SPI Tutorial for ESP8266

#include <SPI.h>

From: https://diyi0t.com/spi-tutorial-for-arduino-and-esp8266/

SPI Tutorial for Arduino and ESP8266

| In this tutorial we dive deeper into the Serial Peripheral Interface short SPI.

You learn the following parts:

Protocol Settings

Data Transmission

Advantages and Disadvantages

At the end of this tutorial you find two examples of the SPI communication between two Arduino microcontrollers and an Arduino and an ESP8266 based microcontroller.

|

|

SPI Thumbnail

|

|

| Table of Contents

|

| 1 | Comparison of Microcontroller Communication Protocols from the Viewpoint of SPI

| 2 | SPI Settings to Enable SPI Communication

| 2.1 | Clock Rate Setting for SPI

| 2.2 | Data Shifting Setting for SPI

| 2.3 | Modes of Transmission for SPI

| 3 | SPI Data Transmission

| 4 | SPI Advantages and Disadvantages

| 5 | Examples of SPI Communication

| 5.1 | SPI communication: Arduino Uno to Arduino Mega

| 5.2 | SPI communication: ESP8266 NodeMCU to Arduino Uno

| 6 | View and Decode SPI Communication with an Oscilloscope

| | | | | | | | | | |

Comparison of Microcontroller Communication Protocols

from the Viewpoint of SPI

SPI was invented by Motorola in 1970. The following table compares the

communication protocols I2C, SPI and UART based on different categories.

| | Description | I2C | SPI | UART

|

| Invented by | | 1982 by Philips Semiconductor | 1970 by Motorola | 1960 by Gordon Bell at Digital Equipment Corporation

|

| Synchronous data transfer | A clock line is required to synchronize the

communication | True | True | False

|

| Asynchronous data transfer | Instead of a clock signal the data steam itself contain start and stop signals | False | False | True

|

| Throughput | | 10,000 to 1,000,000 bits/s | Up to 10,000,000 bits/s | Up to 115,200 bits/s

|

| Slave need unique address | | True | False | False

|

| Number of pins required | | 2 | 4 | 2

|

| Error checking protocol | | True | False | True

|

| Multi-master | You can have multiple masters controlling one or multiple slaves | True | False | False

|

| Multi-slave | You can connect multiple salves to a single master | True | True | False

|

| Packet-switched | The transferred data is grouped in packages / messages, made of a header and a payload | True | False | False

|

| Single-ended | The data is transferred by a single wire | True

Serial Data (SDA) False

|

Master in Slave Out (MISO)

|

Master Out Slave In (MOSI) False

|

| Serial connection | Data is transferred bit by bit along a single wire | True | True | True

|

Like I2C, SPI is a synchronous serial data protocol and therefore need a clock

to synchronize the communication between master and slave devices.

SPI is recommended when the communication speed needs to bet very fast. The

maximal throughput is up to 10,000,000 bits/s and much faster than I2C and UART.

The speed which can be used by the microcontroller is based on the chip rate

(clock rate). Most Arduino microcontroller have a chip rate of 16 MHz but it is

recommend to set the communication speed to ½ of the chip rate 8 MHz

(8,000,000 bits/s). The ESP8266 has a higher chip rate compared to the Arduino

microcontroller with 80 MHz and it is recommended to reduce the communication

speed for the ESP8266 microcontroller too.

To set the SPI clock relative to the system clock you use the function

setClockDivider(). For example if you want to have a SPI throughput of 8 Mbits/s

and your chip rate is 16 MHz you use the following function with the parameter

setClockDivider(SPI_CLOCK_DIV2). The following dividers are

available: 2, 4, 8, 16, 32, 64 or 128.

But in practice it is up to you if you want to select the communication speed

manually via the function, because the Arduino selects the communication speed

automatically equal or less than the setting based on the device with the

lowest communication speed.

