during pumping.

The delivery pressure of this pump is usually quite significant, and a small

quantity of liquid is handled. If maintained and handled with care, reciprocating

pumps last for a few decades. However, they can be lost to wear and tear if

subjected to carelessness.

Source: Pinterest

Table of Contents

Source: Pinterest

Table of Contents

Source: Pinterest

Source: Pinterest

Source: Pinterest

Source: Pinterest