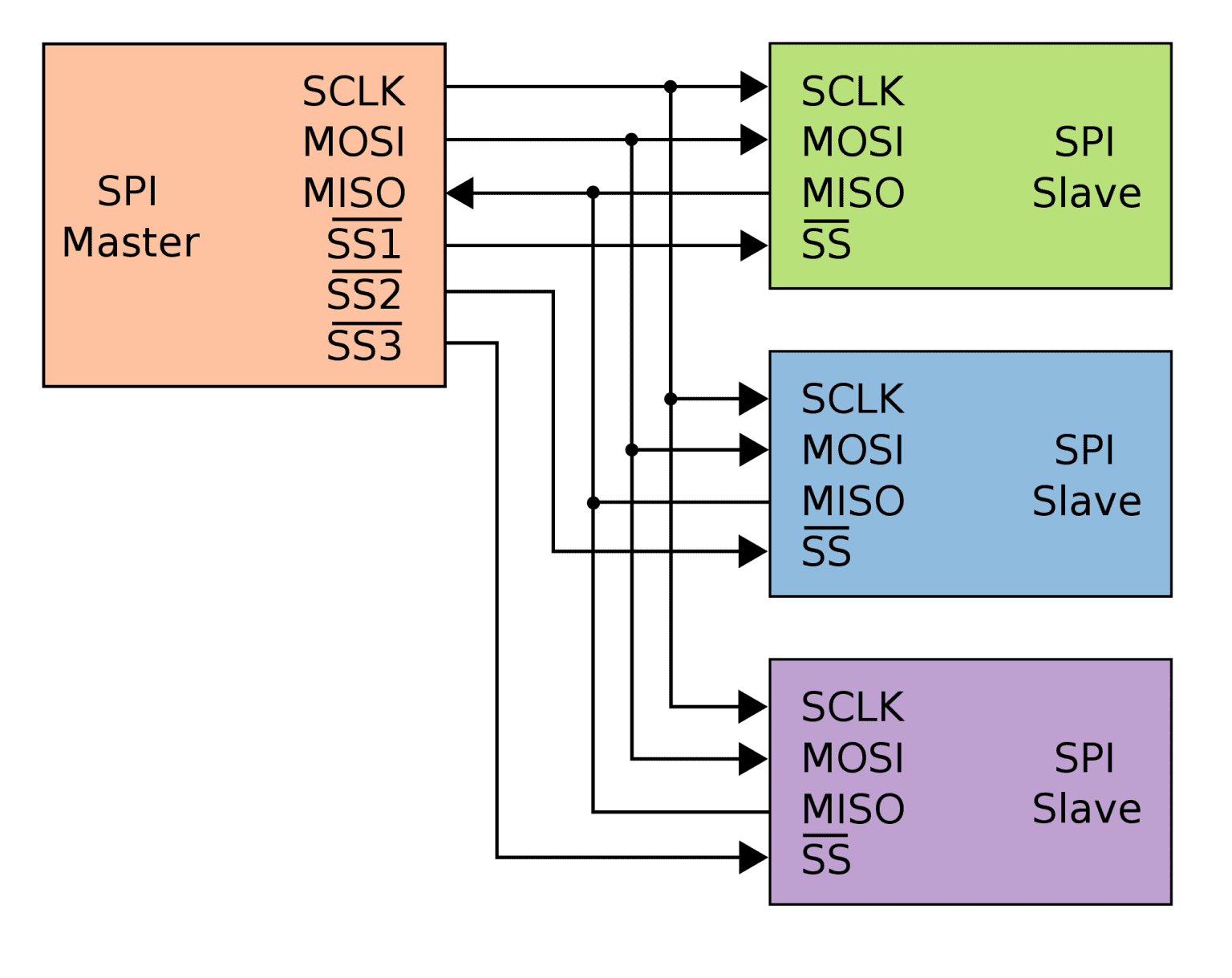

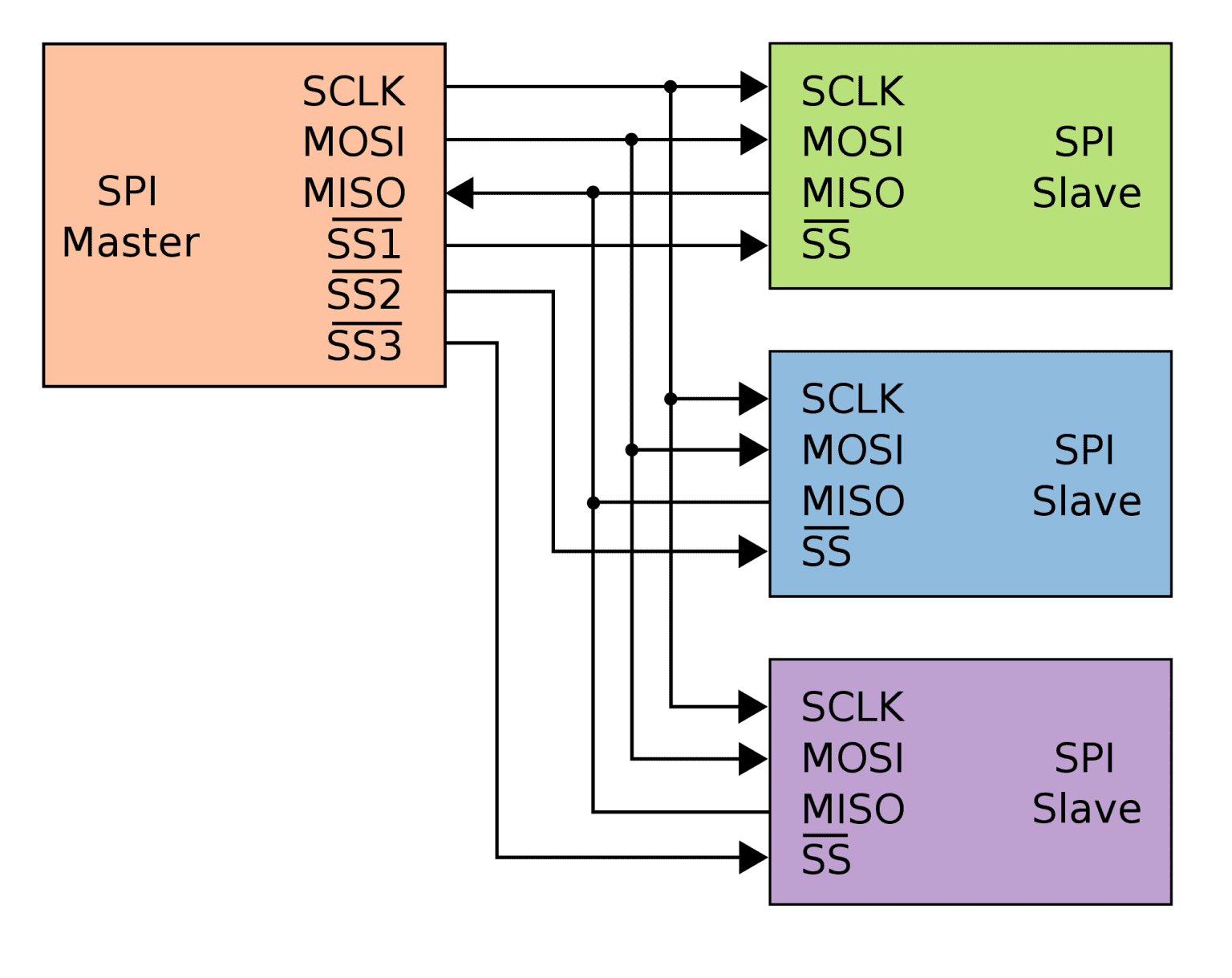

In a SPI system you always have only 1 master device. Therefore SPI is not able

to build a multi-master system. If you want to communicate between for example

an Arduino Uno and a NodeMCU, one device has to be the master and the other one

the slave. But SPI is able to handle multiple slave devices, each one connected

to the master device via the so called Slave Select (SS) line. Because the Slave

Select line connects each slave with the master there is no unique address for

each slave like for the I2C communication.

SPI three slaves

Source Picture:

There are 3 lines which connect the master device to all slave devices

MISO (Master in Slave Out): The Slave line for sending data to the master

MOSI (Master Out Slave In): The Master line for sending data to the peripherals

SCK/SCLK (Serial Clock): The pulse from the master device to synchronize

data transmission

And 1 line from the master to each device

SS (Slave Select) One specific line to each peripheral that the master can

enable or disable the specific slave. This allows to share the MISO, MOSI and

SCK line between multiple devices. The SS pin can be any digital pin on your

microcontroller

SS Pin is LOW → Slave communication to master is enabled

SS Pin is HIGH → Slave communication to master is disabled

If you want to know what are the MISO, MOSI and SCK pins for different microcontrollers, you find this information in the related pinout articles: Arduino Mega, Arduino Uno, Arduino Nano, ESP8266 NodeMCU or better if you download the Microcontroller Datasheet eBook.

Microcontroller Datasheet eBook

The 35 pages Microcontroller Datasheet Playbook contains the most useful information of 14 Arduino, ESP8266 and ESP32 microcontroller boards.

Get more Information

SPI three slaves

Source Picture:

There are 3 lines which connect the master device to all slave devices

MISO (Master in Slave Out): The Slave line for sending data to the master

MOSI (Master Out Slave In): The Master line for sending data to the peripherals

SCK/SCLK (Serial Clock): The pulse from the master device to synchronize

data transmission

And 1 line from the master to each device

SS (Slave Select) One specific line to each peripheral that the master can

enable or disable the specific slave. This allows to share the MISO, MOSI and

SCK line between multiple devices. The SS pin can be any digital pin on your

microcontroller

SS Pin is LOW → Slave communication to master is enabled

SS Pin is HIGH → Slave communication to master is disabled

If you want to know what are the MISO, MOSI and SCK pins for different microcontrollers, you find this information in the related pinout articles: Arduino Mega, Arduino Uno, Arduino Nano, ESP8266 NodeMCU or better if you download the Microcontroller Datasheet eBook.

Microcontroller Datasheet eBook

The 35 pages Microcontroller Datasheet Playbook contains the most useful information of 14 Arduino, ESP8266 and ESP32 microcontroller boards.

Get more Information

SPI Settings to Enable SPI Communication

If we want to start a communication, we first have to enable SPI with the

following Arduino code SPI.beginTransaction(SPISettings(8000000, MSBFIRST,

SPI_MODE0));

You see that when staring a SPI communication there are in total 3 settings

which can be set if we want to control the settings manually. These SPI setting

are not deleted when SPI communication is disabled with SPI.endTransaction().

Instead you can change the SPI settings by overwrite the settings via the

function SPISettings(). There is always the option to let the microcontroller

set the SPI settings automatically which we see in the examples in this

tutorial.

Clock Rate Setting for SPI

The first setting is the SPI clock rate which is set to 8 Mbits/s in this example.

Data Shifting Setting for SPI

The second setting is the data shifting which defines which bit is transferred

first. There are 2 options:

Most Significant Bit (MSB) → MSBFIRST: Bit 8 is the first bit which is transferred via SPI

Last Significant Bit (LSB) → LSBFIRST: Bit 1 is the first bit which is transferred via SPI

Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

2⁷ 2⁶ 2⁵ 2⁴ 2³ 2² 2¹ 2⁰

MSB > 1 1 0 0 1 0 1 1 < LSB

Most SPI chips use MSB first data order.

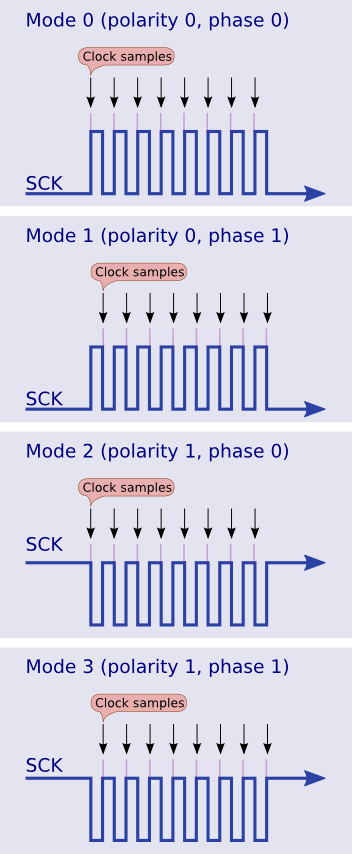

Modes of Transmission for SPI

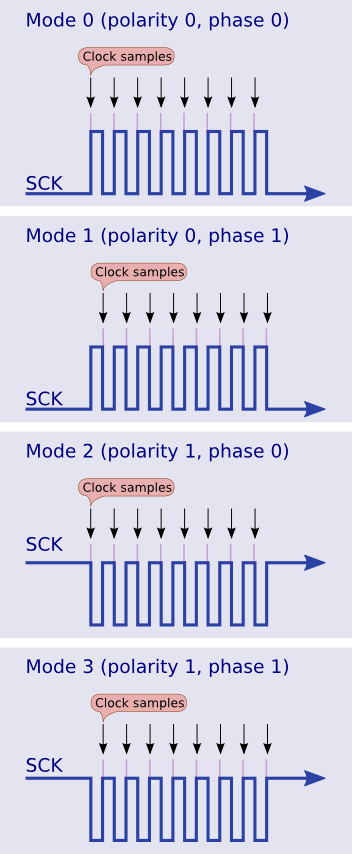

There are in total 4 different modes of transmission depending on the combination of 2 transmission settings:

Clock Phase (CPHA)

CPHA=1: Samples of the rising edge of clock pulse

CPHA=0: Samples of the falling edge of clock pulse

Clock Polarity (CPOL)

Clock idle when high (CPOL=1): Each cycle consists of a pulse of 0. The

leading edge is a falling edge and the tailing edge is a rising e

dge.

Clock idle when low (CPOL=0): Each cycle consists of a pulse of 1. The

leading edge is a rising edge and the tailing edge is a falling edge.

The following table shows the 4 different modes of transmission.

| Mode | Clock Polarity (CPOL) | Clock Phase (CPHA) | Output Edge | Data Capture

|

| SPI_MODE0 | 0 | 0 | Falling | Rising

|

| SPI_MODE1 | 0 | 1 | Rising | Falling

|

| SPI_MODE2 | 1 | 0 | Rising | Falling

|

| SPI_MODE3 | 1 | 1 | Falling | Rising

|

For most devices SPI_MODE0 is the default mode of transmission. The following

pictures show the four different modes. You see the SCK line and when the clock

samples.

Modes of Transmission

Source Picture

Modes of Transmission

Source Picture

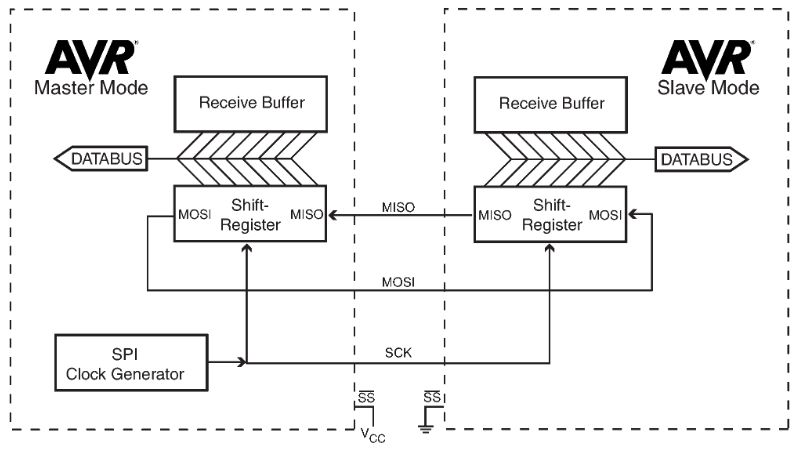

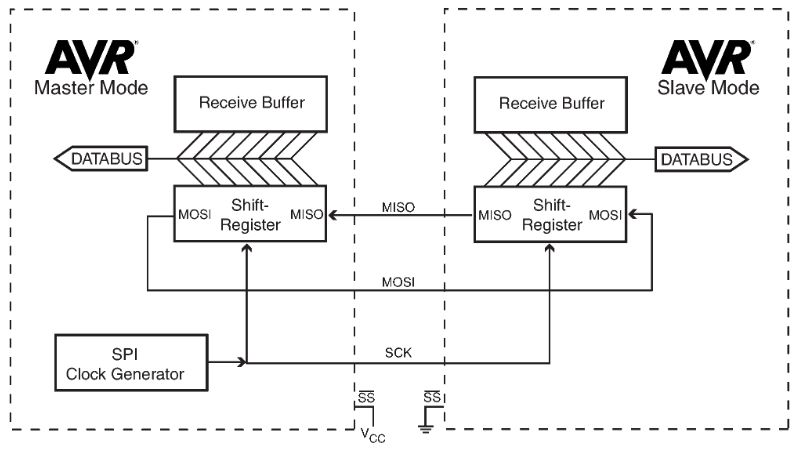

SPI Data Transmission

Source Picture

The data which is transferred via SPI communication is stored in 8-bit or 16-bit

shift registers which have the same length for the master and slave device. Data

is usually shifted out with the most significant bit first, defined by the SPI

settings and stored as the new last significant bit of the shift register. The

SPI module is unBuffered in the transmit direction and single Buffered in the

received direction. The following 6 steps describe the SPI data transmission:

First the master device configures the SPI settings (clock rate, data

shifting, mode of transmission).

The master selects the slave device by pulling the SS line LOW (from logical

1 to logical 0).

The following steps are done all at the same time during one clock cycle on

a full-duplex data transmission:

On the clock edge, the master sends the first bit to the slave via the

MOSI line. The slave reads the incoming message.

On the clock edge, the slave sends the first bit to the master via the

MISO line. The master reads the incoming message.

The data exchange is done, when the complete shift register is transmitted.

The whole shift register is then copied into the receive Buffer and the

shift registers are reloaded. The data transmission processes starts again.

If the transmission is complete, the master stops the clock signal and stops

pulling the SS line LOW.

Source Picture

The data which is transferred via SPI communication is stored in 8-bit or 16-bit

shift registers which have the same length for the master and slave device. Data

is usually shifted out with the most significant bit first, defined by the SPI

settings and stored as the new last significant bit of the shift register. The

SPI module is unBuffered in the transmit direction and single Buffered in the

received direction. The following 6 steps describe the SPI data transmission:

First the master device configures the SPI settings (clock rate, data

shifting, mode of transmission).

The master selects the slave device by pulling the SS line LOW (from logical

1 to logical 0).

The following steps are done all at the same time during one clock cycle on

a full-duplex data transmission:

On the clock edge, the master sends the first bit to the slave via the

MOSI line. The slave reads the incoming message.

On the clock edge, the slave sends the first bit to the master via the

MISO line. The master reads the incoming message.

The data exchange is done, when the complete shift register is transmitted.

The whole shift register is then copied into the receive Buffer and the

shift registers are reloaded. The data transmission processes starts again.

If the transmission is complete, the master stops the clock signal and stops

pulling the SS line LOW.

SPI Advantages and Disadvantages

Advantages

| Disadvantages

|

Full duplex communication (I2C is not synchronous communication)

Higher throughput than I2C

Not limited to 8-bit words

Lower power consumption than I2C because no pull up resistors are required

Slaves do not need a unique address compared to I2C

|

Requires more pins than I2C

No error checking protocol

Many different variants because no formal standard defined

|

Examples of SPI Communication

The following table gives you an overview of all components and parts that I

used for this tutorial. I get commissions for purchases made through links in

this table.

|

Component

|

Amazon Link

|

AliExpress Link

|

| Arduino Uno | Amazon | AliExpress

|

| Arduino Mega | Amazon | AliExpress

|

| ESP8266 NodeMCU | Amazon | AliExpress

|

| USB Oscilloscope | Amazon | AliExpress

|

I also give you two examples for the SPI communication because it is good to

know the theory and how something is working. But in the end you want to realize

projects and need examples to see how the SPI communication is done. The first

one is a communication between the Arduino Uno as master and an Arduino Mega as

slave. In the second example we build up a SPI communication between an ESP8266

NodeMCU as master and an Arduino Uno as slave.

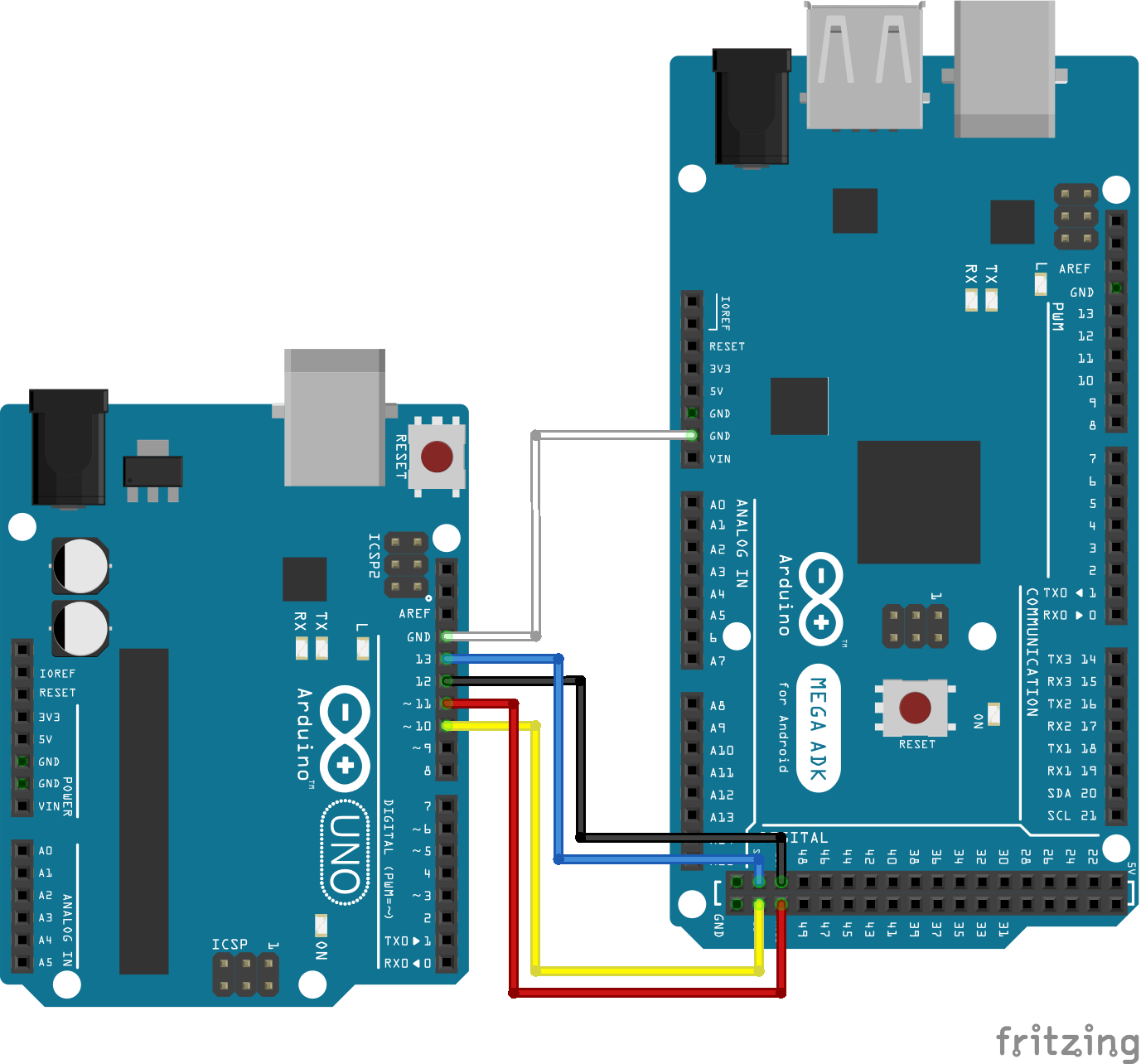

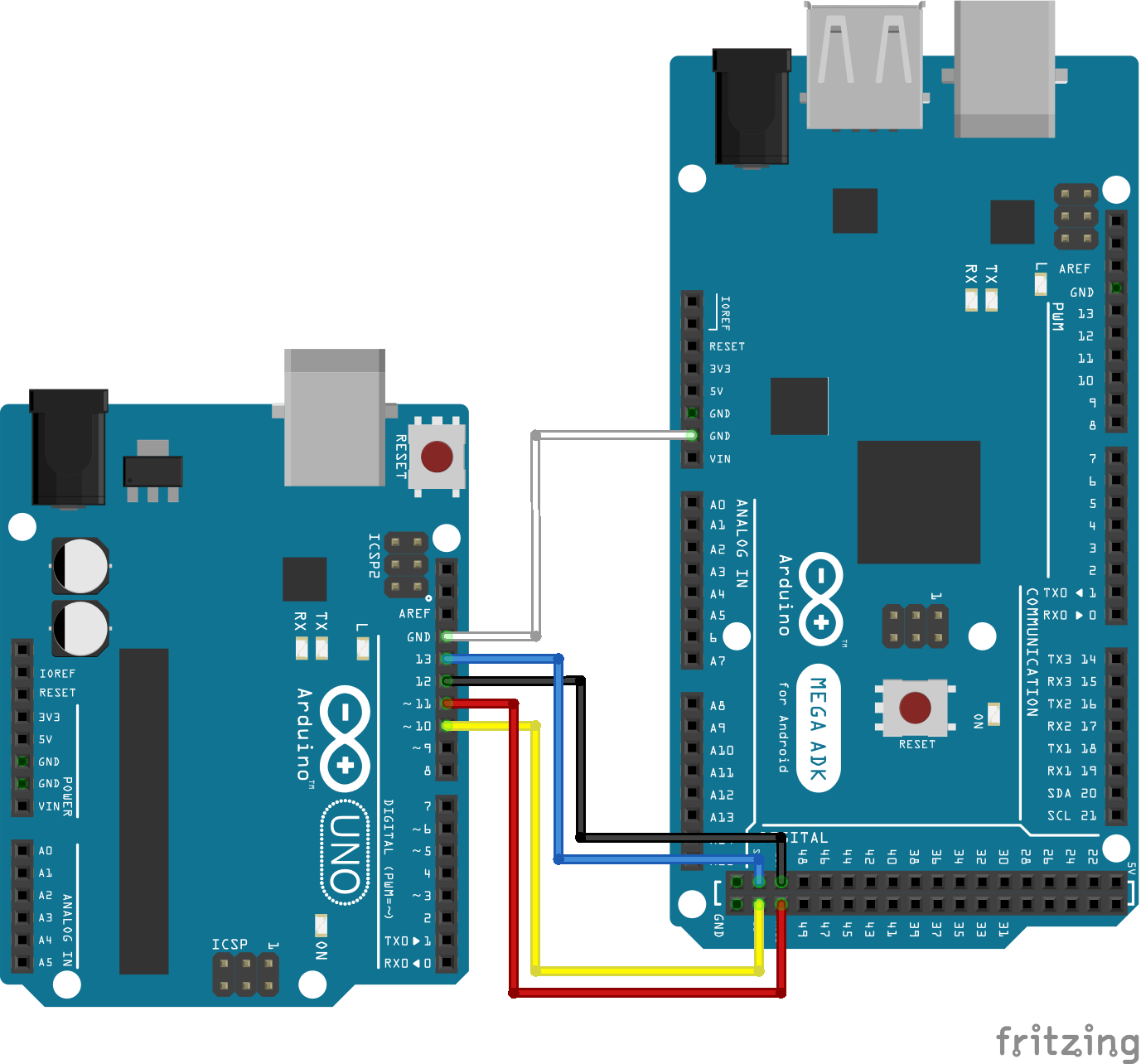

SPI communication: Arduino Uno to Arduino Mega

We want to communicate via SPI between an Arduino Uno as master and an Arduino

Mega as slave. The following picture shows you the wiring. You also find the

used pins in the pinout overview table in the special articles for the Arduino

Uno and Arduino Mega.

Arduino Uno 2 Mega

In the following part we go step by step through the program script.

Arduino Uno 2 Mega

In the following part we go step by step through the program script.

Script for the master device: Arduino Uno

/*F********************************************************************

*

**********************************************************************/

#include "SPI.h"

/*F********************************************************************

*

**********************************************************************/

void

setup()

{

digitalWrite( SS, HIGH ); // disable Slave Select

SPI.begin();

SPI.setClockDivider( SPI_CLOCK_DIV4 ); //divide the clock by 4

}

/*F********************************************************************

*

**********************************************************************/

void

loop()

{

char c;

digitalWrite( SS, LOW ); // enable Slave Select

for( const char * p = "Hello Mega\r" ; c = *p; p++)

SPI.transfer( c );

digitalWrite( SS, HIGH ); // disable Slave Select

delay( 2000 );

}

First we have to include the SPI library for our example. In the setup

function we first disable the slave select pin by pulling the SS line HIGH. Then

we initialize the SPI communication with the SPI.begin function. The last part

of the setup function is optional. We divide the clock by 4 to reduce the SPI

throughput from 16 MHz to 16/4=4 MHz.

The loop function starts with defining a character

variable c and enable the slave select line by pulling the line LOW. We want to

send the string “Hello Mega\r” and use the \r as flag to signal the slave device

that the character transfer is done. Therefore the string is split into its

letters in the for loop and transferred via SPI. When the transmission is

complete the slave select pin is disabled and we wait for 2 seconds until we

send the message from the master to the slave again.

Now you can upload the script for the Arduino Uno as master to the

microcontroller.

Script for the slave device: Arduino Mega

/*H********************************************************************

*

**********************************************************************/

#include "SPI.h"

//************************* DEFINES ************************************

#define BAUD 9600

//************************* PROTOTYPES ************************************

void ISR( SPI_STC_vect );

//************************* VARIABLES ************************************

char Buff[50];

volatile byte Indx;

volatile boolean Proc;

/*F********************************************************************

*

**********************************************************************/

void

setup( void )

{

Serial.begin( BAUD );

pinMode( MISO, OUTPUT); // HAVE TO SEND ON MASTER IN SO IT SET AS OUTPUT

SPCR |= _BV( SPE ); // TURN ON SPI IN SLAVE MODE

Indx = 0; // BUFFER EMPTY

Proc = false;

SPI.attachInterrupt(); // TURN ON INTERRUPT

}

/*F********************************************************************

*

**********************************************************************/

void

loop( void )

{

if( Proc)

{

Proc = false; //reset the Proc

Serial.println( Buff ); // PRINT ARRAY ON SERIAL MONITOR

Indx= 0; // RESET BUTTON TO ZERO

}

}

/*F********************************************************************

*

**********************************************************************/

ISR( SPI_STC_vect ) // SPI interrupt routine

{

byte c = SPDR; // READ BYTE FROM SPI DATA REGISTER

if( Indx < sizeof( Buff) )

{

Buff [Indx++] = c; // SAVE DATA IN THE NEXT INDEX IN THE ARRAY BUFF

if( c == '\r') // CHECK FOR THE END OF THE WORD

Proc = true;

}

}

The slave script starts also with the inclusion of the SPI library. Also we have

to define 3 variables. The Buff variables stores the incoming values via SPI.

The Indx variable stores the index of the 8 bit and the process variable saves

the current status of the transmission.

In the setup function, the baud rate is set to 9600 to view the SPI output in

the serial monitor. The MISO pin is set as output to receive the data from the

master. The SPI is set in slave mode and the two variables are set with their

default values. Also interrupts are enables for the SPI communication.

After the setup function the SPI interrupt routine is defined. First the SPI

data is read form the internal data register and stored in binary form. As long

as the Buffer is not completely filled with 50 characters, bit by bit is stored

into the Buffer from the SPI data register until the flag “\r” for the end of

the character is found. If the message is completely transmitted, the variable

process is set to TRUE.

The loop function waits until the process variable is TRUE and then first resets

the variable and print the complete Buffer on the serial monitor. The last part

is to reset the index of the Buffer to refill the Buffer from the beginning.

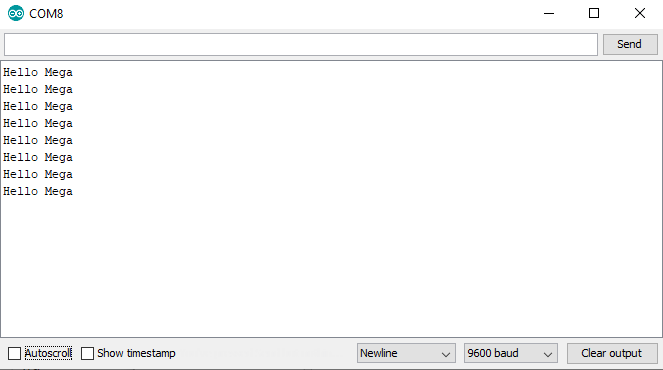

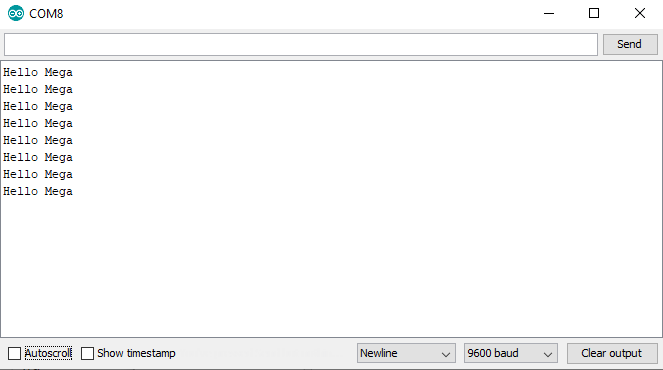

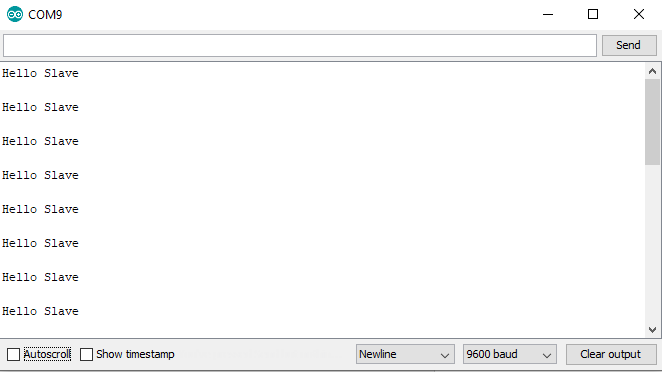

The following picture shows the serial output from the Arduino Mega as slave.

The word “Hello Mega” is transferred via SPI.

Arduino Uno 2 Mega Serial Monitor

Arduino Uno 2 Mega Serial Monitor

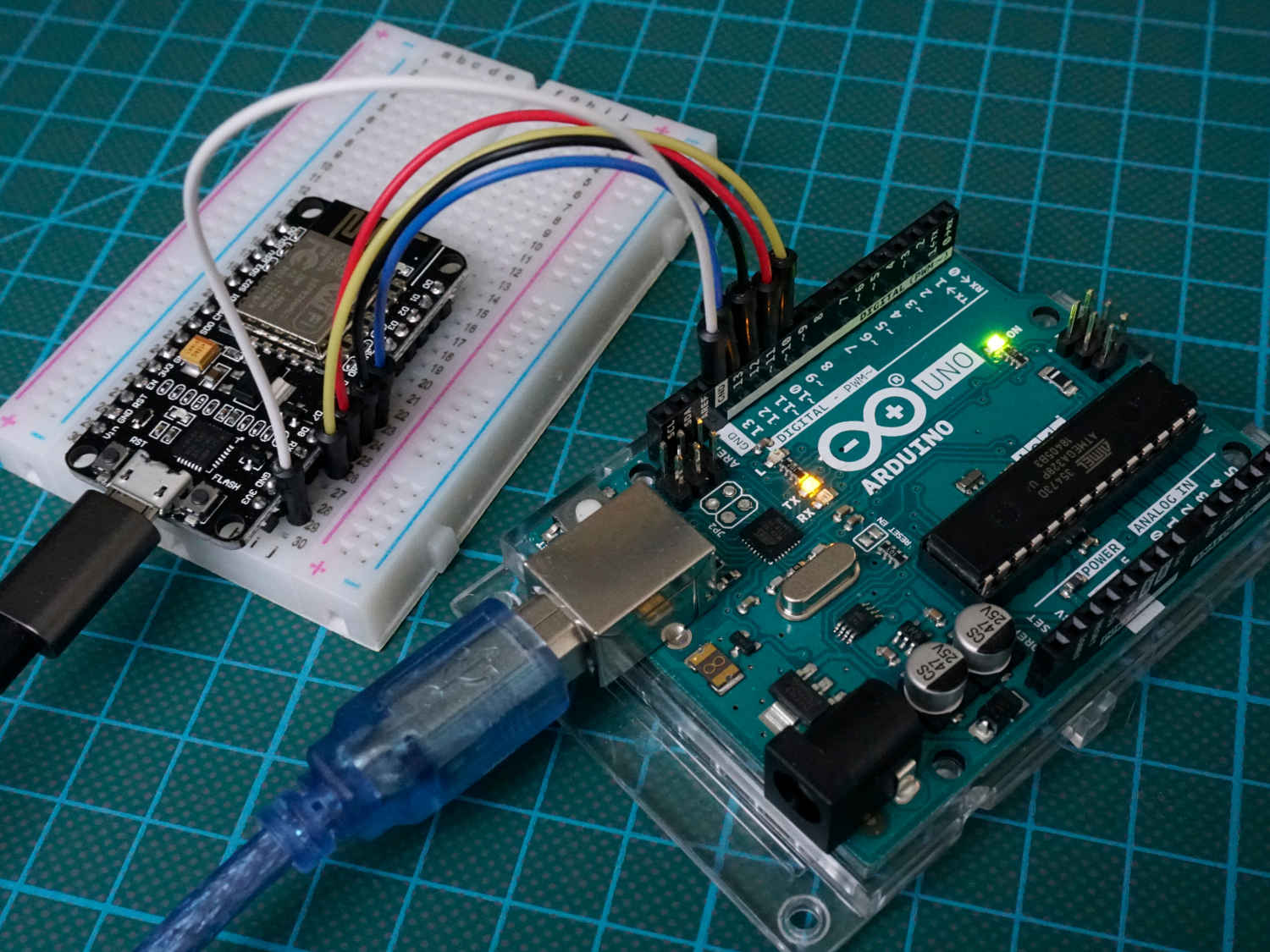

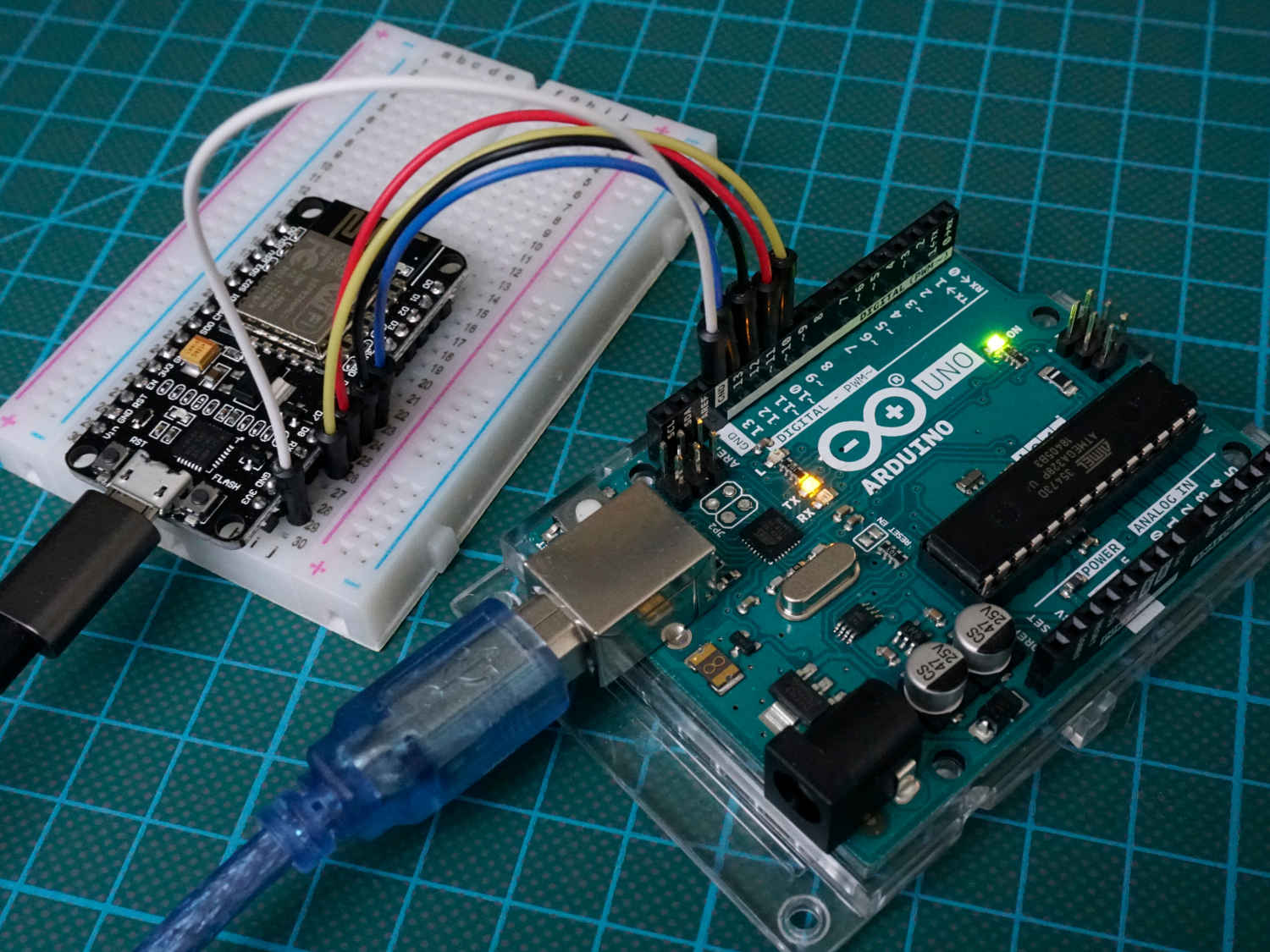

SPI communication: ESP8266 NodeMCU to Arduino Uno

This second example uses the ESP8266 as master because for the slave script we

saw in the first example that the IRS (spi_stc_vect) function is used because

the SPI.attachInterrupt(); statement turns on the interrupt. Unfortunately the

ESP8266 SPI library does not have an attachInterrupt() method and therefore it

is not easy to access the SPI data register for the NodeMCU. Therefore I do not

use ESP8266 NodeMCU as slave device.

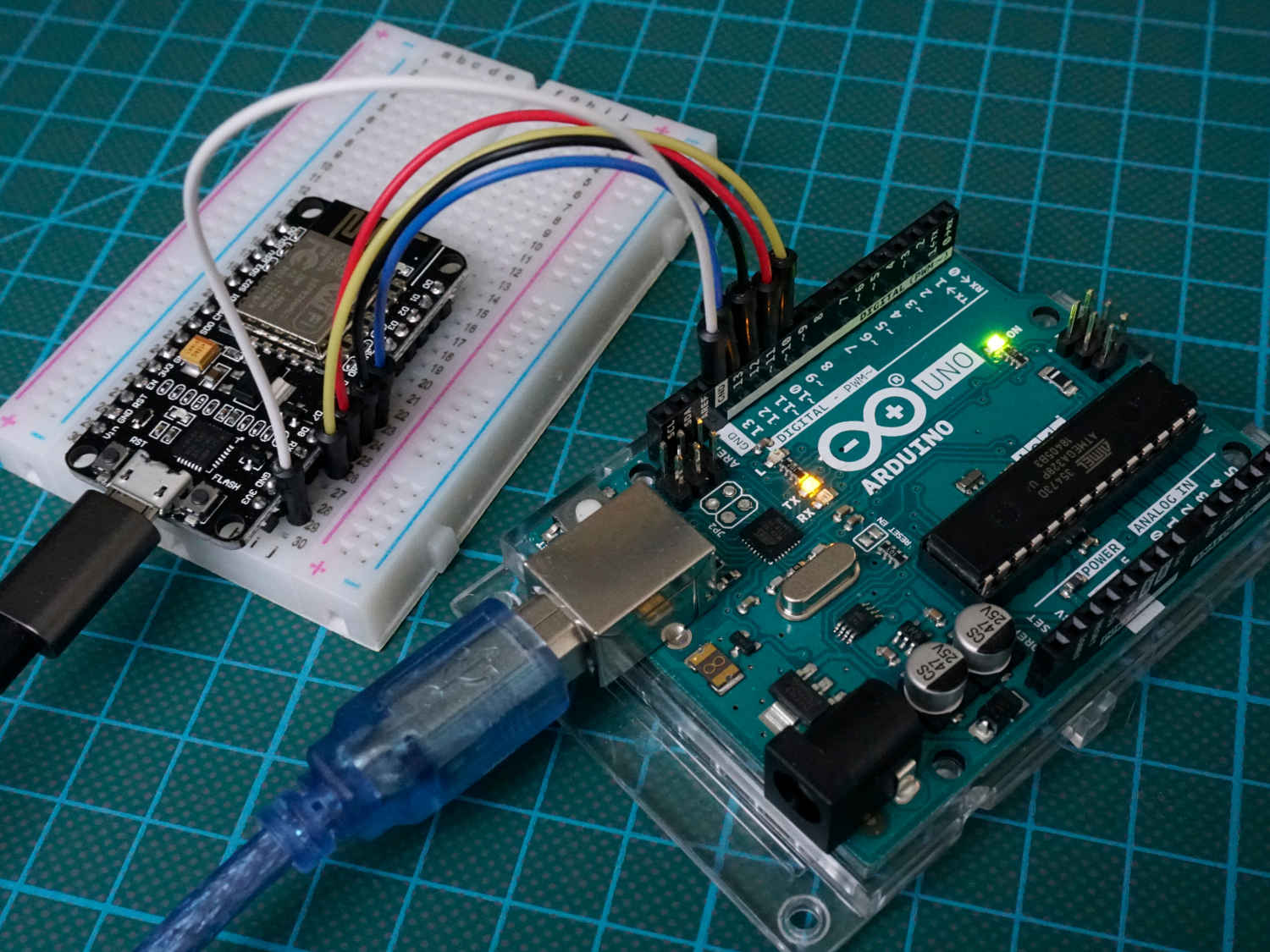

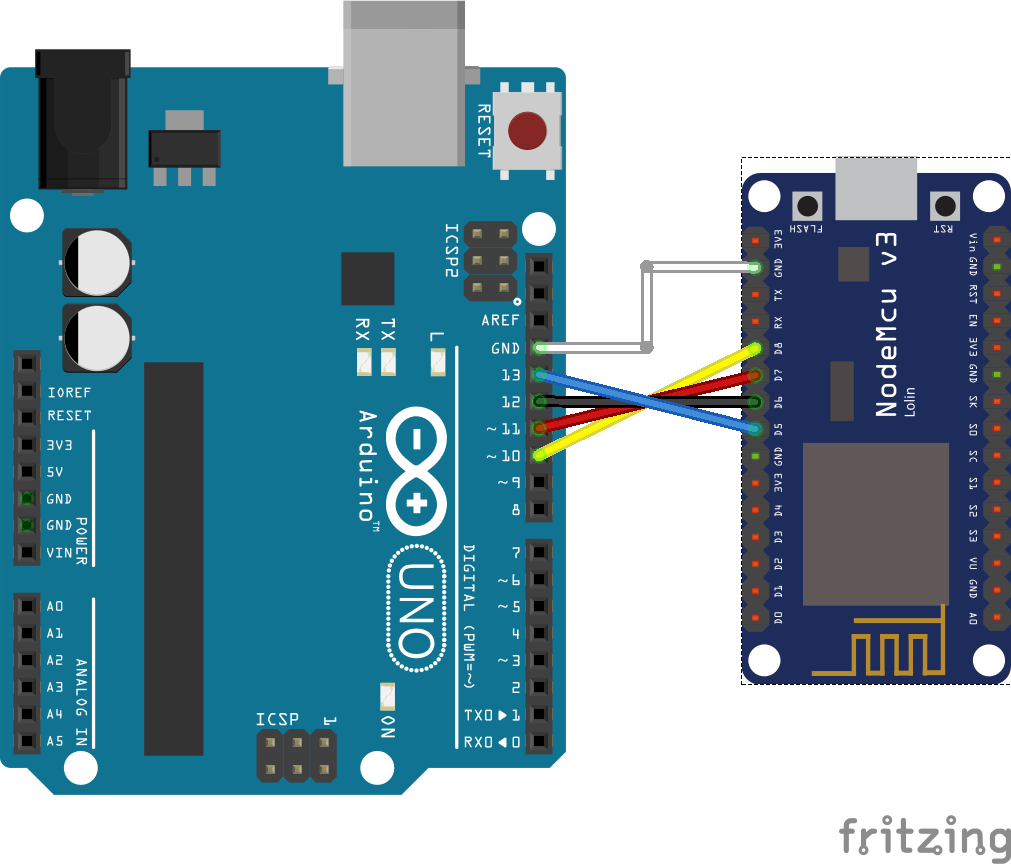

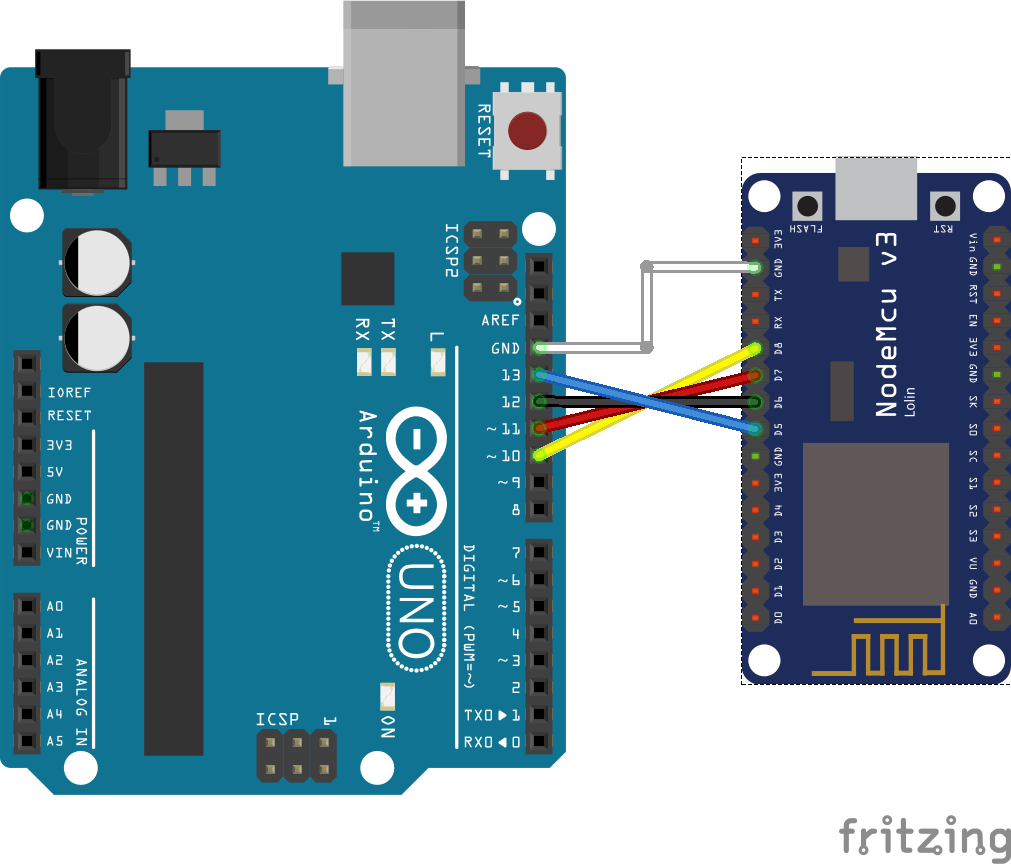

The following picture shows the connection between the ESP8266 NodeMCU and the

Arduino Uno.

SPI NodeMCU 2 Arduino Uno

It is no problem to connect the Arduino and the NodeMCU directly even if the

operating voltage for the Arduino is 5V and for the NodeMCU is 3.3V because the

NodeMCU digital pins are 5V tolerant and protected from over-voltage.

The program code depends not on the specific micocontroller and therefore you

can use the master and slave script from the previous example. But I want to

show you a very short example for the master script from the ESP8266

microcontroller.

SPI NodeMCU 2 Arduino Uno

It is no problem to connect the Arduino and the NodeMCU directly even if the

operating voltage for the Arduino is 5V and for the NodeMCU is 3.3V because the

NodeMCU digital pins are 5V tolerant and protected from over-voltage.

The program code depends not on the specific micocontroller and therefore you

can use the master and slave script from the previous example. But I want to

show you a very short example for the master script from the ESP8266

microcontroller.

#include "SPI.h"

char Buff[]="Hello Slave\n";

/*F********************************************************************

*

**********************************************************************/

void

setup()

{

SPI.begin();

}

/*F********************************************************************

*

**********************************************************************/

void

loop()

{

for( int i =0; i < sizeof Buff; i++)

SPI.transfer( Buff[i] );

delay( 1000 );

}

At the beginning we include the SPI library and the character array which holds

the characters we want to transfer to the slave device. In the setup function we

only initialize the SPI communication. In the loop function we transfer the

character array letter by letter via SPI and then wait for 1 second. This is the

shortest master script you can create which uses only the default settings for

the SPI communication.

For the slave script we use the same as for the Arduino Mega.

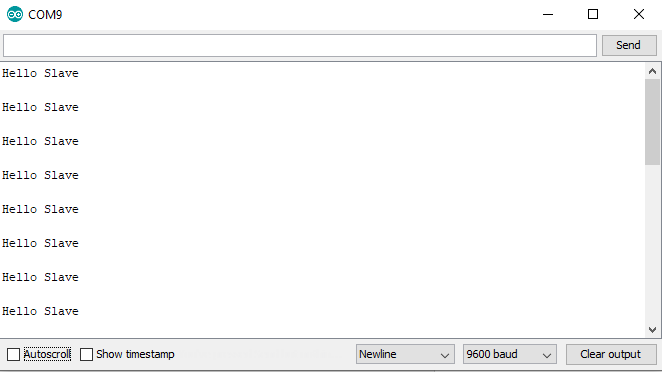

The following picture show the serial output for the SPI communication example

between NodeMCU and Arduino Uno.

NodeMCU 2 Arduino Uno Serial Monitor

NodeMCU 2 Arduino Uno Serial Monitor

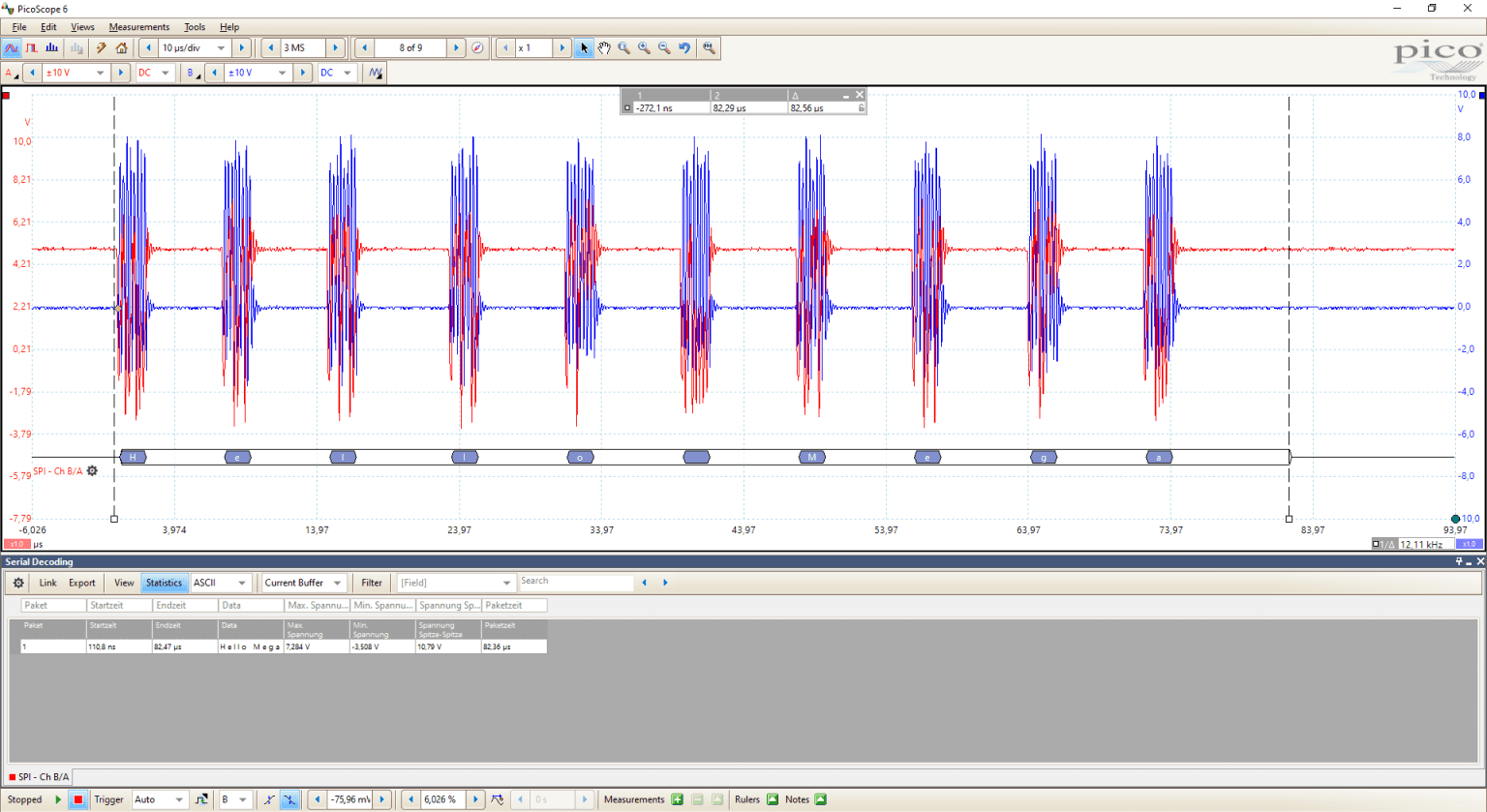

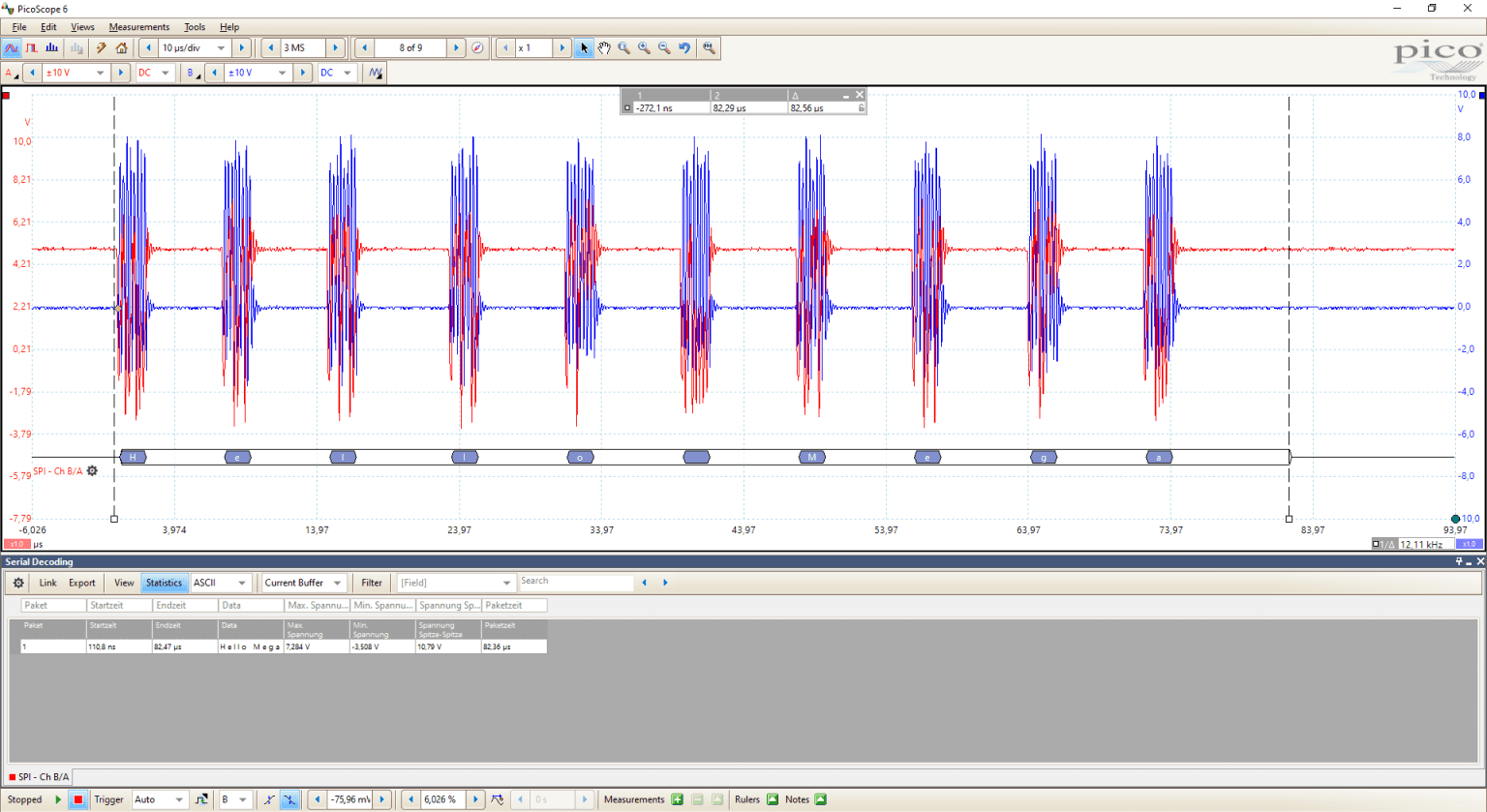

View and Decode SPI Communication with an Oscilloscope

There is also the possibility that the SPI communication fails. If this happens

it is very useful to know if the SPI communication on the MOSI line which is the

output of the master is correct or not. Most oscilloscopes have the function to

decode communication protocols like SPI. I have a 2 channel USB oscilloscope

which is linked at the top of this article in the parts list.

I decoded the first example where we sent “Hello Mega” from the Arduino Uno to

the Arduino Mega. I only connect the MISO and Clock signal each to one channel

of my oscilloscope. In the following picture you see the decoded signal showing

that the output from the Arduino Uno is correct, sending “Hello Mega”.

Click on the image to enlarge it.

SPI Oscilloscope

SPI Oscilloscope

Conclusion

In this tutorial we first compared the SPI communication protocol against I2C

and UART. Also we discussed the SPI settings and how the data is transmitted

between different devices. At the end of this article we looked at two examples

and how SPI communication can be decoded and debugged with the help of an

oscilloscope.

If you have any questions regarding the SPI communication, please use the

comment section below to ask your questions. I will answer them as fast as

possible.

SPI three slaves

Source Picture:

There are 3 lines which connect the master device to all slave devices

MISO (Master in Slave Out): The Slave line for sending data to the master

MOSI (Master Out Slave In): The Master line for sending data to the peripherals

SCK/SCLK (Serial Clock): The pulse from the master device to synchronize

data transmission

And 1 line from the master to each device

SS (Slave Select) One specific line to each peripheral that the master can

enable or disable the specific slave. This allows to share the MISO, MOSI and

SCK line between multiple devices. The SS pin can be any digital pin on your

microcontroller

SS Pin is LOW → Slave communication to master is enabled

SS Pin is HIGH → Slave communication to master is disabled

If you want to know what are the MISO, MOSI and SCK pins for different microcontrollers, you find this information in the related pinout articles: Arduino Mega, Arduino Uno, Arduino Nano, ESP8266 NodeMCU or better if you download the Microcontroller Datasheet eBook.

Microcontroller Datasheet eBook

The 35 pages Microcontroller Datasheet Playbook contains the most useful information of 14 Arduino, ESP8266 and ESP32 microcontroller boards.

Get more Information

SPI three slaves

Source Picture:

There are 3 lines which connect the master device to all slave devices

MISO (Master in Slave Out): The Slave line for sending data to the master

MOSI (Master Out Slave In): The Master line for sending data to the peripherals

SCK/SCLK (Serial Clock): The pulse from the master device to synchronize

data transmission

And 1 line from the master to each device

SS (Slave Select) One specific line to each peripheral that the master can

enable or disable the specific slave. This allows to share the MISO, MOSI and

SCK line between multiple devices. The SS pin can be any digital pin on your

microcontroller

SS Pin is LOW → Slave communication to master is enabled

SS Pin is HIGH → Slave communication to master is disabled

If you want to know what are the MISO, MOSI and SCK pins for different microcontrollers, you find this information in the related pinout articles: Arduino Mega, Arduino Uno, Arduino Nano, ESP8266 NodeMCU or better if you download the Microcontroller Datasheet eBook.

Microcontroller Datasheet eBook

The 35 pages Microcontroller Datasheet Playbook contains the most useful information of 14 Arduino, ESP8266 and ESP32 microcontroller boards.

Get more Information

Modes of Transmission

Modes of Transmission

Source Picture

The data which is transferred via SPI communication is stored in 8-bit or 16-bit

shift registers which have the same length for the master and slave device. Data

is usually shifted out with the most significant bit first, defined by the SPI

settings and stored as the new last significant bit of the shift register. The

SPI module is unBuffered in the transmit direction and single Buffered in the

received direction. The following 6 steps describe the SPI data transmission:

First the master device configures the SPI settings (clock rate, data

shifting, mode of transmission).

The master selects the slave device by pulling the SS line LOW (from logical

1 to logical 0).

The following steps are done all at the same time during one clock cycle on

a full-duplex data transmission:

On the clock edge, the master sends the first bit to the slave via the

MOSI line. The slave reads the incoming message.

On the clock edge, the slave sends the first bit to the master via the

MISO line. The master reads the incoming message.

The data exchange is done, when the complete shift register is transmitted.

The whole shift register is then copied into the receive Buffer and the

shift registers are reloaded. The data transmission processes starts again.

If the transmission is complete, the master stops the clock signal and stops

pulling the SS line LOW.

Source Picture

The data which is transferred via SPI communication is stored in 8-bit or 16-bit

shift registers which have the same length for the master and slave device. Data

is usually shifted out with the most significant bit first, defined by the SPI

settings and stored as the new last significant bit of the shift register. The

SPI module is unBuffered in the transmit direction and single Buffered in the

received direction. The following 6 steps describe the SPI data transmission:

First the master device configures the SPI settings (clock rate, data

shifting, mode of transmission).

The master selects the slave device by pulling the SS line LOW (from logical

1 to logical 0).

The following steps are done all at the same time during one clock cycle on

a full-duplex data transmission:

On the clock edge, the master sends the first bit to the slave via the

MOSI line. The slave reads the incoming message.

On the clock edge, the slave sends the first bit to the master via the

MISO line. The master reads the incoming message.

The data exchange is done, when the complete shift register is transmitted.

The whole shift register is then copied into the receive Buffer and the

shift registers are reloaded. The data transmission processes starts again.

If the transmission is complete, the master stops the clock signal and stops

pulling the SS line LOW.

Arduino Uno 2 Mega

In the following part we go step by step through the program script.

Arduino Uno 2 Mega

In the following part we go step by step through the program script.

SPI NodeMCU 2 Arduino Uno

It is no problem to connect the Arduino and the NodeMCU directly even if the

operating voltage for the Arduino is 5V and for the NodeMCU is 3.3V because the

NodeMCU digital pins are 5V tolerant and protected from over-voltage.

The program code depends not on the specific micocontroller and therefore you

can use the master and slave script from the previous example. But I want to

show you a very short example for the master script from the ESP8266

microcontroller.

SPI NodeMCU 2 Arduino Uno

It is no problem to connect the Arduino and the NodeMCU directly even if the

operating voltage for the Arduino is 5V and for the NodeMCU is 3.3V because the

NodeMCU digital pins are 5V tolerant and protected from over-voltage.

The program code depends not on the specific micocontroller and therefore you

can use the master and slave script from the previous example. But I want to

show you a very short example for the master script from the ESP8266

microcontroller.

NodeMCU 2 Arduino Uno Serial Monitor

NodeMCU 2 Arduino Uno Serial Monitor

SPI Oscilloscope

SPI Oscilloscope